OECT vs OFET Biosensors: A Comparative Guide for Biomedical Researchers and Developers

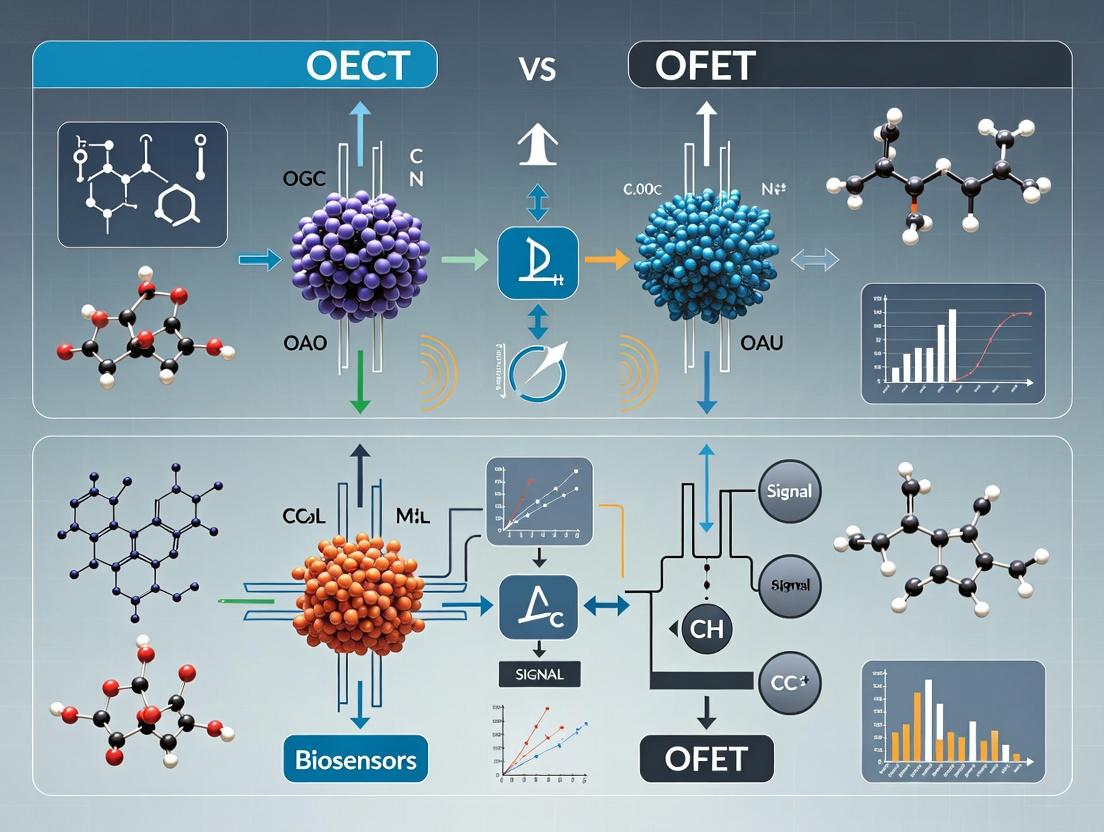

This article provides a comprehensive, up-to-date comparison of Organic Electrochemical Transistors (OECTs) and Organic Field-Effect Transistors (OFETs) as biosensing platforms.

OECT vs OFET Biosensors: A Comparative Guide for Biomedical Researchers and Developers

Abstract

This article provides a comprehensive, up-to-date comparison of Organic Electrochemical Transistors (OECTs) and Organic Field-Effect Transistors (OFETs) as biosensing platforms. Tailored for researchers, scientists, and drug development professionals, it explores the foundational device physics and materials, details fabrication methods and real-world applications, addresses common challenges and optimization strategies, and delivers a critical, side-by-side analysis of performance metrics and validation protocols. The synthesis offers actionable insights for selecting and advancing the optimal technology for specific biomedical sensing needs.

Unpacking the Core: The Physics and Materials Behind OECT and OFET Biosensors

The evolution of organic bioelectronics has yielded two principal transistor architectures for biosensing: Organic Electrochemical Transistors (OECTs) and Organic Field-Effect Transistors (OFETs). A fundamental distinction underpinning their operational differences lies in their gating mechanism: OECTs primarily utilize volumetric (bulk) gating, while OFETs operate via surface (interfacial) gating. This whitepaper dissects these core principles, framing them within the critical research thesis of selecting the optimal transducer for specific biosensing applications, particularly in pharmaceutical development.

Core Operational Principles

Volumetric Gating (OECT Paradigm)

In OECTs, the organic semiconductor channel (e.g., PEDOT:PSS) is ionically permeable and hydrated. Upon application of a gate voltage, electrolyte ions (e.g., Na+, Cl-) migrate into the bulk of the organic semiconductor film, dedoping/doping it throughout its entire volume. This reversible electrochemical process modulates the channel's electronic conductivity by changing the density of charge carriers (holes for PEDOT:PSS) across the film thickness.

- Key Characteristic: The capacitance is an ionic charge double-layer (EDL) capacitance in series with a volumetric capacitance, leading to very high total capacitance (~mF cm⁻²). The transconductance (gm) scales with channel volume.

Surface Gating (OFET Paradigm)

In OFET-based biosensors, the organic semiconductor (e.g., pentacene, DPPT-TT) is typically ion-impermeable. The gating effect occurs at the interface between the semiconductor and a dielectric layer (or electrolyte). Charge carriers are induced or depleted within the first few molecular layers (~1-3 nm) of the semiconductor, forming a conducting channel. In electrolyte-gated OFETs (EGOFETs), ions in the electrolyte form an EDL at the semiconductor surface, but do not penetrate the bulk.

- Key Characteristic: The capacitance is limited to the interfacial EDL capacitance (~µF cm⁻²). The transconductance depends on the semiconductor's mobility and the quality of the interface.

Quantitative Comparison

Table 1: Core Characteristics of Volumetric vs. Surface Gating

| Parameter | Volumetric Gating (OECT) | Surface Gating (OFET/EGOFET) |

|---|---|---|

| Gating Region | Entire bulk of the channel (3D) | Interface/Surface only (2D) |

| Ion Penetration | Deep, reversible penetration | No penetration (planar EDL) |

| Typical Capacitance | 1 - 10 mF cm⁻² | 1 - 10 µF cm⁻² |

| Transconductance (gm) | Very high (mS range) | Moderate (µS range) |

| Operating Voltage | Low (< 1 V) | Low to Moderate (< 3 V) |

| Channel Material | Mixed ionic-electronic conductor (MIEC) | Primarily electronic conductor |

| Biosensing Relevance | Sensitive to ionic flux & bulk property changes | Sensitive to surface potential & binding events |

| Response to pH/ Ionic Strength | Strong | Weak (unless interface is functionalized) |

Table 2: Implications for Biosensing in Drug Development Research

| Aspect | OECT (Volumetric) | OFET (Surface) |

|---|---|---|

| Target Size | Excellent for cells, large biomolecules, and metabolites | Optimal for small molecules, proteins, DNA (surface binding) |

| Signal Amplification | Exceptional due to high gm | Good, but typically lower |

| Integration with Aqueous Media | Inherently excellent | Requires careful dielectric/interface engineering |

| Spatial Resolution (e.g., for cell mapping) | Lower (bulk effect blurs localized signals) | Higher (localized surface effect) |

| Long-term Stability in Buffer | Can suffer from gradual volumetric swelling/degradation | Generally more stable, dependent on encapsulation |

Experimental Protocols for Characterization

Protocol 1: Measuring Volumetric Gating in OECTs

Objective: To characterize the bulk doping/dedoping process and extract relevant figures of merit. Materials: See "Scientist's Toolkit" (Table 3). Methodology:

- Device Fabrication: Pattern source/drain electrodes (Au) on a substrate. Spin-coat or screen-print the MIEC (e.g., PEDOT:PSS) channel. Define a well for the electrolyte and integrate a gate electrode (Ag/AgCl or Pt).

- Electrical Setup: Connect to a source measure unit (SMU) in a 3-terminal configuration (Source, Drain, Gate). Place the device in phosphate-buffered saline (PBS).

- Transfer Curve Measurement: Sweep the gate voltage (VG) from positive to negative (e.g., +0.6 V to -0.8 V) while maintaining a constant small drain voltage (VDS, e.g., -0.1 V). Record the drain current (I_D).

- Output Curve Measurement: At fixed VG steps, sweep VDS and record I_D.

- Key Analysis:

- Calculate peak transconductance: gm = δID / δVG.

- Determine the response time by applying a gate voltage step and measuring the temporal I_D response.

- Perform electrochemical impedance spectroscopy (EIS) to quantify the channel capacitance.

Protocol 2: Measuring Surface Gating in EGOFETs

Objective: To characterize interfacial gating and extract mobility and threshold voltage. Materials: See "Scientist's Toolkit" (Table 3). Methodology:

- Device Fabrication: Pattern source/drain electrodes (Au) on a substrate. Deposit a thin film of organic semiconductor (e.g., via thermal evaporation or solution-shearing). Define a well for the electrolyte and integrate a gate electrode.

- Electrical Setup: Similar to OECT setup but with careful shielding to minimize noise.

- Transfer Curve Measurement: Sweep VG while measuring ID at constant V_DS (in the linear regime, e.g., -0.1 V). Use a slower sweep rate to allow EDL formation.

- Key Analysis:

- Plot √|ID| vs. VG in the saturation regime to extract the charge carrier mobility (µ) and threshold voltage (V_Th) using the standard FET equation.

- Calculate interfacial capacitance via C-V measurements or EIS.

Visualization of Operational Principles

Diagram 1: OECT Volumetric Gating Mechanism (77 chars)

Diagram 2: OFET Surface Gating Mechanism (73 chars)

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for OECT/OFET Biosensor Research

| Item | Function & Relevance | Example/Notes |

|---|---|---|

| PEDOT:PSS Dispersion | The canonical MIEC for OECTs. Provides high volumetric capacitance and ionic permeability. | Clevios PH1000, often mixed with ethylene glycol and cross-linkers for stability. |

| High-Mobility p/n-type OSC | For OFET channels. Determines baseline electronic performance (mobility, on/off ratio). | DPPT-TT (p-type), N2200 (n-type), evaporated pentacene. |

| Ion-Selective/Functionalized Membranes | To impart specificity in biosensors. Converts biological event into ionic or potentiometric signal. | Nafion (cation selector), lipid bilayers, immobilized enzymes or antibodies. |

| Stable Gate Electrodes | Provides stable potential in electrolyte. Critical for reproducible gating. | Ag/AgCl wire or patterned electrode, Platinum wire. |

| Physiological Buffer Salts | Electrolyte for gating and biomolecule environment. Ionic strength directly affects OECT response. | Phosphate Buffered Saline (PBS), Artificial Interstitial Fluid. |

| Cross-linkers & Additives | Stabilize MIEC films in aqueous media (for OECTs) or improve OSC morphology (for OFETs). | (3-glycidyloxypropyl)trimethoxysilane (GOPS), divinyl sulfone (DVS), surfactants. |

| Microfluidic Encapsulation | Defines electrolyte area, enables fluidic handling, and protects sensitive components. | PDMS gaskets, epoxy-based photoresists (e.g., SU-8). |

This whitepaper provides an in-depth technical analysis of the core architectural components—channel, electrolyte, and gate electrode—in Organic Electrochemical Transistors (OECTs), framed within a broader research thesis contrasting OECT and Organic Field-Effect Transistor (OFET) biosensors. The unique operational paradigm of OECTs, based on volumetric ion-to-electron transduction within an organic mixed conductor, fundamentally distinguishes them from the surface-dominated electrostatics of OFETs. This guide details material considerations, operational mechanisms, quantitative performance parameters, and experimental protocols for characterizing these core elements, serving as a resource for researchers and drug development professionals advancing bioelectronic sensing platforms.

The selection between OECT and OFET architectures for biosensing applications hinges on fundamental transduction mechanisms. OFETs, operating via field-effect modulation of charge carriers in a thin conduction channel, are exquisitely sensitive to surface potentials and binding events at the dielectric/semiconductor interface. In contrast, OECTs operate via the reversible, volumetric electrochemical doping/dedoping of an organic semiconductor channel by ions from an electrolyte. This bulk penetration of ions (typically from a biologically relevant aqueous medium) renders OECT transconductance several orders of magnitude higher than OFETs at low operating voltages (<1 V), making them exceptionally sensitive to ionic and biochemical fluctuations. This document deconstructs the three pillars enabling this performance: the mixed ionic-electronic conducting channel, the ionically conductive electrolyte, and the gate electrode governing ion injection.

The Mixed Ionic-Electronic Conducting (MIEC) Channel

The channel material is the cornerstone of OECT performance. It must facilitate both electronic (hole/electron) transport and ion penetration/transport. Semiconducting polymers like poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) are quintessential, where PSS provides ionic conduction pathways and PEDOT provides electronic conduction.

Key Material Parameters:

- Ionic Conductivity (σᵢ): Dictates ion penetration speed and device transient response.

- Electronic Conductivity (σₑ): Determines the ON-current and electronic mobility.

- Volumetric Capacitance (C): The charge stored per unit volume per volt, a defining figure of merit. Higher C enables greater modulation for a given voltage.

- Swelling Ratio: The degree of volumetric expansion upon electrolyte uptake, affecting device stability and kinetics.

Table 1: Common OECT Channel Materials and Key Properties

| Material System | Ionic Conductivity (σᵢ) | Electronic Conductivity (σₑ) | Volumetric Capacitance (C*) | Primary Application |

|---|---|---|---|---|

| PEDOT:PSS (high-cond.) | ~0.1 S/cm | ~100-1000 S/cm | ~40-100 F/cm³ | General biosensing, amplifiers |

| PEDOT:PSS (glycol-treated) | ~0.2 S/cm | ~1000 S/cm | ~100-200 F/cm³ | High-sensitivity metabolite sensing |

| p(g2T-TT) / p(g2T-TT)-T | ~10⁻³ S/cm | ~10⁻² S/cm | ~200-300 F/cm³ | N-type OECTs, complementary logic |

| PEDOT:PSS / Ion Gel | ~1 S/cm | ~500 S/cm | >300 F/cm³ | High-frequency operation |

Experimental Protocol: Channel Characterization via Electrochemical Impedance Spectroscopy (EIS)

Objective: To determine the volumetric capacitance (C*) and ionic resistance of a channel material. Materials: Channel film on patterned Au electrodes, reference electrode (e.g., Ag/AgCl), counter electrode (Pt wire), electrolyte (e.g., 0.1 M NaCl). Procedure:

- Configure a 3-electrode cell with the channel film as the working electrode.

- Apply a small AC voltage perturbation (e.g., 10 mV RMS) across a frequency range (e.g., 1 MHz to 0.1 Hz) at a set DC bias (e.g., 0 V vs. Ag/AgCl).

- Measure impedance (Z) and phase (θ).

- Fit the Nyquist plot to an equivalent circuit model (e.g., a resistor in series with a constant phase element (CPE) parallel to another resistor).

- Extract the effective capacitance from the CPE parameters. Normalize by the channel volume to obtain C*.

Diagram 1: EIS protocol for channel characterization

The Electrolyte

The electrolyte is the ionic charge transport medium and the biorecognition element host. Its composition directly influences OECT operation, sensitivity, and biocompatibility.

Critical Factors:

- Ionic Strength: Affects Debye length and the sensing window for charged analytes.

- pH and Buffer Capacity: Critical for maintaining biological activity and interpreting sensor response.

- Specific Ion Effects: Ion size and hydration shell affect penetration into the channel.

Table 2: Electrolyte Compositions for OECT Biosensing

| Electrolyte Type | Primary Composition | Typical Concentration | Key Role/Consideration |

|---|---|---|---|

| Physiological Buffer | Phosphate Buffered Saline (PBS) | 0.01M - 0.1M | Baseline for in vitro biosensing, controls ionic strength & pH. |

| Cell Culture Medium | DMEM, RPMI with supplements | Variable (ionic ~0.15M) | For real-time cell monitoring; complex, may contain interferents. |

| Specific Ion Solution | NaCl, KCl | 1 mM - 1 M | For characterizing fundamental ion sensitivity (cation vs. anion). |

| Functionalized Electrolyte | PBS with enzymes/aptamers | Varies | Contains biorecognition element for specific analyte detection. |

The Gate Electrode

The gate electrode controls ion injection into the channel. Its potential governs the electrochemical window and can be functionalized to become the primary sensing interface.

Types & Characteristics:

- Non-Functionalized (e.g., Pt, Au): Used for characterizing channel or electrolyte properties. Provides a stable potential via reversible reactions (e.g., H⁺ reduction, oxide formation).

- Functionalized Gates: The gate surface is modified with receptors (enzymes, antibodies, aptamers). Binding events alter the gate's effective potential, modulating the channel current—a highly sensitive configuration.

- Quasi-Reference Electrodes (Ag/AgCl): Common in integrated setups, providing a stable, low-polarizability reference potential.

Table 3: Gate Electrode Configurations in OECT Biosensors

| Gate Type | Material/Modification | Stability | Typical Use Case | Transduction Mechanism |

|---|---|---|---|---|

| Simple Metal | Pt, Au wire | High | Fundamental studies, ion sensing | Capacitive charging / faradaic reactions |

| Integrated QRE | Patterned Ag/AgCl | Medium-High | Miniaturized, multiplexed devices | Stable reference potential |

| Biofunctionalized | Au with SAM + Antibody | Medium (depends on bio-layer) | Specific antigen detection (e.g., cortisol) | Binding-induced potential shift |

| Enzymatic | Carbon paste with GOx | Low-Medium (enzyme lifetime) | Metabolite sensing (e.g., glucose) | Catalytic reaction product (H₂O₂) |

Experimental Protocol: Gate Functionalization for Aptamer-Based Sensing

Objective: To immobilize thrombin-binding aptamer on a gold gate for specific protein detection. Materials: Au gate electrode, 5'-Thiol-modified aptamer, 6-mercapto-1-hexanol (MCH), Tris-EDTA buffer, thrombin protein solution.

Procedure:

- Clean Au Gate: Sonicate in acetone, ethanol, and DI water. Treat with UV-Ozone for 15 min.

- Aptamer Immobilization: Incubate gate in 1 µM thiol-aptamer solution in TE buffer for 2 hours at room temperature. This forms a self-assembled monolayer (SAM) via Au-S bonds.

- Backfilling: Rinse and incubate in 1 mM MCH solution for 1 hour to displace non-specifically adsorbed aptamers and create a well-ordered, bio-inert monolayer.

- Rinsing & Storage: Rinse thoroughly with buffer and store in clean buffer at 4°C until use.

- Measurement: Record OECT transfer characteristics (Iₛₜ vs. V₉) before and after exposure to thrombin solutions of varying concentration.

Diagram 2: Aptamer gate functionalization workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for OECT Fabrication & Characterization

| Item | Function | Example Product/Specification |

|---|---|---|

| Conductive Polymer | Forms the OECT channel. | Heraeus Clevios PH1000 (PEDOT:PSS), 1.3% in H₂O. |

| Ionic Additive | Enhances film conductivity & stability. | Ethylene Glycol (99.8%), DMSO, or surfactant Zonyl FS-300. |

| Crosslinker | Reduces film dissolution/swelling in electrolyte. | (3-Glycidyloxypropyl)trimethoxysilane (GOPS). |

| High-Resolution Photoresist | For patterning micro-scale channels/gates. | MicroChem SU-8 2000 series or LOR series. |

| Gate Electrode Material | Provides stable potential/functionalization site. | Pt/Ir wire (0.127 mm dia.), Ag/AgCl pellet, patterned Au on glass. |

| Biological Buffer | Provides stable ionic background for biosensing. | 1X PBS, pH 7.4, sterile-filtered. |

| Surface Modifier | Enables bioreceptor immobilization on Au gates. | 11-mercaptoundecanoic acid (11-MUA) for EDC/NHS coupling. |

| Blocking Agent | Reduces non-specific binding on sensor surfaces. | Bovine Serum Albumin (BSA), fraction V. |

| Electrochemical Cell | Holds electrolyte for device testing. | Custom 3D-printed well or commercial electrochemical cell. |

| Source/Measure Unit | Applies Vds/Vgs and measures Ids. | Keithley 2400/2600 Series SMU or Palmsens4 potentiostat. |

This whitepaper details the core architecture of Organic Field-Effect Transistors (OFETs), framed within a broader thesis investigating the fundamental differences between OFET and Organic Electrochemical Transistor (OECT)-based biosensors. For biosensing applications, the solid-state, three-terminal OFET structure contrasts sharply with the volumetric ionic-electronic coupling in OECTs, defining distinct operational mechanisms and sensor design philosophies.

Core Components and Their Functions

The performance of an OFET biosensor is governed by the synergistic interaction of its three core layers: the semiconductor, the dielectric, and the electrodes.

Organic Semiconductor (OSC)

The OSC layer is the charge-transporting heart of the OFET. In a biosensor context, it also often serves as the primary site for biorecognition event transduction. The two primary architectures are:

- Bottom-gate: OSC deposited on top of the dielectric.

- Top-gate: OSC deposited on the substrate, followed by dielectric and gate electrode.

Commonly used OSCs include polymers like P3HT, PEDOT:PSS (for hole transport), and small molecules like pentacene or C60 derivatives (for electron transport). Recent trends focus on donor-acceptor copolymers (e.g., DPP-based polymers) with tailored energy levels for ambient stability and specific interactions with analytes.

Dielectric Layer

The dielectric electrically insulates the semiconductor from the gate electrode while capacitively coupling them. Its properties critically affect the operating voltage and interfacial trap states.

- Inorganic Dielectrics: SiO₂, Al₂O₃, HfO₂. Offer high capacitance but rigid, high-temperature processing.

- Polymer Dielectrics: PMMA, PVP, CYTOP, parylene C. Enable low-voltage operation, flexibility, and solution processability. Parylene C is particularly favored in biosensing for its excellent biocompatibility and conformal coating ability.

- Electrolyte Dielectrics: Ionic liquids/gels. Enable ultra-high capacitance, leading to very low operating voltages (<1 V) and creating a hybrid OFET/OECT operational mode.

Electrodes (Source, Drain, Gate)

Electrodes inject and extract charge carriers from the OSC. The work function of the source/drain electrodes must align with the HOMO (p-type) or LUMO (n-type) levels of the OSC for efficient charge injection.

- Common Materials: Au (high work function, for p-type), Ca/Al (low work function, for n-type), ITO (transparent). In biosensors, Au is often functionalized with biorecognition elements (e.g., antibodies, aptamers).

- Gate Electrode: Can be a metal (Al, Au) or, in liquid-gated configurations, a reference electrode like Ag/AgCl.

Quantitative Performance Parameters & Comparison

Key performance metrics for OFETs in biosensing are summarized below. These parameters are directly modulated by biorecognition events (e.g., binding of a target biomolecule to the functionalized gate/ semiconductor surface), producing the sensor signal.

Table 1: Key OFET Performance Metrics and Typical Ranges

| Parameter | Symbol | Definition | Typical Range (OFET Biosensors) | Impact of Biomolecular Binding |

|---|---|---|---|---|

| Field-Effect Mobility | μ (cm²/V·s) | Charge carrier drift velocity per unit electric field. | 10⁻³ to >10 cm²/V·s | Decrease due to introduced scattering or trap sites. |

| Threshold Voltage | V_T (V) | Gate voltage required to turn on the channel. | -5 V to +5 V | Shift due to change in interfacial charge or capacitance. |

| On/Off Current Ratio | ION/IOFF | Ratio of maximum to minimum channel current. | 10³ to 10⁸ | Decrease if binding increases off-current or decreases on-current. |

| Subthreshold Swing | SS (mV/dec) | Gate voltage needed to increase current by one decade. | 100 - 2000 mV/dec | Increase if binding introduces additional interface traps. |

| Operational Voltage | VDS, VGS (V) | Voltages applied during operation. | < 5 V (Polymer dielectric) < 1 V (Electrolyte gate) | N/A |

Table 2: Core Material Choices for OFET Biosensors

| Component | Material Options | Key Properties for Biosensing | Common Deposition Methods |

|---|---|---|---|

| Semiconductor | P3HT, DPP-DTT, Pentacene, N2200 | Energy level alignment, environmental stability, surface functionality for bioreceptor attachment. | Spin-coating, Inkjet printing, Vacuum evaporation. |

| Dielectric | Parylene C, PMMA, CYTOP, SiO₂, Ionic Gel | Biocompatibility, low leakage, high capacitance, stability in aqueous media. | CVD (parylene), Spin-coating, Thermal evaporation. |

| Electrodes | Au, Pt, ITO, PEDOT:PSS | Work function, chemical stability, ease of functionalization (e.g., Au-thiol chemistry). | Thermal evaporation, Sputtering, Electroplating. |

Experimental Protocol: Fabrication and Characterization of a Basic OFET Biosensor

A. Substrate Preparation & Gate Electrode Deposition:

- Clean a heavily doped silicon wafer (serves as global gate) or glass/plastic substrate.

- If using a separate gate, deposit and pattern a gate electrode (e.g., 50 nm Au) via photolithography and evaporation.

B. Dielectric Deposition:

- For SiO₂: Thermally oxidize the Si wafer to grow a 100-300 nm oxide layer.

- For polymer dielectric (e.g., PMMA): Spin-coat a 5-10% solution in anisole at 2000-4000 rpm for 60 s. Anneal at 80-100°C for 1 hour to remove solvent.

C. Organic Semiconductor Deposition:

- For polymer OSC (e.g., P3HT): Spin-coat a 1-2% solution in chlorobenzene in a nitrogen glovebox. Anneal at 80-120°C for 30 min.

- For small molecule OSC (e.g., pentacene): Deposit via thermal evaporation at a rate of 0.1-0.3 Å/s under high vacuum to a thickness of 30-50 nm.

D. Source/Drain Electrode Deposition (Top-Contact Geometry):

- Use a shadow mask to define channel length (L) and width (W). Typical L = 20-100 µm, W = 100-5000 µm.

- Thermally evaporate Au (50 nm) through the mask to form electrodes.

E. Biosensor Functionalization (Example: Streptavidin-Biotin Model):

- Treat the Au S/D electrodes or the OSC surface with a thiolated or silane-based linker molecule (e.g., 11-mercaptoundecanoic acid) for 12 hours.

- Activate carboxyl groups with a mixture of EDC and NHS for 1 hour.

- Immerse the OFET in a solution of streptavidin (10 µg/mL in PBS) for 2 hours. Rinse thoroughly.

- The device is now ready for exposure to biotinylated target analytes.

F. Electrical Characterization:

- Use a semiconductor parameter analyzer (e.g., Keysight B1500A) in a shielded probe station.

- Sweep gate voltage (VGS) at constant drain voltage (VDS) to obtain transfer characteristics (IDS vs VGS).

- Extract μ, VT, ION/IOFF, and SS using standard FET equations:

- μ = (∂√|IDS|/∂VGS)² * (2L)/(W*Ci) (in saturation regime)

- where C_i is the dielectric capacitance per unit area.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagents for OFET Biosensor Development

| Item | Function/Description |

|---|---|

| P3HT (Regioregular) | Benchmark p-type organic semiconductor polymer. |

| Parylene C | USP Class VI biocompatible, vapor-deposited dielectric barrier. |

| Cytop | Low-k, hydrophobic fluoropolymer dielectric, minimizes ion diffusion. |

| (3-Aminopropyl)triethoxysilane (APTES) | Silane coupling agent to introduce amine groups on oxide surfaces for biomolecule conjugation. |

| 1-Pyrenebutanoic acid succinimidyl ester | Non-covalent linker for functionalizing graphene or carbon nanotube-based OSCs via π-π stacking. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard aqueous medium for biological functionalization and measurements. |

| N,N-Dimethylformamide (DMF) / Chlorobenzene | High-purity solvents for dissolving and processing organic semiconductors. |

| Ethylene Diamine Tetraacetic Acid (EDTA) | Chelating agent added to measurement buffers to sequester metal ions that could dope the OSC. |

Schematic Diagrams

OFET Biosensor Structure & Signal Path

OFET vs OECT Transduction Mechanism

Within the comparative research paradigm of Organic Electrochemical Transistors (OECTs) versus Organic Field-Effect Transistors (OFETs) for biosensing applications, the performance, sensitivity, and operational stability are fundamentally governed by the material selection. This whitepaper provides an in-depth technical guide to three core material classes: conducting polymers (the active channel material), ion gels (the gate dielectric/electrolyte), and biocompatible substrates (the foundational support). The synergistic integration of these materials dictates critical differences in OECT and OFET biosensor operation, including transduction mechanism, interface with biological analytes, and device architecture.

Conducting Polymers: The Active Semiconductor

Conducting polymers (CPs) are π-conjugated organic materials that can conduct electronic charge while maintaining mechanical flexibility. Their mixed ionic-electronic conduction properties are central to biosensor function.

Core Properties & Relevance:

- OECTs: Require CPs with high volumetric capacitance and efficient mixed ionic-electronic conduction (MIEC). The benchmark material is poly(3,4-ethylenedioxythiophene) doped with poly(styrene sulfonate) (PEDOT:PSS). Upon application of a gate bias, hydrated ions from the electrolyte penetrate the bulk of the CP film, dedoping it and modulating its electronic conductivity.

- OFETs: Require CPs with high charge carrier mobility and ordered microstructures for efficient lateral charge transport in a thin channel. Materials like poly(3-hexylthiophene) (P3HT) and diketopyrrolopyrrole (DPP)-based polymers are common. Sensing occurs primarily through electrostatic interactions or doping events at the surface of the semiconductor.

Quantitative Comparison of Key Conducting Polymers:

Table 1: Key Properties of Conducting Polymers in OECT vs. OFET Biosensors

| Polymer | Typical OECT µC* (F cm⁻¹ V⁻¹ s⁻¹) | Typical OFET µ (cm² V⁻¹ s⁻¹) | Key Advantages | Primary Biosensor Role |

|---|---|---|---|---|

| PEDOT:PSS | 200 - 400 | 0.01 - 1 | High MIEC, excellent aqueous stability, commercial availability | OECT channel material |

| P3HT | 1 - 10 | 0.01 - 0.1 | Solution processability, well-studied morphology | OFET channel material |

| p(g2T-TT) | 300 - 500 | N/A | Engineered for high OECT performance, glycol side chains | High-performance OECT channel |

| DPP-based | N/A | 0.1 - 5 | High OFET mobility, tunable energy levels | High-performance OFET channel |

µC: Product of mobility (µ) and volumetric capacitance (C), the OECT performance metric.

Experimental Protocol: OECT Channel Deposition (Spin-Coating)

- Substrate Preparation: Clean glass or biocompatible substrate (e.g., PDMS-coated glass) via sequential sonication in detergent, deionized water, acetone, and isopropanol (15 min each). Treat with oxygen plasma for 5 minutes to ensure hydrophilic surface.

- Polymer Solution Preparation: Filter commercially available PEDOT:PSS solution (e.g., Clevios PH1000) through a 0.45 µm PVDF syringe filter. Optionally, mix with 5% v/v ethylene glycol and 1% v/v (3-glycidyloxypropyl)trimethoxysilane (GOPS) as a cross-linker for improved stability.

- Spin-Coating: Dispense 100 µL of solution onto the static substrate. Spin at 3000 rpm for 60 seconds in ambient conditions.

- Annealing: Cure the film on a hotplate at 140°C for 15-60 minutes (longer for GOPS-crosslinked films) to remove residual solvents and induce cross-linking.

Ion Gels: The Gate Dielectric/Electrolyte

Ion gels are quasi-solid composites of an ionic liquid and a gelating polymer matrix (e.g., triblock copolymers). They provide a high-capacitance, stable ionic interface.

Core Properties & Relevance:

- OECTs: Serve as the primary electrolyte, providing mobile ions for channel doping/dedoping. Can be used as a gate electrolyte in a planar architecture.

- OFETs: Function as an ultra-high capacitance (µF cm⁻²) gate dielectric in electrolyte-gated OFETs (EG-OFETs), enabling low-voltage operation (<1 V). This blurs the architectural line with OECTs but retains a surface-dominated transduction mechanism.

Quantitative Comparison of Dielectric/Electrolyte Materials:

Table 2: Comparison of Gate Interface Materials for OECTs and OFETs

| Material | Typical Capacitance | Operating Voltage | Key Feature | Device Type |

|---|---|---|---|---|

| Aqueous Buffer (e.g., PBS) | ~µF cm⁻² (EDL) | 0.5 - 1 V | Biocompatible, directly interfaces with bio-analyte | OECT |

| Ion Gel (e.g., [EMIM][TFSI]/PS-PMMA-PS) | 1 - 10 µF cm⁻² | < 1 V | High capacitance, non-volatile, solid-state | EG-OFET, OECT |

| Traditional Dielectric (e.g., SiO₂) | ~10 nF cm⁻² | 20 - 100 V | Low leakage, well-established process | Conventional OFET |

Experimental Protocol: Ion Gel Preparation & Patterning

- Gel Formation: Dissolve the triblock copolymer polystyrene-poly(methyl methacrylate)-polystyrene (PS-PMMA-PS, 5% w/w) in the ionic liquid 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide ([EMIM][TFSI]) at 90°C with stirring for 2-4 hours until a homogeneous, viscous solution is formed.

- Patterning via Stencil Masking: Place a laser-cut PDMS stencil mask on the target substrate (covering source/drain contacts). Deposit a small amount of the warm ion gel and spread with a doctor blade. Carefully remove the stencil, leaving the gel patterned only over the channel/gate region.

- Solidification: Allow the gel to cool and set at room temperature for 1 hour, forming a solid, rubbery film.

Biocompatible Substrates: The Foundation

Biocompatible substrates provide mechanical support while ensuring device stability and compatibility with biological environments (e.g., cells, tissues, physiological fluids).

Core Properties & Relevance:

- Mechanical Properties: Critical for flexible/wearable sensors or interfacing with soft tissues. Low Young's modulus (e.g., of PDMS) minimizes mechanical mismatch.

- Surface Chemistry: Determines wettability, protein/cell adhesion, and functionalization routes for biorecognition elements (enzymes, antibodies, aptamers).

- Permeability: For implantable or tissue-integrated devices, oxygen and nutrient permeability may be required.

Quantitative Comparison of Substrate Materials:

Table 3: Properties of Common Biocompatible Substrates

| Substrate | Young's Modulus | Optical Transparency | Key Advantage | Best Suited For |

|---|---|---|---|---|

| Polyimide (PI) | 2.5 GPa | Opaque (often) | High thermal/chemical stability, flexible | Chronic implants, flexible electronics |

| Polydimethylsiloxane (PDMS) | 0.5 - 4 MPa | High | Gas permeable, tunable modulus, castable | Cell culture interfaces, epidermal sensors |

| Polyethylene Naphthalate (PEN) | ~5 GPa | High | Good moisture barrier, flexible | Flexible, encapsulated biosensors |

| Parylene C | 2.8 GPa | High | Conformal coating, USP Class VI biocompatible | Chronic neural implants, barrier coating |

Experimental Protocol: PDMS Substrate Preparation & Functionalization

- Mixing & Degassing: Mix PDMS base and curing agent (Sylgard 184) at a 10:1 (w/w) ratio. Mix thoroughly, then place in a desiccator connected to a vacuum pump for 30-45 minutes until all bubbles are removed.

- Casting & Curing: Pour the degassed PDMS onto a clean silicon wafer or petri dish. Cure at 65°C for at least 4 hours (or 2 hours at 90°C).

- Surface Activation: Expose the PDMS surface to oxygen plasma (50 W, 30 seconds) to create a transient silanol (Si-OH) rich, hydrophilic surface.

- Biofunctionalization: Immediately immerse the activated PDMS in a 1% (v/v) solution of (3-aminopropyl)triethoxysilane (APTES) in ethanol for 1 hour. Rinse with ethanol and dry. This creates an amine-terminated surface for subsequent covalent immobilization of biorecognition elements via cross-linkers like glutaraldehyde.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Fabrication and Characterization

| Item (Supplier Example) | Function/Benefit |

|---|---|

| Clevios PH1000 PEDOT:PSS (Heraeus) | Industry-standard, high-conductivity polymer dispersion for OECT channels. |

| Ionic Liquid [EMIM][TFSI] (Sigma-Aldrich/Iolitec) | High-stability, low-volatility ionic liquid for formulating ion gels. |

| PS-PMMA-PS Triblock Copolymer (Polymer Source) | Effective gelling agent for ionic liquids to form mechanically robust ion gels. |

| Sylgard 184 Silicone Elastomer Kit (Dow) | The benchmark PDMS for flexible, biocompatible substrates and microfluidics. |

| (3-Glycidyloxypropyl)trimethoxysilane (GOPS) (Sigma-Aldrich) | Cross-linker for PEDOT:PSS, dramatically improving aqueous operational stability. |

| Phosphate Buffered Saline (PBS), 10X Solution (Thermo Fisher) | Standard physiological buffer for electrolyte and device testing in biologically relevant conditions. |

| Poly-L-lysine Solution (Sigma-Aldrich) | Promotes adhesion of cells or proteins to substrate surfaces for cell-based sensing. |

Visualizing Material Roles in OECT vs. OFET Biosensing

This whitepaper provides a technical guide to the conversion of biological recognition events into quantifiable electronic signals within biosensing platforms. The process—termed the signal transduction pathway—is central to the function of all biosensors. The content is framed within a critical research thesis comparing Organic Electrochemical Transistors (OECTs) and Organic Field-Effect Transistors (OFETs), highlighting how their distinct operational principles dictate the design and efficiency of this pathway for applications in biomedical research and drug development.

The Core Transduction Pathway: A Generic Framework

At its essence, a biosensor's signal transduction pathway follows a defined sequence:

Biological Recognition Event (Bioreceptor-Target Binding) → Transducer-Specific Biophysical Change → Electronic Signal → Processed Readout.

The critical divergence between OECTs and OFETs occurs at the Transducer-Specific Biophysical Change stage, fundamentally altering sensitivity, operational environment, and application scope.

Diagram Title: Generic Biosensor Transduction Cascade

Transduction Mechanisms: OECT vs. OFET

Organic Electrochemical Transistor (OECT) Pathway

In OECTs, the organic polymer channel (e.g., PEDOT:PSS) is in direct contact with an electrolyte. The biological event modulates ionic fluxes at the gate or channel interface.

Pathway: Binding Event → Change in Local Ionic Concentration/Potential → Ionic Flux into/out of Polymer Channel → Dedoping/Doping of Channel (Bulk Property Change) → Large Modulation of Channel Conductance ((I_{DS})).

Key Advantage: The mixed ionic-electronic coupling enables very high transconductance (sensitivity to ionic changes) and operation in aqueous, physiological environments.

Organic Field-Effect Transistor (OFET) Pathway

In OFETs, the organic semiconductor channel is typically shielded from the electrolyte by a dielectric. The biological event acts as a gate potential modulator.

Pathway: Binding Event → Introduction or Induction of Charged Species (at Dielectric Surface) → Capacitive Coupling & Field-Effect in Channel → Change in Charge Carrier Density at Semiconductor/Dielectric Interface ((VT) shift or (I{DS}) change).

Key Advantage: The field-effect mechanism offers fast electronic switching and potential for high spatial density in sensor arrays.

Diagram Title: OECT vs. OFET Transduction Mechanisms

Quantitative Comparison of Key Performance Metrics

Table 1: Performance Characteristics of OECT vs. OFET Biosensors

| Performance Metric | OECT Biosensors | OFET Biosensors | Implication for Signal Transduction |

|---|---|---|---|

| Transconductance (gm) | Very High (1-100 mS) | Moderate (0.01-1 µS) | OECTs provide superior signal amplification per input voltage change, ideal for low-concentration analytes. |

| Operating Voltage | Low (< 1 V) | Moderate to High (1-50 V) | OECTs are more suitable for implantable or wearable applications due to low power and safety. |

| Response Time | Milliseconds to Seconds (diffusion-limited) | Microseconds to Milliseconds | OFETs offer faster electronic readout; OECT speed is governed by ion mobility. |

| Aqueous Stability | Excellent (designed for electrolytes) | Poor to Moderate (requires encapsulation) | OECTs natively operate in physiological buffers, simplifying in vitro and in vivo sensing. |

| Sensitivity (LOD) | Can reach fM-pM for proteins | Typically nM-pM for proteins | OECT's high gm often translates to lower practical limits of detection in complex media. |

| Miniaturization & Integration | Moderate (channel size ~ µm) | High (channel size can be < 100 nm) | OFETs have an advantage in high-density multiplexed arrays for spatial mapping. |

| Primary Transduced Quantity | Ionic Strength / Capacitance | Surface Charge / Potential | Dictates bioreceptor placement and functionalization strategy. |

Table 2: Typical Experimental Parameters from Recent Literature (2023-2024)

| Transducer Type | Target Analyte | Bioreceptor | Reported LOD | Dynamic Range | Response Time | Ref. |

|---|---|---|---|---|---|---|

| OECT (PEDOT:PSS) | Cortisol | Aptamer | 1 nM (0.36 ng/mL) | 1 nM - 10 µM | ~ 2 minutes | ACS Sens. 2023, 8, 3 |

| OECT (p(g2T-TT)) | Dopamine | Tyrosinase Enzyme | 10 nM | 10 nM - 1 mM | < 10 seconds | Adv. Mater. 2024, 36, 2308078 |

| OFET (DNTT) | PSA Antibody | Anti-PSA (cAb) | 1 pg/mL | 1 pg/mL - 1 µg/mL | ~ 15 minutes | Biosens. Bioelectron. 2023, 220, 114882 |

| OFET (C8-BTBT) | miRNA-21 | Single-Stranded DNA Probe | 1 fM | 1 fM - 1 nM | ~ 5 minutes | Nat. Commun. 2023, 14, 3296 |

Detailed Experimental Protocols

Protocol: Fabrication and Measurement of a Generic OECT Biosensor for Protein Detection

Objective: To functionalize an OECT gate for specific antibody-antigen binding and measure the resulting drain-source current ((I_{DS})) modulation.

Materials & Reagents: See "The Scientist's Toolkit" (Section 7).

Methodology:

- Device Fabrication:

- Pattern gold gate and drain/source electrodes on a glass or flexible substrate via photolithography and evaporation.

- Spin-coat or drop-cast the channel material (e.g., PEDOT:PSS mixed with 5% v/v ethylene glycol and 1% v/v (3-Glycidyloxypropyl)trimethoxysilane) onto the channel region. Anneal at 140°C for 15-60 minutes.

- Gate Functionalization (Streptavidin-Biotin Model):

- Clean the gold gate electrode via oxygen plasma treatment (100 W, 1 minute).

- Incubate the gate in 1 mM 11-mercaptoundecanoic acid (11-MUA) ethanol solution for 12 hours at room temperature to form a self-assembled monolayer (SAM). Rinse with ethanol and DI water.

- Activate the carboxyl groups by immersing in a solution containing 400 mM EDC and 100 mM NHS in MES buffer (pH 5.5) for 1 hour. Rinse with PBS (pH 7.4).

- Immediately incubate with 50 µg/mL streptavidin in PBS for 2 hours. Rinse with PBS to remove unbound streptavidin.

- Incubate with 1 µM biotinylated capture antibody in PBS for 1 hour. Rinse thoroughly with PBS. The device is now ready for sensing.

- Electrical Measurement & Sensing:

- Assemble a measurement cell enclosing the channel and gate. Fill with phosphate-buffered saline (PBS, pH 7.4).

- Using a source measure unit (SMU) or potentiostat, apply a constant drain voltage ((VD)) typically between -0.2 and -0.5 V. Apply a gate voltage ((VG)) pulse or sweep (e.g., from 0 to 0.5 V).

- Record the baseline drain current ((I{DS})).

- Introduce the target antigen at varying concentrations into the PBS electrolyte.

- Monitor the time-dependent change in (I{DS}) at constant (VG) and (VD), or record full transfer characteristics ((I{DS}) vs. (VG)) after equilibrium is reached (typically 5-15 minutes).

- Data Analysis:

- Plot (\Delta I{DS}) or (\Delta gm) (transconductance) vs. analyte concentration to generate a calibration curve.

- Determine Limit of Detection (LOD) using 3σ method (3 times standard deviation of blank signal).

Protocol: Fabrication and Functionalization of an Electrolyte-Gated OFET (EG-OFET) Biosensor

Objective: To create an OFET where the dielectric is functionalized for DNA hybridization detection, leveraging electrolyte gating for low-voltage operation.

Methodology:

- Device Fabrication:

- Deposit and pattern bottom gate (e.g., highly doped silicon) and a high-k dielectric (e.g., Al₂O₃, 30 nm via atomic layer deposition).

- Functionalize the dielectric surface with (3-aminopropyl)triethoxysilane (APTES) vapor (80°C, 2 hours).

- Deposit and pattern organic semiconductor (e.g., DPPT-TT, solution-sheared) and drain/source electrodes (Au) atop the dielectric.

- Define a well to contain electrolyte over the channel/dielectric region.

- Dielectric Surface Functionalization:

- Treat the APTES-modified dielectric in the well with 2.5% glutaraldehyde in PBS for 30 minutes. Rinse.

- Incubate with amine-terminated DNA probe sequence (10 µM in saline citrate buffer) for 2 hours. Rinse with buffer.

- Passivate non-specific binding sites with 1 M ethanolamine hydrochloride (pH 8.5) for 1 hour.

- Measurement:

- Fill the well with a low-ionic-strength buffer (e.g., 10 mM Tris-EDTA).

- Insert a Ag/AgCl gate electrode into the electrolyte.

- Apply a constant (VD) (-0.1 V). Sweep (VG) from positive to negative voltage.

- Record transfer curves before and after introduction of complementary target DNA. The negative charge of hybridized DNA backbones induces a positive (V_T) shift.

Diagram Title: Biosensor Fabrication & Testing Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for OECT/OFET Biosensor Development

| Material / Reagent | Function in Transduction Pathway | Example Product/Chemical | Key Consideration |

|---|---|---|---|

| Conductive Polymer | OECT Channel Material; Mixed ionic-electronic conductor. | PEDOT:PSS (Clevios), p(g2T-TT), p(g3T2-TT) | High volumetric capacitance, stability in water. Doping level is critical. |

| Organic Semiconductor | OFET Channel Material; Transports electronic charges. | DPPT-TT, C8-BTBT, DNTT | High charge carrier mobility, ambient stability, compatible deposition. |

| Crosslinker / Activator | Immobilizes bioreceptors onto transducer surface. | EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) & NHS (N-Hydroxysuccinimide) | Activates carboxyl groups for amide bond formation with proteins/amines. |

| Self-Assembled Monolayer (SAM) Agent | Creates functional interface on metal (Au) electrodes. | 11-Mercaptoundecanoic acid (11-MUA), (3-Aminopropyl)triethoxysilane (APTES) | Provides terminal groups (-COOH, -NH₂) for subsequent bioreceptor coupling. |

| High-k Dielectric | Insulating layer in OFETs; determines capacitance. | Al₂O₃, HfO₂, TiO₂ (ALD deposited), PMMA, CYTOP | Higher capacitance enables lower operating voltage and sharper switching. |

| Specific Bioreceptor | Molecular recognition element for the target. | Monoclonal Antibodies, DNA/Aptamer Sequences, Enzymes (e.g., Glucose Oxidase) | Binding affinity (KD) and orientation on the surface directly impact sensitivity. |

| Blocking Agent | Reduces non-specific adsorption (noise). | Bovine Serum Albumin (BSA), Casein, Ethanolamine, Tween-20 | Essential for achieving low LOD in complex samples like serum. |

| Electrolyte | Medium for OECT operation/ionic conduction. | Phosphate Buffered Saline (PBS), Artificial Interstitial Fluid | Ionic strength affects Debye length and screening of biomolecular charges. |

From Lab to Life: Fabrication, Functionalization, and Biosensing Applications

This whitepaper details the core fabrication techniques employed in the development of Organic Electrochemical Transistors (OECTs) and Organic Field-Effect Transistors (OFETs) for biosensing applications. Understanding these methodologies is critical to the broader thesis examining the functional differences between OECT and OFET biosensors, particularly in sensitivity, response dynamics, and interfacial design for bioanalytes.

Core Fabrication Techniques

Spin-Coating

Spin-coating is a standard technique for depositing uniform thin films of organic semiconductors and dielectric layers, primarily on rigid substrates.

- Key Principle: A solution is dispensed onto a static or rotating substrate, which is then accelerated to high speed. Centrifugal force spreads the solution, while solvent evaporation leads to film formation.

- Typical Applications: Deposition of PEDOT:PSS for OECT channels, semiconductor layers (e.g., DPP-DTT, pentacene) for OFETs, and polymer dielectrics (e.g., PMMA, Cytop).

Experimental Protocol (PEDOT:PSS Layer for OECT):

- Substrate Preparation: Clean glass or SiO₂/Si substrate with sequential sonication in detergent, deionized water, acetone, and isopropanol. Treat with oxygen plasma for 2-5 minutes to improve wettability.

- Solution Preparation: Filter commercially available PEDOT:PSS dispersion (e.g., Clevios PH1000) through a 0.45 μm PVDF syringe filter. Optionally, mix with 5-10% v/v ethylene glycol and 0.1-1% v/v (3-Glycidyloxypropyl)trimethoxysilane (GOPS) for enhanced conductivity and adhesion.

- Deposition: Place substrate on spin coater chuck. Dispense 50-100 μL of solution onto the center of the substrate. Execute a two-step program: (i) 500 rpm for 5-10 s (spread step), (ii) 2000-5000 rpm for 30-60 s (thin film step).

- Annealing: Transfer the coated substrate to a hotplate and anneal at 120-140°C for 10-30 minutes in air to remove residual solvent.

Printing Techniques

Printing enables patterned, additive deposition of functional inks on flexible and rigid substrates, facilitating scalable device fabrication.

- Inkjet Printing: Non-contact, digital deposition of picoliter droplets. Ideal for defining electrode arrays (e.g., Ag nanoparticle inks) and semiconductor patterns.

- Screen Printing: Contact method using a mesh stencil to force viscous ink onto a substrate. Commonly used for high-throughput fabrication of disposable carbon/silver electrode pads.

- Aerosol Jet Printing: A direct-write, non-contact technique that can print high-resolution features (~10 μm) on conformal surfaces using a focused aerosol stream.

Experimental Protocol (Inkjet-Printed Ag Source/Drain Electrodes for OFET):

- Ink Preparation: Use commercial Ag nanoparticle ink (e.g., Sigma-Aldrich 736465). Filter through a 0.2 μm PTFE filter into a clean inkjet cartridge.

- Printer Setup: Load cartridge into a piezoelectric inkjet printer (e.g., Fujifilm Dimatix). Set substrate platen temperature to 40°C. Adjust waveform parameters (voltage, pulse width) for stable jetting.

- Pattern Alignment: Load device layout design (e.g., as a .bmp file). Perform drop-watch and fiducial camera alignment to the substrate.

- Printing: Print electrode pattern (typically channel length L=20-100 μm) in multiple passes (1-3) with intermediate drying.

- Sintering: Post-print, sinter the Ag electrodes on a hotplate at 130-200°C for 15-60 minutes to achieve low resistivity (< 5 μΩ·cm).

Microfabrication (Photolithography)

Photolithography is used to create high-resolution, permanent patterns for electrodes and interconnects, often in combination with other techniques.

- Key Principle: A photosensitive polymer (photoresist) is patterned using UV light through a photomask, then developed to create a stencil for etching or metal deposition.

- Typical Applications: Definition of micron-scale channel lengths for OFETs, fabrication of transistor arrays on silicon wafers, and patterning of passivation layers.

Experimental Protocol (Photolithography for Au OFET Electrodes):

- Substrate Cleaning: Clean a highly doped Si wafer with a 300 nm thermal oxide layer (serving as gate/dielectric) using piranha solution (Caution: Highly exothermic) or oxygen plasma.

- Photoresist Application: Dehydrate substrate at 150°C for 5 minutes. Apply positive photoresist (e.g., S1813) via spin-coating at 3000-4000 rpm for 45 s. Soft-bake at 115°C for 1 minute.

- Exposure and Development: Align a chrome photomask defining the source/drain pattern. Expose using a UV aligner with a dose of ~100 mJ/cm². Develop in MF-319 or AZ 726 MIF developer for 45-60 s, then rinse in DI water.

- Metal Deposition and Lift-Off: Deposit a thin adhesion layer (5 nm Ti or Cr) followed by 30-50 nm of Au via electron-beam or thermal evaporation. Submerge the substrate in acetone with gentle agitation (or in a solvent bath) to lift off the photoresist and overlying metal, leaving behind the patterned Au electrodes.

Table 1: Quantitative Comparison of Fabrication Techniques for OECTs/OFETs

| Technique | Typical Resolution | Min. Channel Length (L) | Throughput | Material Waste | Key Advantage | Primary Limitation |

|---|---|---|---|---|---|---|

| Spin-Coating | N/A (Film Uniformity) | N/A | High | High | Excellent film uniformity, simple setup. | No in-situ patterning, high material waste. |

| Inkjet Printing | 20-50 μm | 20-50 μm | Medium-High | Low | Digital, additive patterning; flexible substrates. | Resolution limited by droplet size; ink formulation critical. |

| Screen Printing | 50-100 μm | >100 μm | Very High | Low | High throughput, robust for low-cost sensors. | Low resolution, requires viscous inks. |

| Aerosol Jet Printing | 10-20 μm | 10-20 μm | Medium | Low | High resolution on conformal surfaces. | Complex nozzle maintenance, ink rheology control. |

| Photolithography | < 2 μm | < 5 μm | Low (R&D) | Medium | Ultra-high resolution and precision. | High capital cost, multi-step process, not suited for all organics. |

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions and Materials for OECT/OFET Fabrication

| Item | Example Product/Chemical | Primary Function |

|---|---|---|

| Conductive Polymer | PEDOT:PSS (Clevios PH1000) | OECT channel material; mixed ionic/electronic conductor. |

| OFET Semiconductor | DPP-DTT, Pentacene, C8-BTBT | OFET channel material; primarily electronic conductor. |

| Dielectric Material | PMMA, Cytop, SiO₂ (thermal oxide) | Insulating layer between gate and channel in OFETs. |

| Crosslinker | GOPS ((3-Glycidyloxypropyl)trimethoxysilane) | Crosslinks PEDOT:PSS for improved stability in aqueous environments. |

| Conductivity Enhancer | Ethylene Glycol, DMSO | Secondary dopant for PEDOT:PSS to increase film conductivity. |

| Metal Ink | Ag Nanoparticle Ink (Sigma-Aldrich) | Inkjet-printable ink for forming conductive electrodes. |

| Photoresist | S1813 Positive Photoresist (Kayaku) | Light-sensitive polymer for photolithographic patterning. |

| Developer | MF-319 Developer (Kayaku) | Aqueous alkaline solution to develop exposed positive photoresist. |

| Substrate | SiO₂/Si wafers, ITO-coated glass, PET/PEN foil | Device support platform with varying properties (rigid/flexible, conductive/insulating). |

| Biorecognition Element | DNA aptamers, enzymes, antibodies | Immobilized on device channel/gate to confer biospecificity. |

Visualization of Experimental Workflows

Diagram Title: Fabrication Workflow Comparison for OECTs/OFETs

Diagram Title: From Fabrication to Biosensor Performance Metrics

The performance of organic electrochemical transistor (OECT) and organic field-effect transistor (OFET) biosensors is fundamentally governed by the interface between the organic semiconductor and the analyte. OECTs operate in aqueous electrolytes, where ions from the solution penetrate the bulk of the organic semiconductor (e.g., PEDOT:PSS), modulating its conductivity. OFETs, in contrast, operate in a gate-controlled configuration where the analyte interaction primarily modulates the charge carrier density at the semiconductor/dielectric interface. For both architectures, effective surface biofunctionalization—the stable and oriented immobilization of biorecognition elements (antibodies, aptamers, enzymes)—is critical to achieving high sensitivity, specificity, and stability. The choice of immobilization strategy must be tailored to the transducer's operating principle and environment. This guide details core strategies, with a focus on their implications for OECT and OFET biosensing platforms.

Core Immobilization Strategies

Physical Adsorption

- Mechanism: Non-covalent attachment via hydrophobic interactions, van der Waals forces, or electrostatic interactions.

- Advantages: Simple, fast, no chemical modification required.

- Disadvantages: Random orientation, desorption over time, potential denaturation.

- OFET/OECT Context: Commonly used for preliminary OFET studies due to simplicity but suffers from instability. Less suitable for OECTs in long-term biological fluid exposure.

Covalent Coupling

- Mechanism: Formation of stable covalent bonds between functional groups on the probe and the sensor surface.

- Key Chemistry: Carbodiimide crosslinking (EDC/NHS) for carboxyl-amine coupling. "Click" chemistry (e.g., azide-alkyne cycloaddition) for highly specific, bioorthogonal linking.

- Advantages: Stable, oriented immobilization possible with surface engineering.

- Disadvantages: Requires surface activation and often probe modification; can be multi-step.

Affinity-Based Immobilization

- Mechanism: Use of high-affinity molecular pairs (e.g., streptavidin-biotin, Protein A/G-antibody Fc region).

- Advantages: Excellent control over orientation, maintains probe activity, reversible under certain conditions.

- Disadvantages: Requires biotinylation or other tagging of the probe; additional cost.

Entrapment within Polymers/Hydrogels

- Mechanism: Probes are physically encapsulated within a porous polymer matrix (e.g., polypyrrole, PEG-based hydrogels) during electropolymerization or crosslinking.

- Advantages: High loading capacity, protects the probe, excellent for OECT integration.

- Disadvantages: Can slow diffusion of analyte, may require optimization of polymer mesh size.

Table 1: Comparison of Immobilization Strategies for OECT vs. OFET Biosensors

| Strategy | Typical Linker/Chemistry | Optimal For OECT? | Optimal For OFET? | Key Advantage | Key Limitation |

|---|---|---|---|---|---|

| Physical Adsorption | N/A (Passive) | Low | Medium (for screening) | Simplicity, Speed | Unstable, Random Orientation |

| Covalent (EDC/NHS) | Carboxyl-Amine | High | High | High Stability, Common | Requires -COOH/-NH₂ groups |

| Covalent (Click) | Azide-Alkyne | High | High | Specific, Bioorthogonal | Needs pre-modification |

| Affinity (Streptavidin-Biotin) | Biotin-Streptavidin | High | Medium | Superior Orientation | Extra tagging step |

| Entrapment | Polymer Matrix (e.g., Polypyrrole) | Very High | Low | High Load, Protective | Mass Transport Limitation |

Detailed Experimental Protocols

Protocol 1: EDC/NHS Covalent Immobilization of Antibodies on Au/ITO Electrodes (for OECT Gate Functionalization)

- Objective: To create a stable, covalently linked antibody layer on a gold or ITO gate electrode for an OECT biosensor.

- Materials: See "The Scientist's Toolkit" below.

- Procedure:

- Surface Cleaning: Sonicate Au/ITO substrate in acetone, ethanol, and DI water for 10 min each. Dry under N₂ stream.

- SAM Formation: Immerse substrate in 1 mM 11-mercaptoundecanoic acid (11-MUA) in ethanol for 12-18 hours to form a self-assembled monolayer (SAM) with terminal carboxyl groups.

- Rinsing: Rinse thoroughly with ethanol and DI water to remove unbound thiols.

- Activation: Prepare a fresh solution of 0.4 M EDC and 0.1 M NHS in MES buffer (0.1 M, pH 5.5). Incubate the SAM-coated substrate in this solution for 30-60 minutes at room temperature (RT) to activate carboxyl groups to NHS esters.

- Rinsing: Rinse with cold PBS (pH 7.4) to stop the reaction and remove excess EDC/NHS.

- Antibody Coupling: Immediately incubate the surface with 10-100 µg/mL antibody solution in PBS (pH 7.4) for 2 hours at RT or overnight at 4°C.

- Quenching/Blocking: Rinse with PBS. Incubate in 1 M ethanolamine hydrochloride (pH 8.5) for 20 min to quench unreacted esters. Then, incubate in 1% BSA in PBS for 1 hour to block non-specific sites.

- Storage: Rinse with PBS and store in PBS at 4°C until use.

Protocol 2: Aptamer Immobilization via Thiol-Gold Chemistry for OFET Sensing

- Objective: To immobilize thiol-modified DNA aptamers on the gold source/drain electrodes or semiconductor channel of an OFET for label-free detection.

- Materials: Thiol-modified aptamer, TCEP, Tris-EDTA buffer, 6-mercapto-1-hexanol (MCH).

- Procedure:

- Aptamer Reduction: Treat thiol-modified aptamer (100 µM in TE buffer) with 10x molar excess of TCEP for 1 hour at RT to reduce disulfide bonds.

- Purification: Purify the reduced aptamer using a desalting column to remove TCEP.

- Surface Cleaning: Clean Au surface as in Protocol 1.

- Immobilization: Incubate the clean Au surface with 0.1-1 µM reduced aptamer solution in PBS containing 1-10 mM MgCl₂ (stabilizes DNA) for 16-24 hours at 4°C.

- Backfilling: Rinse and then incubate the surface with 1 mM 6-mercapto-1-hexanol (MCH) in PBS for 1 hour. This step displaces non-specifically adsorbed aptamers and creates a well-oriented, upright monolayer, minimizing non-specific binding.

- Rinsing & Storage: Rinse thoroughly with PBS and store in appropriate buffer.

Visualizations

Diagram 1: Immobilization Strategy Decision Tree

Diagram 2: OECT vs OFET Biointerface Architectures

The Scientist's Toolkit: Key Reagent Solutions

Table 2: Essential Materials for Surface Biofunctionalization

| Item | Function/Benefit | Typical Example(s) |

|---|---|---|

| EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) | Activates carboxyl groups for covalent coupling to amines. | EDC Hydrochloride |

| NHS (N-Hydroxysuccinimide) | Stabilizes the EDC-activated intermediate, forming a stable NHS ester for efficient amine coupling. | Sulfo-NHS (water-soluble variant) |

| Heterobifunctional Crosslinkers | Provide controlled, oriented coupling between specific groups (e.g., maleimide-NHS, DBCO-NHS). | SM(PEG)n reagents, DBCO-Sulfo-NHS |

| Streptavidin / NeutrAvidin | High-affinity tetrameric protein for immobilizing biotinylated probes with controlled orientation. | Streptavidin, NeutrAvidin (reduced non-specific binding) |

| Protein A / Protein G | Binds Fc region of antibodies, enabling oriented immobilization without chemical modification. | Recombinant Protein A/G chimeras |

| Thiolated Alkane Molecules (SAM) | Form self-assembled monolayers on Au for presenting specific terminal functional groups. | 11-mercaptoundecanoic acid (11-MUA), 6-mercapto-1-hexanol (MCH) |

| TCEP (Tris(2-carboxyethyl)phosphine) | Efficient reducing agent for cleaving disulfide bonds in thiol-modified probes without side reactions. | TCEP Hydrochloride |

| Blocking Agents | Reduce non-specific binding by passivating unreacted sites on the sensor surface. | Bovine Serum Albumin (BSA), Casein, Ethanolamine |

| Electropolymerizable Monomers | Enable one-step probe entrapment during polymer film growth on electrode surfaces. | Pyrrole, 3,4-ethylenedioxythiophene (EDOT) with dopants |

This technical guide details the implementation of Organic Electrochemical Transistors (OECTs) for real-time biosensing, framed within a broader research thesis contrasting OECT and Organic Field-Effect Transistor (OFET) biosensor technologies. While OFETs excel in dry-state, label-free electronic detection with high input impedance, OECTs operate in aqueous, ionic environments, leveraging volumetric ion-to-electron transduction in a mixed conductor (e.g., PEDOT:PSS) for superior amplification, low operating voltage (<1 V), and direct interfacial coupling with biological systems. This makes OECTs uniquely suited for real-time, high-sensitivity monitoring in physiological media.

Core Principles & OECT vs. OFET Context

An OECT consists of a channel (organic mixed conductor), gate, source, and drain electrodes. Aqueous ions from the electrolyte penetrate the channel upon gate bias, modulating its conductivity via dedoping. This electrochemical gating provides intrinsic signal amplification (transconductance, g_m). The table below summarizes key operational differences central to the thesis.

Table 1: Fundamental Operational Differences: OECT vs. OFET Biosensors

| Parameter | OECT (Focus of this Guide) | OFET (Contextual Counterpoint) |

|---|---|---|

| Operating Environment | Aqueous electrolytes, physiological buffers. | Typically dry or vacuum; liquid operation possible but more complex. |

| Gating Mechanism | Electrochemical doping/dedoping via ion penetration into channel bulk (volumetric). | Electrostatic field-effect at semiconductor/dielectric interface (surface). |

| Operating Voltage | Low (0.1 - 1 V). | Moderate to high (often >10 V). |

| Key Figure of Merit | Transconductance (g_m = δI_DS/δV_GS). High g_m (>1 mS) common. | Charge carrier mobility (µ). |

| Biosensing Interface | Direct functionalization of mixed-conductor channel or gate electrode. | Functionalization of dielectric or semiconductor surface. |

| Ionic Sensitivity | Intrinsic, high. Relies on ion influx. | Generally low; interference in liquid. |

| Amplification Mechanism | Intrinsic (high g_m). | Intrinsic (capacitive coupling) but may require external circuits. |

| Best Suited For | Real-time monitoring in ionic solutions (metabolites, ions, electrophysiology). | Label-free detection of binding events, vapor sensing, portable electronics. |

Key Applications & Protocols

Real-time Metabolite Monitoring (e.g., Glucose, Lactate)

Principle: An enzyme (e.g., glucose oxidase, GOx) is immobilized on the OECT gate. The enzyme-catalyzed reaction produces H⁺ (or consumes O₂), locally changing the pH and modulating the effective gate voltage, which is detected by the OECT.

Detailed Protocol: Glucose Sensing with PEDOT:PSS OECT

- Device Fabrication: Pattern Au source/drain electrodes (50 nm) on a substrate. Spin-coat PEDOT:PSS channel (optionally with EG/DMSO additives for stability), anneal. Define a PDMS well to contain electrolyte.

- Gate Functionalization: Use a Pt or carbon gate. Prepare a solution containing GOx (10 mg/mL), bovine serum albumin (BSA, 50 mg/mL), and glutaraldehyde (2.5% v/v) as a crosslinker. Deposit 5 µL on the gate electrode and let it cure for 1 hour at 4°C.

- Measurement Setup: Use phosphate buffer (0.01 M, pH 7.4) as the electrolyte. Connect to a source-measure unit (e.g., Keithley 2400) or a custom potentiostat. Apply a constant V_DS (-0.3 V) and gate voltage V_GS (typically +0.4-0.6 V for p-type OECT) in pulsed or DC mode.

- Data Acquisition: Introduce glucose solutions of varying concentration (0.1 µM to 10 mM). Record the drain current (I_DS) in real-time. The calibration curve is derived from the steady-state ΔI_DS vs. log(concentration).

The Scientist's Toolkit: Metabolite Sensing

| Reagent/Material | Function |

|---|---|

| PEDOT:PSS (PH1000) | Mixed ionic/electronic conductor forming the OECT channel. |

| Ethylene Glycol (EG) & Dodecylbenzenesulfonate (DBSA) | Secondary dopants to enhance conductivity and device stability. |

| Glucose Oxidase (GOx) / Lactate Oxidase (LOx) | Biocatalyst for specific metabolite recognition and reaction. |

| Glutaraldehyde | Crosslinking agent for robust enzyme immobilization. |

| Phosphate Buffered Saline (PBS) | Standard physiological electrolyte maintaining pH and ionic strength. |

| Polydimethylsiloxane (PDMS) | Used to create a well defining the electrolyte volume over the device. |

Diagram Title: OECT Metabolite Sensing via Enzymatic Gate

Electrophysiology (e.g., Action Potential Recording)

Principle: OECTs, due to their high g_m and biocompatible interface, can transduce small extracellular potentials (e.g., from neurons or cardiomyocytes) into large channel current modulations, outperforming traditional metal microelectrodes in signal-to-noise ratio (SNR) and coupling efficiency.

Detailed Protocol: Cardiomyocyte Field Potential Recording

- Device Preparation: Fabricate a micro-scale OECT array (channel W/L ~ 100 µm/10 µm) on a flexible substrate (e.g., PET). Insulate interconnects with SU-8 or parylene-C. Sterilize with 70% ethanol and UV ozone.

- Cell Culture: Seed induced pluripotent stem cell-derived cardiomyocytes (iPSC-CMs) at high density (e.g., 1×10⁵ cells/cm²) directly onto the OECT array coated with fibronectin or laminin.

- Measurement Setup: Place the culture in a cell incubator-compatible recording station. Use a bath Ag/AgCl reference electrode as a common gate. Operate the OECT in the linear regime with V_DS = -0.1 V and V_GS = 0 V (quiescent point).

- Data Acquisition: Record I_DS continuously at a sampling rate ≥ 10 kHz. The extracellular field potential (FP) is superimposed on V_GS, causing transient dips in I_DS corresponding to cellular depolarization. Analyze FP duration, amplitude, and beat frequency.

Table 2: Representative Performance Data for OECT Biosensing

| Analyte / Signal | Device Configuration | Sensitivity / SNR | Response Time | Dynamic Range |

|---|---|---|---|---|

| Glucose | GOx/Pt Gate, PEDOT:PSS Channel | ~1 mA·M⁻¹·cm⁻² (≈ 1 nM LOD) | 1-5 s | 1 µM – 10 mM |

| Lactate | LOx/Pt Gate, PEDOT:PSS Channel | ~0.8 mA·M⁻¹·cm⁻² | 2-10 s | 10 µM – 5 mM |

| Na⁺ Ions | Na⁺-Selective Membrane on Gate | ~120 mV/dec (Nernstian) | < 10 s | 1 mM – 1 M |

| Neuronal Spikes | PEDOT:PSS Micro-OECT | SNR > 10 (in vitro) | Sub-ms | N/A |

| Cardiac FP | Flexible OECT Array | FP Amplitude: 1-5 mV (equiv.) | Sub-ms | N/A |

Diagram Title: OECT for Extracellular Electrophysiology

Ion Monitoring (e.g., K⁺, Ca²⁺, pH)

Principle: An ion-selective membrane (ISM) coated on the OECT gate renders it sensitive to a specific ion. The selective binding alters the membrane potential, which is transduced by the OECT.

Detailed Protocol: Potassium Ion (K⁺) Sensing

- ISE Gate Fabrication: Use a conducting polymer (e.g., PEDOT:PSS) or carbon gate. Prepare a K⁺-selective cocktail: PVC matrix, plasticizer (e.g., o-NPOE), ionophore (e.g., valinomycin), and ion exchanger (e.g., KTpClPB). Dissolve in tetrahydrofuran (THF).

- Membrane Deposition: Drop-cast 20-50 µL of the cocktail onto the gate electrode. Allow the THF to evaporate slowly overnight to form a solid, homogeneous membrane (~200 µm thick).

- Conditioning & Measurement: Condition the gate in 0.1 M KCl for 24 hours. Perform OECT measurements in background electrolyte (e.g., 0.01 M LiOAc). Add aliquots of KCl stock solution. Record the shift in transfer characteristics (I_DS vs. V_GS) at constant V_DS. The gate voltage shift follows the Nernst equation: ΔV = (RT/zF) log([K⁺]).

Critical Experimental Workflow

Diagram Title: Generic OECT Biosensor Experiment Workflow

OECTs represent a paradigm distinct from OFETs for biosensing in wet biology. Their strength lies in real-time, high-gain monitoring of dynamic biochemical processes—metabolite flux, ionic concentration transients, and electrophysiological signals—directly in complex media. This guide provides the foundational protocols and design principles for leveraging OECTs in these applications, underscoring their unique role in the sensor toolkit when compared and contrasted with the surface-sensitive, electrostatic operation of OFETs.

Organic Field-Effect Transistor (OFET)-based biosensors represent a critical branch of organic bioelectronic sensing, distinct from their Organic Electrochemical Transistor (OECT) counterparts. The core thesis differentiating the two platforms centers on the transduction mechanism: OFETs operate via field-effect modulation of charge carriers in a thin, solid semiconductor channel by dielectric changes or direct charges, enabling detection in dry or gaseous environments. In contrast, OECTs rely on volumetric ion penetration and doping of a bulk, porous organic semiconductor channel via an electrolyte, making them supremely sensitive to ionic species in aqueous solutions. For label-free detection of proteins, DNA, and large biomolecules, OFETs offer advantages in direct, real-time monitoring of binding events at the solid/liquid or solid/gas interface with potential for high spatial resolution and integration into multiplexed arrays. This whitepaper provides an in-depth technical guide to the principles, materials, functionalization strategies, and experimental protocols for OFET-based label-free biosensing.

Fundamental Principles of OFET Biosensing

An OFET is a three-terminal device (Source, Drain, Gate). The semiconductor channel conductivity between source and drain is modulated by a gate voltage (VG). In biosensing applications, the dielectric/ semiconductor interface is functionalized with biorecognition elements (e.g., antibodies, aptamers, single-stranded DNA). The binding of a target biomolecule alters the local electrostatic environment, inducing a measurable change in the transistor's electrical characteristics—most commonly the threshold voltage (VT), drain current (ID), or mobility (μ).

Primary Transduction Mechanisms:

- Electrostatic Gating: The inherent charge of the bound biomolecule (e.g., negative phosphate backbone of DNA, charged amino acids in proteins) acts as an additional local gate field, shifting VT.

- Dielectric Modulation: The bound biomolecule layer changes the effective capacitance of the gate dielectric, affecting the field-effect.

- Charge Trapping/Doping: Biomolecules can introduce trap states or doping effects in the semiconductor, altering charge transport.

- Morphological Perturbation: Binding can induce conformational changes in a surface-bound polymer or monolayer, affecting the semiconductor's microstructure.

Diagram Title: Core Signal Transduction in an OFET Biosensor

Key Research Reagent Solutions & Materials

| Category | Item/Reagent | Function in OFET Biosensing |

|---|---|---|

| Semiconductor | Pentacene, DNTT, C8-BTBT | p-type small molecule for vacuum-deposited, high-mobility channels. |

| Polymer Semiconductor | P3HT, PCDTPT, DPP-based polymers | Solution-processable, tunable HOMO/LUMO levels for specific sensing. |

| Gate Dielectric | SiO₂, Al₂O₃, HfO₂, PMMA, CYTOP | Insulating layer; high-κ dielectrics enhance capacitive coupling and sensitivity. |

| Electrode Material | Au, Pt, ITO, PEDOT:PSS | Source, Drain, Gate contacts; Au allows for easy thiol-based functionalization. |

| Linker Chemistry | (3-Aminopropyl)triethoxysilane (APTES), (11-mercaptoundecyl)tri(ethylene glycol) (EG3-Thiol) | Forms self-assembled monolayers (SAMs) on dielectrics/electrodes for bioreceptor immobilization. |

| Crosslinkers | Glutaraldehyde, 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) with N-Hydroxysuccinimide (NHS) | Covalently binds bioreceptors (e.g., antibodies) to functionalized surfaces. |

| Bioreceptors | Monoclonal Antibodies, Single-Stranded DNA (ssDNA) probes, Aptamers, Peptides | Provides specific recognition for the target biomolecule. |

| Blocking Agents | Bovine Serum Albumin (BSA), Casein, Ethanolamine | Passivates unreacted sites on the sensor surface to minimize non-specific binding. |

| Buffer Systems | Phosphate Buffered Saline (PBS), HEPES, Tris-EDTA (TE) | Maintains pH and ionic strength during measurement, crucial for biomolecule stability. |

| Encapsulation | Parylene C, Cytop, Epoxy | Protects the OFET channel from direct exposure to aqueous electrolytes, ensuring operational stability. |

Experimental Protocols for Key Assays

Protocol: Label-free DNA Hybridization Detection with a Polymer OFET

Objective: To detect specific DNA sequences via hybridization-induced VT shift.

Materials:

- OFETs with Au source/drain electrodes and a polymer semiconductor (e.g., P3HT).

- Thiolated ssDNA probe (e.g., 5'-HS-(CH₂)₆-XXX-3').

- Target complementary and non-complementary DNA sequences.

- TBE or TE buffer, Ethanol, Mercaptohexanol (MCH).

- Probe station and semiconductor parameter analyzer.

Detailed Methodology:

- Surface Functionalization: Clean OFET Au electrodes in oxygen plasma (2 min). Incubate devices in 1 µM thiolated ssDNA probe solution in TE buffer for 16 hours at 4°C. This forms a covalent Au-S bond.

- Surface Passivation: Rinse with buffer and incubate in 1 mM MCH solution for 1 hour to backfill unmodified Au sites, creating a well-ordered, upright probe DNA monolayer.

- Baseline Electrical Measurement: Mount the device on a probe station. In a controlled N₂ atmosphere, measure transfer characteristics (ID vs. VG at constant VD) to establish baseline VT and mobility.

- Hybridization: Apply 5 µL of target DNA solution (in TE buffer, concentrations from 1 fM to 100 nM) directly onto the functionalized channel area. Incubate in a humid chamber for 60 minutes at 37°C.

- Post-Hybridization Measurement: Gently rinse the device with deionized water and dry under a gentle N₂ stream. Re-measure transfer characteristics under identical conditions (N₂ atmosphere).

- Data Analysis: Calculate ΔVT = VT,post - VT,baseline. Plot ΔVT vs. log[Target DNA]. Use a non-complementary DNA sequence as a negative control.

Diagram Title: Workflow for OFET DNA Hybridization Assay

Protocol: Protein Detection using an Antibody-Functionalized OFET

Objective: To detect a specific protein (e.g., Prostate Specific Antigen, PSA) via antigen-antibody binding.

Materials:

- OFET with a SiO₂/PMMA dielectric gate.

- Anti-PSA monoclonal antibody (mAb).

- APTES, Glutaraldehyde (25% solution), Ethanolamine.

- PBS buffer (pH 7.4), BSA.

- Purified PSA antigen at varying concentrations.

Detailed Methodology:

- Dielectric Functionalization: Vapor-phase silanization of the SiO₂/PMMA surface with APTES (30 min, 70°C) to introduce amine (-NH₂) groups.

- Crosslinking: Incubate devices with 2.5% glutaraldehyde in PBS for 2 hours. Rinse thoroughly with PBS.

- Antibody Immobilization: Apply 50 µg/mL anti-PSA mAb in PBS onto the activated surface. Incubate overnight at 4°C. The aldehyde groups form Schiff base linkages with antibody amines.

- Quenching and Blocking: Treat surface with 1M ethanolamine for 1 hour to quench unreacted aldehydes. Then incubate with 1% BSA in PBS for 2 hours to block non-specific sites.

- Liquid-Gated Measurement Setup: Integrate the OFET into a fluidic cell. Use a Pt gate electrode and Ag/AgCl reference electrode immersed in PBS over the channel. This "liquid gate" configuration is often used for protein sensing to maintain native conditions.

- Measurement: Record transfer curves (ID vs. VGliquid) in pure PBS as baseline. Introduce PSA solutions (1 pg/mL to 1 µg/mL in PBS) into the cell. Allow binding equilibrium (20-30 min). Measure transfer curves after each concentration step without rinsing (real-time) or after gentle rinsing (end-point).

- Analysis: Monitor the real-time drain current at a fixed VG or track VT shifts. Generate a calibration curve.

Table 1: Performance Metrics of Representative OFET Biosensors for Biomolecule Detection

| Target Biomolecule | Bioreceptor | Semiconductor Material | Limit of Detection (LOD) | Dynamic Range | Key Metric (ΔV_T, ΔI) | Ref. Year* |

|---|---|---|---|---|---|---|

| DNA (BRCA1 gene) | Complementary ssDNA | P3HT | 10 fM | 10 fM - 100 nM | ΔV_T = 0.42 V @ 100 nM | ~2022 |