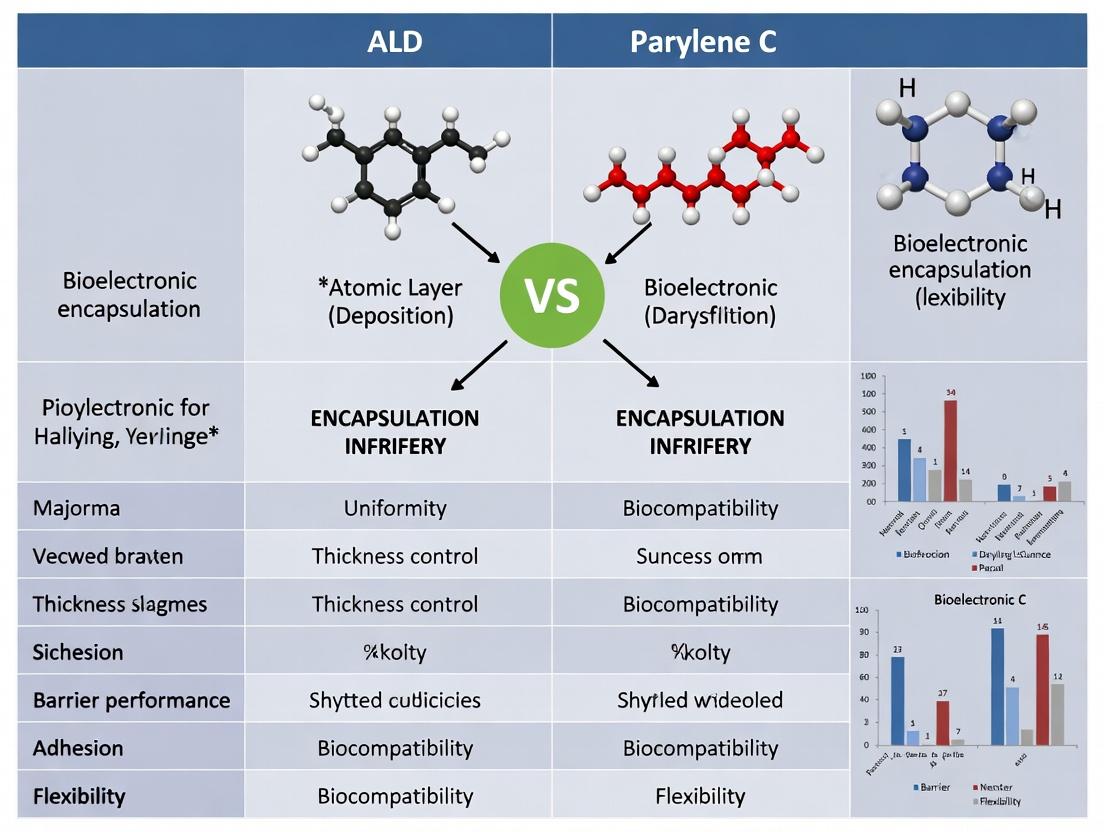

ALD vs Parylene C: The Ultimate Showdown for Bioelectronic Encapsulation in Medical Implants

This comprehensive analysis compares Atomic Layer Deposition (ALD) and Parylene C thin-film coatings for bioelectronic encapsulation, targeting researchers and biomedical engineers.

ALD vs Parylene C: The Ultimate Showdown for Bioelectronic Encapsulation in Medical Implants

Abstract

This comprehensive analysis compares Atomic Layer Deposition (ALD) and Parylene C thin-film coatings for bioelectronic encapsulation, targeting researchers and biomedical engineers. We explore the fundamental chemistry and failure modes of each, detail state-of-the-art deposition methodologies, address critical reliability and optimization challenges, and provide a direct, quantitative comparison of barrier properties, biocompatibility, and performance in vivo. The review synthesizes the latest research to guide the selection of encapsulation strategies for next-generation neural interfaces, drug-delivery devices, and chronic implants.

The Core Challenge: Understanding Moisture Barrier Fundamentals for Long-Term Implant Survival

The long-term reliability of implantable bioelectronics is fundamentally compromised by the body's hostile environment. Moisture, ions, and reactive biomolecules penetrate imperfect barriers, leading to device failure. This comparison guide evaluates two leading encapsulation technologies—Atomic Layer Deposition (ALD) and Parylene C—within the critical context of achieving hermetic, long-term stability.

Performance Comparison: ALD vs. Parylene C

The following table summarizes key metrics from recent in vitro and in vivo studies, comparing ALD (exemplified by Al₂O₃ and HfO₂) and Parylene C.

Table 1: Encapsulation Performance Comparison for Bioelectronic Interfaces

| Metric | ALD (Al₂O₃/HfO₂) | Parylene C (Standard) | Test Method & Conditions |

|---|---|---|---|

| Water Vapor Transmission Rate (WVTR) | < 10⁻⁶ g/m²/day (for 100 nm bilayer) | 0.2 - 0.5 g/m²/day (25 µm thick) | MOCON test, 37°C, 100% RH |

| Effective Lifetime in Saline (37°C) | > 5 years (projected for 200 nm) | 30 - 180 days (for 5-10 µm) | Electrochemical impedance spectroscopy (EIS) of metal traces |

| Conformality / Step Coverage | Excellent (uniform on high-aspect-ratio 3D structures) | Good (pin-hole risk at sharp edges) | SEM imaging of coated microelectrode arrays |

| Biocompatibility (ISO 10993) | Excellent (for Al₂O₃, HfO₂) | Excellent | In vivo implantation, histological analysis |

| Mechanical Flexibility | Poor (ceramic, brittle) | Excellent (polymer, conformal) | Bending test to failure |

| Dielectric Constant (εᵣ) | ~9 (Al₂O₃), ~25 (HfO₂) | ~3.15 | Capacitance-Voltage measurement |

| Process Temperature | 80°C - 200°C | Ambient (post-deposition) | - |

| Thickness for Effective Barrier | 20 - 100 nm (multi-layer) | 5 - 20 µm | Failure analysis via leakage current |

Experimental Protocols for Barrier Performance Evaluation

Calcium Layer Test for Hermeticity

Purpose: To visually and quantitatively assess the WVTR of thin-film barriers. Protocol:

- Substrate Preparation: Pattern a 100 nm thick calcium (Ca) layer on a silicon or glass substrate.

- Encapsulation: Coat the Ca-patterned substrate with the test barrier (ALD or Parylene C) using standard deposition parameters.

- Accelerated Aging: Expose the sample to phosphate-buffered saline (PBS) at 60°C or 85°C.

- Data Acquisition: Use optical microscopy to monitor the opaque metallic Ca squares over time. Hydrolysis converts Ca to transparent Ca(OH)₂.

- Analysis: Calculate the WVTR using the time-to-transition of the squares and known Ca layer geometry.

Electrochemical Impedance Spectroscopy (EIS) forIn VitroLifetime

Purpose: To predict in vivo encapsulation failure by tracking moisture ingress. Protocol:

- Test Structure Fabrication: Fabricate interdigitated electrode (IDE) arrays with trace widths/spacing of 10-50 µm.

- Encapsulation: Apply the barrier coating (ALD, Parylene C, or bilayer) to the IDE.

- Immersion Testing: Immerse the coated IDE in 0.9% NaCl solution at 37°C or 57°C (accelerated).

- Periodic Measurement: Measure impedance magnitude at 1 kHz (a sensitive frequency for corrosion detection) at regular intervals.

- Failure Criterion: Define failure as a 20% drop in impedance magnitude from the initial dry-state value, indicating a conductive pathway from fluid ingress.

Diagram: Experimental Workflow for Barrier Evaluation

Title: Barrier Evaluation Workflow

Diagram: Moisture Ingress Leading to Device Failure

Title: Failure Pathway from Barrier Defect

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Encapsulation Research

| Item | Function in Research | Example / Specification |

|---|---|---|

| Interdigitated Electrode (IDE) Chips | Standardized test structure for quantitative EIS-based lifetime studies. | Custom-fabricated Au or Pt electrodes on SiO₂/Si; 10 µm line/space. |

| Calcium-coated Test Slides | Pre-patterned substrates for direct, visual WVTR measurement per ASTM F1249. | 100 nm Ca layer in 1 cm² squares under a protective lid. |

| Phosphate-Buffered Saline (PBS) | Standard in vitro aging medium simulating ionic body fluid. | 1X, pH 7.4, 0.0067 M PO₄³⁻, sterile-filtered. |

| ALD Precursors (TMA, TDMAH) | High-purity sources for depositing consistent Al₂O₃ or HfO₂ barrier films. | Trimethylaluminum (TMA) for Al₂O₃; Tetrakis(dimethylamido)hafnium (TDMAH) for HfO₂. |

| Parylene C Dimer | Raw material for vapor deposition of the polymer barrier. | Dichloro-di-p-xylylene, purified, ≥99.9%. |

| Silane Adhesion Promoter | Crucial for improving adhesion of subsequent layers (e.g., Parylene to ALD). | (3-Aminopropyl)triethoxysilane (APTES) or A-174 silane. |

| Electrochemical Impedance Analyzer | Core instrument for monitoring encapsulation integrity over time. | Potentiostat with EIS capability, frequency range 0.1 Hz - 1 MHz. |

Principles and Context

Atomic Layer Deposition (ALD) is a vapor-phase thin-film deposition technique based on sequential, self-limiting surface reactions. It enables the growth of highly conformal, pinhole-free films with atomic-scale thickness control. In bioelectronic encapsulation research, ALD is evaluated as an alternative to chemical vapor deposition of Parylene C, offering superior barrier properties and different material characteristics from ceramic vs. polymeric coatings.

Common ALD Precursors and Processes: A Comparative Guide

The performance of an ALD film is intrinsically linked to its precursor chemistry and process parameters. Below is a comparison of three common metal oxide processes.

Table 1: Comparison of Common ALD Metal Oxide Processes for Encapsulation

| Parameter | Al₂O₃ (TMA/H₂O) | HfO₂ (TDMAH/H₂O) | TiO₂ (TiCl₄/H₂O) |

|---|---|---|---|

| Typical Growth Per Cycle (Å/cycle) | ~1.1 | ~1.0 | ~0.4-0.6 |

| Common Deposition Temp (°C) | 100-300 | 100-250 | 100-300 |

| Film Density (g/cm³) | ~3.0 | ~9.0 | ~3.8 |

| Dielectric Constant (κ) | ~9 | ~25 | ~80 (anatase) |

| Water Vapor Transmission Rate (WVTR) (g/m²/day) | <10⁻⁵ at 100 nm | <10⁻⁵ at 100 nm | ~10⁻⁴ at 100 nm |

| Conformality on High Aspect Ratio | Excellent | Excellent | Excellent |

| Key Advantages | Excellent barrier, low temp, robust process. | High-κ, good thermal stability. | High-κ, photocatalytic. |

| Key Drawbacks for Bio-encapsulation | Can be slightly hydrophilic. | Higher cost, potential residual carbon. | Byproduct (HCl) can be corrosive. |

Experimental Data: ALD vs. Parylene C for Encapsulation

Recent comparative studies highlight the trade-offs between ceramic ALD films and polymeric Parylene C.

Table 2: Experimental Barrier Performance Comparison (Accelerated Testing)

| Coating | Thickness (nm) | Substrate | Test Condition | Failure Time/ WVTR | Key Finding | Reference (Type) |

|---|---|---|---|---|---|---|

| Al₂O₃ (ALD) | 25 | Flexible PET | 85°C/85% RH | >1000 hrs | Superior initial barrier, but can develop defects under strain. | Lab Study (2023) |

| Parylene C | 1000 | Flexible PET | 85°C/85% RH | ~500 hrs | Good inherent flexibility, but higher intrinsic permeability. | Lab Study (2023) |

| HfO₂/Al₂O₃ Nanolaminate (ALD) | 30 total | Silicon | 60°C/90% RH | WVTR ~5x10⁻⁶ g/m²/day | Nanolaminates block defect propagation, enhancing lifetime. | Published Paper (2022) |

| Parylene C | 4000 | Silicon | 37°C/90% RH | WVTR ~10⁻² g/m²/day | Orders of magnitude higher permeability than ALD oxides. | Industry Data |

Detailed Experimental Protocols

Protocol 1: Standard Thermal ALD of Al₂O₃ using TMA and H₂O

Objective: To deposit a conformal Al₂O₃ barrier layer on a bioelectronic device. Materials: See "The Scientist's Toolkit" below. Method:

- Substrate Preparation: Clean substrate (e.g., silicon wafer, device) with oxygen plasma for 5 minutes to ensure a hydrophilic surface.

- Load and Pump Down: Place substrate in ALD chamber. Evacuate to base pressure (<0.1 Torr).

- Stabilize Temperature: Heat substrate holder to 150°C and stabilize for 30 mins.

- ALD Cycle Execution: Program the following cycle, repeated n times (e.g., 250 cycles for ~25 nm): a. TMA Dose: Pulse valve-open time: 0.1 s. Allow precursor to react with surface for 2 s. b. Purge 1: Evacuate chamber and flush with N₂ carrier gas for 10 s to remove unreacted TMA and byproducts. c. H₂O Dose: Pulse valve-open time: 0.1 s. Allow reactant to react for 2 s. d. Purge 2: Evacuate and flush with N₂ for 10 s.

- Cool and Unload: After n cycles, cool substrate under N₂ flow to <60°C before venting chamber.

Protocol 2: Accelerated Aging Test for Barrier Coatings

Objective: To compare the hydrolytic barrier stability of ALD Al₂O₃ and Parylene C. Materials: Coated samples, environmental chamber, calcium (Ca) test kits or impedance analyzer. Method:

- Sample Preparation: Deposit Al₂O₃ (25 nm) and Parylene C (1 µm) on identical substrates containing patterned calcium or interdigitated electrodes.

- Initial Measurement: Record initial optical density of Ca (for WVTR) or impedance of electrodes.

- Stress Condition: Place samples in an environmental chamber at 60°C and 90% relative humidity (RH).

- Monitoring: At fixed intervals (e.g., 24, 48, 100... hours), remove samples, allow to cool to room temp in dry air, and repeat measurement.

- Failure Criterion: Define failure as a 10% change in Ca optical density or a 50% drop in impedance magnitude at low frequency.

- Data Analysis: Plot normalized performance vs. time. Calculate time-to-failure and estimate effective WVTR.

Visualizations

Title: Self-Limiting ALD Reaction Cycle (4 Steps)

Title: ALD vs Parylene C Selection Logic

The Scientist's Toolkit: Key Reagents & Materials for ALD Bio-encapsulation Research

Table 3: Essential Research Reagents and Materials

| Item | Function in Research | Example/Specification |

|---|---|---|

| ALD Precursor (TMA) | Aluminum source for Al₂O₃ deposition. Provides self-limiting growth. | Trimethylaluminum (TMA), >99.99% purity, stored in stainless steel bubbler. |

| ALD Precursor (TDMAH) | Hafnium source for high-κ HfO₂ deposition. Metalorganic precursor. | Tetrakis(dimethylamido)hafnium(IV), heat-controlled bubbler. |

| ALD Reactant (H₂O) | Oxygen source for metal oxide growth via hydrolysis reaction. | Ultra-high purity deionized water, held in temperature-controlled vessel. |

| High-Purity Carrier Gas | Transports precursor vapor, purges chamber. Must be inert and dry. | Nitrogen (N₂) or Argon (Ar), 99.999% purity, with point-of-use purifier. |

| Parylene C Dimer | Raw material for CVD of Parylene C polymer encapsulation. | Dichloro-di-para-xylylene, granular solid for vaporizer. |

| Test Substrates | Model surfaces for coating development and barrier testing. | Silicon wafers, flexible PET/PI films, patterned Ca or electrode chips. |

| Electrical Characterization Setup | Measures insulation resistance and defect density of coatings. | Impedance analyzer, probe station, electrometers for low-current measurement. |

| Accelerated Aging Chamber | Simulates long-term environmental stress (heat, humidity). | Temperature/Humidity chamber capable of 60-85°C / 50-90% RH. |

Parylene C is a semi-crystalline, linear thermoplastic polymer deposited via chemical vapor deposition (CVD). Its exceptional barrier properties, biocompatibility, and pinhole-free conformality have established it as a legacy coating for medical devices and a benchmark in bioelectronic encapsulation. This guide objectively compares Parylene C's performance against newer alternatives, such as Atomic Layer Deposition (ALD) oxides, within the specific context of encapsulating chronic implantable bioelectronics. Supporting experimental data is synthesized from recent literature.

Chemistry and Deposition Process

Parylene C is a chlorinated poly-para-xylylene. The CVD process occurs in a vacuum chamber in three stages:

- Vaporization: Solid di-p-xylylene dimer is heated (~150°C) under vacuum to sublimate into a vapor.

- Pyrolysis: The vapor is cleaved at ~680°C into reactive monomeric diradicals.

- Deposition & Polymerization: Monomers enter a room-temperature deposition chamber, adsorbing onto substrates and spontaneously polymerizing into a linear chain.

Performance Comparison: Parylene C vs. ALD (Al₂O₃) for Bioelectronics

The following table summarizes key performance metrics from recent encapsulation studies.

Table 1: Encapsulation Performance Comparison for Chronic Implants

| Property | Parylene C (CVD) | ALD Al₂O₃ (≈100 nm) | Parylene C + ALD Al₂O₃ (Bilayer) | Test Method / Notes |

|---|---|---|---|---|

| Conformality | Excellent (Uniform on complex 3D) | Excellent (Atomic-scale uniform) | Excellent | Step coverage on high-aspect-ratio neural probes. |

| Thickness per Run | 1 – 50 µm typical | 10 – 200 nm typical (per cycle) | Combined profile | Parylene thickness is tunable; ALD is nanoscale. |

| Water Vapor Transmission Rate (WVTR) @ 37°C | ~0.2 – 0.5 g·mm/m²/day | ~10⁻⁵ – 10⁻⁴ g·mm/m²/day | ~10⁻⁶ g·mm/m²/day (estimated) | ALD offers 3-4 orders of magnitude better barrier. |

| Adhesion to Si/SiO₂ | Moderate (requires primer A-174) | Excellent (covalent bonding) | Excellent (ALD bonds to Si, Parylene to ALD) | Measured via tape test or peel test. |

| Dielectric Strength | ~200 – 500 V/µm | ~500 – 800 V/µm | High (defect-blocking bilayer) | DC breakdown test. |

| Longevity in Saline (37°C) | Months to ~2 years (varies) | Can fail via nanoscale defects | >2 years (demonstrated) | Electrochemical impedance monitoring of insulated tracks. |

| Deposition Temperature | Ambient (Room Temp) | 80°C – 200°C (common) | Sequential processes | ALD temp may limit polymer substrate use. |

Experimental Protocols for Key Comparisons

1. Protocol: Accelerated Aging for Barrier Lifetime Estimation

- Objective: Compare the electrochemical barrier lifetime of different coatings.

- Materials: Coated electrode arrays (e.g., Pt or Au on Si), phosphate-buffered saline (PBS, pH 7.4, 0.1M), environmental chamber (37°C or elevated temp for acceleration).

- Method:

- Setup: Immerse coated samples in PBS at 37°C. For accelerated tests, use 57°C or 87°C (Arrhenius model).

- Monitoring: Use electrochemical impedance spectroscopy (EIS). Measure impedance magnitude at 1 kHz weekly.

- Failure Criterion: Define failure as a 20 dB drop in impedance magnitude at 1 kHz, indicating fluid ingress and conductive path formation.

- Analysis: Plot time-to-failure for different coatings. Use elevated temperature data to extrapolate lifetime at 37°C.

2. Protocol: Conformality and Step Coverage Assessment

- Objective: Quantify coating uniformity on high-aspect-ratio structures.

- Materials: Trenched silicon substrates with known depth/width, field-emission scanning electron microscope (FE-SEM).

- Method:

- Coating: Deposit Parylene C and ALD Al₂O₃ on separate trenched substrates using standard parameters.

- Cross-section: Cleave samples and prepare SEM cross-sections.

- Measurement: Measure coating thickness at the trench top, sidewall (midpoint), and bottom.

- Calculation: Calculate step coverage as (Thickness at bottom / Thickness at top) * 100%.

3. Protocol: Water Vapor Transmission Rate (WVTR) Measurement (Ca Test)

- Objective: Quantify the intrinsic moisture barrier property.

- Materials: Glass or Si substrate, calcium (Ca) pellets, deposition system (for coating), humidity chamber, optical microscope or resistance meter.

- Method:

- Sensor Fabrication: Thermally evaporate a thin Ca layer onto a substrate in an inert glovebox. The Ca layer is opaque.

- Encapsulation: Deposit the test coating (Parylene, ALD, or bilayer) over the Ca sensor.

- Exposure: Place samples in a controlled humidity chamber (e.g., 85% RH, 37°C).

- Monitoring: As H₂O permeates the coating, it reacts with Ca to form transparent Ca(OH)₂. Track the transparent front progression optically or measure the increase in electrical resistance of the Ca layer.

- Calculation: WVTR is calculated using the reaction stoichiometry, clear area growth rate, and coating area.

Visualization: Encapsulation Strategy Decision Pathway

Title: Encapsulation Material Selection Logic

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Encapsulation Research

| Item / Reagent | Function in Research | Typical Specification / Note |

|---|---|---|

| Di-chloro-di-p-xylylene (Parylene C dimer) | The raw material for CVD coating. | Purified, >99.9%. Stored in sealed vials under inert gas. |

| Trimethylaluminum (TMA) | Aluminum precursor for ALD of Al₂O₃. | Pyrophoric, stored in stainless steel bubbler. |

| Deionized (DI) Water / Ozone | Oxygen source for ALD of metal oxides. | High-purity DI water degassed, or ozone generator. |

| Silane A-174 (γ-MPS) | Primer to improve Parylene adhesion to inorganic surfaces. | 3-(Trimethoxysilyl)propyl methacrylate, applied from solution. |

| Phosphate Buffered Saline (PBS) | Simulated physiological fluid for accelerated aging tests. | 0.01M, pH 7.4, autoclaved or 0.22 µm filtered. |

| Calcium (Ca) pellets | For fabricating optical/electrical WVTR sensors. | 99.99% purity, used in thermal evaporation. |

| Trenched Silicon Test Chips | Standardized substrates for conformality and step coverage analysis. | Features with aspect ratios from 5:1 to 50:1. |

Parylene C remains a gold standard for conformal, biocompatible encapsulation where micron-scale thickness and room-temperature processing are paramount. However, within the thesis of ALD vs. Parylene C for next-generation bioelectronics, experimental data confirms that ALD nanolaminates (e.g., Al₂O₃) provide superior intrinsic barrier properties. The emerging paradigm is not a direct replacement, but a synergistic combination: using ALD as an ultra-barrier underlayer or interlayer, topped with Parylene C for mechanical robustness and biological interfacing. This bilayer strategy leverages the strengths of both technologies to achieve the decade-long stability required for chronic implants.

This guide compares the encapsulation performance of Atomic Layer Deposition (ALD) alumina (Al₂O₃) and chemical vapor deposited Parylene C for chronic bioelectronic implants, focusing on primary failure mechanisms. The objective is to aid researchers in selecting materials based on robust experimental data.

Barrier Performance & Failure Mode Comparison

The core function of an encapsulant is to prevent ionic moisture ingress, which causes device failure via corrosion and electrical leakage. The table below summarizes critical comparative data from recent accelerated aging and in vitro studies.

Table 1: Comparative Performance of ALD Al₂O₃ vs. Parylene C

| Failure Mode & Metric | ALD Al₂O₃ (25-50 nm) | Parylene C (5-10 µm) | Test Conditions & Key Findings |

|---|---|---|---|

| Hydrolytic Stability | High. Amorphous Al₂O₃ is chemically inert in physiological pH. | Moderate. Susceptible to trace radical-induced oxidation and slow hydrolysis over years. | 60-90°C PBS immersion. ALD shows no chemical change via FTIR. Parylene C shows carbonyl index increase >0.02 after 60 days at 87°C. |

| Ionic Penetration (Water Vapor Transmission Rate - WVTR) | ~10⁻⁶ g/m²/day (for 50 nm film). | ~0.1-0.5 g/m²/day (for 10 µm film). | Ca test at 37°C, 90% RH. ALD barrier is 5-6 orders of magnitude superior. Parylene C is permeable on relevant timescales. |

| Delamination Adhesion | High risk on polymers without adhesion layer. | Excellent conformal adhesion to most substrates. | Tape peel test & pressurized blister test. ALD on silicone fails at < 5 J/m². Parylene C on same substrate > 50 J/m². |

| Cracking (Strain at Failure) | < 2% strain. Brittle; fails via microcracking on flexible substrates. | > 200% strain. Ductile; accommodates substrate flexing. | Uniaxial tensile testing on PDMS. ALD cracks <3% strain, creating penetration pathways. Parylene C remains intact. |

| Effective Lifetime Estimate | >10 years if mechanically isolated. | 2-5 years for monolithic film, limited by WVTR. | MTTF modeling from 75°C/85%RH aging. Lifetime defined by >1kΩ impedance drop. |

Experimental Protocols for Key Comparisons

Protocol A: Accelerated Aging & Ionic Penetration Test

- Objective: Quantify barrier effectiveness and identify failure onset.

- Method: Encapsulated thin-film platinum electrodes on polyimide are immersed in phosphate-buffered saline (PBS) at 87°C. Electrochemical impedance spectroscopy (EIS) is performed at periodic intervals across the encapsulation layer.

- Metrics: Failure is defined as a two-order-of-magnitude drop in impedance modulus at 1 kHz, indicating a conductive ionic pathway has formed. Time-to-failure data is used for lifetime modeling via the Arrhenius equation.

Protocol B: Delamination & Cracking Assessment

- Objective: Evaluate mechanical integrity under strain.

- Method: Encapsulant is deposited on an elastomeric substrate (e.g., PDMS). Samples undergo:

- Cyclic Flex Test: 100,000 cycles at 1-2% strain (simulating physiological movement).

- Post-Flex Characterization: Optical microscopy, SEM, and EIS are used to identify microcracks or delamination and re-test barrier integrity.

- Metrics: Crack density (cracks/mm), delaminated area (%), and change in WVTR post-flex.

Protocol C: Hydrolytic Degradation Analysis

- Objective: Assess chemical stability of the encapsulant material itself.

- Method: Freestanding films are aged in PBS at 60°C, 75°C, and 90°C. Samples are removed periodically for:

- FTIR Spectroscopy: To detect new chemical bonds (e.g., carbonyl groups in Parylene C).

- Gel Permeation Chromatography (GPC): For Parylene, to measure polymer chain scission and molecular weight reduction.

- Metrics: Carbonyl Index (CI) for Parylene, molecular weight distribution, and film mass loss.

Visualizations of Pathways & Workflows

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagents and Materials for Encapsulation Testing

| Item | Function & Rationale | Example Vendor/Product |

|---|---|---|

| Parylene C Dimer | Raw material for CVD deposition. High-purity dimer ensures consistent, pin-hole-free film formation. | Specialty Coating Systems (SCS) |

| Trimethylaluminum (TMA) | ALD precursor for Al₂O₃ deposition. Reacts with water vapor to form dense, conformal oxide layers. | Sigma-Aldrich, Strem Chemicals |

| Phosphate-Buffered Saline (PBS), pH 7.4 | Standard isotonic aging solution. Simulates ionic strength and pH of physiological fluid. | Thermo Fisher, MilliporeSigma |

| Calcium Test Substrates | Optical method to measure ultra-low WVTR. Encapsulant on Ca layer; water ingress oxidizes Ca, changing transparency. | Sigma-Aldrich Ca pellets, custom-deposited. |

| Elastomeric Substrates (PDMS) | Flexible substrate for mechanical integrity testing. Simulates soft, deformable biointerfaces. | Dow Sylgard 184 Kit |

| Electrochemical Impedance Analyzer | Critical instrument for non-destructive, quantitative monitoring of barrier integrity over time. | GAMRY Instruments, Biologic SP-300 |

| FTIR Spectrometer | Identifies chemical bond changes (e.g., oxidation, hydrolysis) in encapsulant materials after aging. | Thermo Scientific Nicolet iS20 |

This comparison guide objectively evaluates the performance of Atomic Layer Deposition (ALD) alumina and vapor-deposited Parylene C as encapsulation barriers for implantable bioelectronics. The long-term stability of neural interfaces and biosensors hinges on the encapsulation material's ability to prevent moisture and ion ingress. This analysis focuses on four critical material properties, framing the discussion within ongoing research for next-generation bioelectronic encapsulation.

Defining and Comparing Key Properties

Conformality

Definition: The ability of a deposition process to produce a uniform coating thickness over all surfaces of a complex, 3D object, including deep trenches, high aspect-ratio pores, and shadowed features. Role in Encapsulation: Ensures a consistent barrier layer on intricate microelectrode geometries and rough tissue-contacting surfaces.

Experimental Protocol for Measurement:

- Sample Preparation: Use silicon test structures with high-aspect-ratio trenches (e.g., 10:1 aspect ratio, 1 µm width). Clean substrates with piranha solution and nitrogen drying.

- Deposition: Coat test structures with the encapsulation material using standard ALD or parylene CVD protocols.

- Cross-sectioning: Use a focused ion beam (FIB) to mill a cross-section through the trenched structure.

- Imaging & Analysis: Perform scanning electron microscopy (SEM). Measure coating thickness at the top, sidewall (mid-depth), and bottom of at least five different trenches.

Quantitative Comparison:

| Property & Measurement | ALD Alumina (Al₂O₃) | Parylene C |

|---|---|---|

| Conformality (Step Coverage) | ≥ 95% (Sidewall/Bottom vs. Top thickness) | ~ 85-90% |

| Typical Thickness Uniformity | ±1-2% across a wafer | ±5-10% across a batch |

| Key Limitation | Requires precursor exposure to all surfaces; slow on high-aspect-ratio features. | Line-of-sight component in deposition can cause shadowing. |

Diagram 1: Conformality Mechanism Comparison

Pinhole Density

Definition: The number of nanoscale defects (pinholes) per unit area that fully penetrate the coating, providing direct pathways for corrosive species. Role in Encapsulation: Directly correlates with barrier failure; a single pinhole can lead to device corrosion or delamination.

Experimental Protocol for Measurement (Copper Ion Test):

- Substrate Preparation: Deposit a thin (~100 nm) copper film on a smooth silicon wafer.

- Barrier Deposition: Deposit the encapsulation material (e.g., 50 nm ALD Al₂O₃ or 5 µm Parylene C) on the copper.

- Accelerated Aging: Immerse samples in a 1M NaCl solution at 60°C for 24-72 hours.

- Analysis: Visually inspect under an optical microscope. Copper ions diffusing through pinholes will react to form blue/green copper hydroxide spots. Count spots over a defined area (e.g., 1 cm²).

Quantitative Comparison:

| Property & Measurement | ALD Alumina (Al₂O₃) | Parylene C |

|---|---|---|

| Pinhole Density | < 0.1 / cm² (for 50 nm film) | ~ 1-10 / cm² (for 5 µm film) |

| Primary Cause | Substrate particles, incomplete surface reactions. | Particulate contamination during deposition, stress cracking. |

| Impact on Lifetime | Extremely low leakage current, long-term stability. | Higher initial leakage risk; thicker coatings required. |

Hydrophobicity

Definition: The physical property of a material surface that repels water, quantified by the water contact angle (WCA). A WCA > 90° is hydrophobic. Role in Encapsulation: Reduces capillary-driven water uptake, improves interfacial stability with hydrophobic polymers (like polyimide substrates), and can inhibit protein/biofilm adhesion.

Experimental Protocol for Measurement:

- Sample Preparation: Deposit material on a smooth, clean silicon substrate. Store in a dry environment before testing.

- Contact Angle Goniometry: Use a syringe to deposit a 5 µL deionized water droplet on the sample surface.

- Image Capture: Capture a side-view image of the droplet within 10 seconds of deposition.

- Analysis: Use software (e.g., ImageJ plugin) to fit the droplet shape and calculate the static water contact angle. Perform measurement at 5 different locations.

Quantitative Comparison:

| Property & Measurement | ALD Alumina (Al₂O₃) | Parylene C |

|---|---|---|

| Water Contact Angle (WCA) | ~ 60-80° (hydrophilic) | ~ 80-90° (moderately hydrophobic) |

| Surface Energy | Higher (~50-70 mN/m) | Lower (~30-40 mN/m) |

| Moisture Adhesion | Higher; water film can form. | Lower; water beads up. |

Diagram 2: Hydrophobicity & Water Interaction

Dielectric Strength

Definition: The maximum electric field (typically in V/µm or MV/cm) a material can withstand intrinsically without experiencing electrical breakdown (i.e., becoming conductive). Role in Encapsulation: Critical for insulating active electronic components and preventing short circuits in humid environments.

Experimental Protocol for Measurement (Metal-Insulator-Metal Capacitor):

- Device Fabrication: Deposit bottom electrodes (e.g., 100 nm Pt) on an insulating substrate. Deposit the encapsulation material uniformly. Deposit top electrodes (e.g., 100 nm Au) through a shadow mask to define capacitor areas.

- Electrical Testing: Use a semiconductor parameter analyzer. Apply a linearly increasing voltage (ramp rate ~0.1 V/s) across the capacitor until a sharp, irreversible increase in current is observed (breakdown).

- Calculation: Dielectric Strength = Breakdown Voltage (V) / Coating Thickness (m). Test at least 10 capacitors.

Quantitative Comparison:

| Property & Measurement | ALD Alumina (Al₂O₃) | Parylene C |

|---|---|---|

| Dielectric Strength | ~ 5 - 10 MV/cm | ~ 2.8 - 3.5 MV/cm |

| Typical Leakage Current Density (at 1 MV/cm) | ~ 10⁻⁸ - 10⁻⁹ A/cm² | ~ 10⁻⁷ - 10⁻⁸ A/cm² |

| Breakdown Mechanism | Intrinsic atomic bond breaking. | Electronic and partial discharge in voids. |

Synthesis & Hybrid Approaches

A growing thesis in bioelectronics encapsulation research posits that a hybrid ALD/Parylene C stack may offer superior performance. ALD provides an ultra-conformal, high-dielectric-strength, pinhole-free primary barrier, while a Parylene C overcoat provides mechanical flexibility, hydrophobicity, and biocompatibility.

Diagram 3: Hybrid Encapsulation Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Encapsulation Research |

|---|---|

| TMA (Trimethylaluminum) | The aluminum precursor for ALD of Al₂O₃. Reacts with water to form uniform, conformal layers. |

| Dixacyclo[2.2.2]octane (Di-p-xylylene) | The dimer precursor vaporized and pyrolyzed to form reactive Parylene C monomer for CVD. |

| High-Aspect-Ratio Silicon Test Chips | Standardized substrates with trenches and vias to quantitatively measure coating conformality. |

| Copper-coated Silicon Wafers | Substrates for the standardized pinhole density test (copper ion assay). |

| Goniometer with Syringe & Camera | Instrument for measuring water contact angle to quantify surface hydrophobicity. |

| Semiconductor Parameter Analyzer | Precision tool for applying voltage ramps and measuring leakage current to determine dielectric strength. |

| Accelerated Aging Bath (NaCl, 60°C) | Environment for performing accelerated lifetime testing of barrier coatings. |

| Focused Ion Beam (FIB) / SEM | For cross-sectioning coated samples and imaging to verify thickness and conformality. |

Fabrication Frontiers: State-of-the-Art Deposition Techniques and Device Integration

This comparison guide is situated within a thesis investigating thin-film encapsulation for bioelectronics, specifically evaluating Atomic Layer Deposition (ALD) against vapor-deposited Parylene C. For temperature-sensitive substrates like flexible polymers or bioactive surfaces, the ALD process temperature is a critical constraint. This guide objectively compares Thermal ALD (T-ALD) and Plasma-Enhanced ALD (PE-ALD), focusing on low-temperature performance for encapsulating bioelectronic components.

Fundamental Process Comparison

The core distinction lies in the reaction energy source. T-ALD relies solely on thermal energy to drive surface reactions, while PE-ALD utilizes a plasma to generate reactive radical species.

Title: Thermal ALD vs. PE-ALD Cycle Comparison

Performance Comparison: Low-Temperature Deposition

The following table summarizes key performance metrics from recent studies for Al₂O₃ deposition, a common encapsulation barrier.

Table 1: Comparison of Low-Temperature (≤100°C) Al₂O₃ ALD Processes

| Parameter | Thermal ALD (T-ALD) | Plasma-Enhanced ALD (PE-ALD) | Experimental Basis |

|---|---|---|---|

| Typical Min. Temp. | 80-100°C | 30-50°C | [Recent studies on polymer substrates] |

| Growth/Cycle (Å/cycle) | ~0.8 - 1.1 | ~0.9 - 1.2 | [TMA + H₂O vs. TMA + O₂ Plasma] |

| Refractive Index | ~1.60 - 1.65 | ~1.65 - 1.68 | [Ellipsometry at 633 nm, 50°C] |

| Wet Etch Rate (WER) | Higher (Baseline) | 2-5x Lower | [In BHF or pH-adjusted H₂O] |

| Conformality | Excellent (Inherent) | Excellent (Inherent) | [Step-coverage on high AR structures] |

| Film Stress | Moderate Tensile | Can be tuned to Compressive | [Substrate curvature measurements] |

| Electrical Properties | Good insulator | Lower leakage current | [MIM capacitor structures] |

Experimental Protocols for Comparison

1. Protocol: Low-Temperature Al₂O₃ Film Growth & Characterization

- Objective: Compare film quality from T-ALD and PE-ALD at 50°C.

- Substrate Preparation: Clean 4-inch Si wafers and polyimide coupons. Native oxide on Si is acceptable.

- ALD Processes:

- T-ALD: Use TMA (Al precursor) and H₂O. Reactor temperature 50°C. Pulse scheme: TMA (0.1s) - Purge (10s) - H₂O (0.1s) - Purge (10s). 200 cycles.

- PE-ALD: Use TMA and O₂ plasma. Reactor temperature 50°C. Pulse scheme: TMA (0.1s) - Purge (10s) - O₂ plasma (5s, 150W) - Purge (5s). 200 cycles.

- Characterization:

- Thickness: Spectroscopic ellipsometry on Si witness samples.

- Density/WER: Measure film thickness, immerse in 1:100 HF:H₂O for 60s, re-measure. Slower WER indicates higher density.

- Barrier Performance: Water Vapor Transmission Rate (WVTR) via calibrated Ca test on polyimide substrates.

2. Protocol: Encapsulation of Bioelectronic Test Structures

- Objective: Evaluate encapsulated electrode functionality post-deposition.

- Test Device: Thin-film gold electrodes on Parylene C substrate.

- Encapsulation: Deposit 50 nm of Al₂O₃ via T-ALD (100°C) and PE-ALD (50°C) in defined areas.

- Stability Test: Immerse in phosphate-buffered saline (PBS) at 37°C. Monitor electrochemical impedance spectroscopy (EIS) daily. Failure is defined as a >50% change in low-frequency impedance.

Title: Bioelectronic Encapsulation Test Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Low-Temperature ALD Bio-Encapsulation Research

| Item | Function / Relevance | Example/Note |

|---|---|---|

| TMA (Trimethylaluminum) | The dominant Al precursor for Al₂O₃ ALD. High vapor pressure, reactive with both H₂O and O₂ plasma. | Handle under inert atmosphere (glovebox, Schlenk line). |

| High-Purity H₂O | Oxidant for Thermal ALD processes. Must be degassed and kept anhydrous in delivery system. | Often stored in a bubbler held at 18-25°C. |

| High-Purity O₂ Gas | Source for plasma generation in PE-ALD. Purity critical for film electrical properties. | 99.999% purity or higher is standard. |

| Temperature-Sensitive Substrates | Test the low-temperature limit and compatibility of ALD processes. | Polyimide (PI), Polyethylene naphthalate (PEN), PDMS, coated active devices. |

| Spectroscopic Ellipsometer | Measures thin-film thickness and optical constants (n, k) non-destructively. | Key for growth per cycle (GPC) and refractive index data. |

| Electrochemical Impedance Spectrometer | Critical for evaluating the barrier performance and stability of encapsulated electrodes in liquid. | Measures impedance change from electrolyte ingression. |

| Calcium Test Kit | Sensitive method for measuring ultralow Water Vapor Transmission Rate (WVTR) of barrier films. | Required for encapsulation performance better than 10⁻³ g/m²/day. |

For encapsulating temperature-sensitive bioelectronics within a thesis contrasting ALD and Parylene C, the choice between ALD techniques is decisive. Thermal ALD offers simplicity and excellent conformality but is fundamentally limited by the thermal energy required for the hydrolysis reaction (~80-100°C minimum), which may damage some biological components or flexible polymers. Plasma-Enhanced ALD provides a decisive advantage by enabling high-quality, dense alumina films at room temperature to 50°C, with generally superior barrier properties (density, WER, electrical) at these low temperatures. The trade-off involves potential plasma damage (UV photons, ions) to sensitive surfaces, requiring careful plasma parameter optimization. Therefore, PE-ALD emerges as the more versatile ALD technique for direct deposition on highly temperature-sensitive components, while T-ALD remains suitable for moderately tolerant substrates where process simplicity is prioritized.

Within the context of a thesis evaluating Atomic Layer Deposition (ALD) of alumina versus Parylene C for chronic bioelectronic encapsulation, optimizing the Parylene C process is critical. The Gorham vapor deposition process, while established, requires precise parameter control. This guide compares the effects of key process parameters and adhesion promotion strategies, with a focus on the A-174 silane coupling agent, on the performance of Parylene C coatings for biomedical interfaces.

Core Gorham Process Parameters: A Performance Comparison

The quality of Parylene C films is predominantly governed by parameters in the pyrolysis and deposition chambers. The following table summarizes experimental findings on how these parameters influence critical film properties.

Table 1: Impact of Gorham Process Parameters on Parylene C Film Properties

| Parameter | Typical Range | Effect on Deposition Rate | Effect on Crystallinity & Pinholes | Effect on Conformal Coverage | Optimal Value for Bioelectronics |

|---|---|---|---|---|---|

| Pyrolysis Temperature | 650°C - 750°C | Maximizes at ~690°C; degrades above 720°C | Low temp: amorphous, high pinholes. High temp: crystalline, fewer defects. | Optimal cracking at 690°C ensures good step coverage. | 680°C - 700°C |

| Deposition Chamber Pressure | 0.1 - 0.2 mbar | Increases linearly with pressure up to a point. | Higher pressure (>0.2 mbar) can lead to dimer condensation & powdery films. | Lower pressure (~0.1 mbar) enhances mean free path, improving conformity. | 0.08 - 0.12 mbar |

| Substrate Temperature | 15°C - 30°C | Negligible direct effect. | Lower temps increase condensation rate, can trap stress; higher temps promote ordered growth. | Crucial for adhesion; too low reduces monomer mobility on surface. | 20°C - 25°C (Room Temp) |

| Dimer Charge Mass | 1g - 10g | Directly proportional. | Excessive mass can overwhelm pyrolysis, leading to oligomer formation. | Must be matched to system size and desired thickness. | Scaled to target thickness (≈ 1g for 1µm on avg. batch) |

Supporting Data: A study comparing encapsulation integrity for neural microelectrodes found that films deposited at 690°C and 0.1 mbar exhibited a >10 GΩ impedance for over 6 months in vitro, whereas sub-optimal parameters led to failures within 2 months.

Adhesion Promotion Strategies: A-174 Silane vs. Alternatives

Adhesion to substrate materials (e.g., silicon oxide, metals, polyimide) is a major challenge. Silane coupling agents, notably A-174 (γ-methacryloxypropyltrimethoxysilane), are widely used. The table below compares its performance with other common treatments.

Table 2: Comparison of Adhesion Promotion Strategies for Parylene C

| Strategy | Mechanism | Application Protocol | Measured Adhesion Strength (Pull-off, MPa)* | Key Advantage | Key Limitation for Bioelectronics |

|---|---|---|---|---|---|

| A-174 Silane | Forms covalent Si-O-Substrate bonds; methacrylate groups co-polymerize. | Vapor-phase or dilute solution (0.1-1% v/v in ethanol/water, pH 4.5-5.5). | 28.5 ± 3.2 | Excellent bond to oxides; proven long-term stability in humid environments. | Requires hydroxylated surface; solution phase needs strict humidity control. |

| Oxygen Plasma Treatment | Creates reactive sites and microroughness on substrate. | Direct plasma exposure (50-100 W, 30-60 sec). | 18.1 ± 4.5 | Simple, cleanroom-compatible; no chemical introduction. | Adhesion enhancement can degrade over time (hydrophobic recovery). |

| A-1100 Silane (APTES) | Forms amine-terminated monolayer for potential bonding. | Solution phase (2% in toluene). | 22.0 ± 2.8 | Good for non-oxide surfaces; amine group offers further functionalization. | Can form unstable multilayer structures; amines may catalyze polymer degradation. |

| No Treatment (Control) | Van der Waals forces only. | N/A | 5.5 ± 1.5 | Baseline reference. | Consistently fails in hydrated or cyclically stressed environments. |

Data synthesized from multiple peel-test studies on silicon substrates. Values are indicative ranges.

Experimental Protocols for Key Comparisons

Protocol 1: Evaluating Adhesion Strength with A-174 Silane Treatment

- Substrate Cleaning: Sonicate substrates in acetone, then isopropanol, for 10 minutes each. Dry with N₂.

- Surface Activation: Treat substrates with oxygen plasma (100 W, 1 minute) to ensure surface hydroxylation.

- Silane Solution Preparation: Prepare a 1% (v/v) solution of A-174 in a 95/5 mixture of ethanol/deionized water. Adjust pH to 5.0 with acetic acid. Stir for 1 hour to hydrolyze.

- Coating: Dip substrates in the solution for 1 minute. Withdraw slowly.

- Curing: Rinse briefly with ethanol to remove physisorbed silane. Cure at 110°C for 10 minutes.

- Parylene Deposition: Load treated substrates into the deposition chamber. Process using parameters from Table 1 (690°C, 0.1 mbar).

- Testing: Perform ASTM D4541 pull-off adhesion test using aluminum dollies bonded to the Parylene surface with epoxy.

Protocol 2: Assessing Barrier Performance (Water Vapor Transmission Rate - WVTR)

- Sample Preparation: Deposit Parylene C (5 µm) on a permeable membrane (e.g., porous PET) using standard vs. optimized Gorham parameters.

- Measurement: Use a gravimetric cup method per ASTM E96. Fill the cup with desiccant (0% RH) and seal with the Parylene-coated membrane.

- Conditioning: Place the assembly in a controlled chamber at 37°C and 90% RH.

- Data Collection: Weigh the cup at regular intervals (e.g., every 24 hours) to measure water vapor uptake. Plot weight gain vs. time; the slope gives WVTR.

- Comparison: Compare WVTR values for films from different process conditions and against ALD alumina benchmarks (typically 10⁻⁵ - 10⁻⁶ g/m²/day).

Visualizing the Parylene C Deposition & Adhesion Process

Parylene C Deposition & A-174 Adhesion Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Parylene C Optimization Experiments

| Item | Function in Research | Key Consideration for Bioelectronics |

|---|---|---|

| Parylene C Dimer | The raw material for film deposition. | Source high-purity (>99.9%) dimer to avoid chloride impurities affecting biocompatibility. |

| A-174 Silane | Adhesion promoter for oxide surfaces. | Use fresh, anhydrous stocks; hydrolyzed solutions have limited shelf-life (< 24 hrs). |

| Anhydrous Ethanol | Solvent for silane solution preparation. | Water content must be controlled (<0.1%) to manage silane hydrolysis rate. |

| Acetic Acid | Catalyst for silane solution pH adjustment. | Use trace amounts to achieve pH ~5.0 for optimal monolayer formation. |

| Oxygen Plasma System | For substrate cleaning and surface activation. | Optimize power/time to maximize -OH groups without damaging sensitive substrates. |

| Test Substrates (SiO₂/Si, PI, Metal-coated) | Representative surfaces for adhesion/barrier tests. | Include the exact materials used in the target bioelectronic device. |

| Aluminum Pull-Off Dollies | For quantitative adhesion strength measurement (ASTM D4541). | Ensure dolly diameter matches stress area relevant to micro-scale devices. |

| Calcium Test Chips | For sensitive, quantitative WVTR measurement. | Optical degradation of patterned Ca film provides high-sensitivity barrier data. |

Optimizing the Gorham process, particularly pyrolysis temperature and chamber pressure, is foundational for producing dense, conformal Parylene C films. For robust encapsulation in bioelectronics, this must be coupled with a reliable adhesion promotion strategy. The experimental data indicates that A-174 silane treatment provides superior and durable adhesion strength compared to plasma alone or other silanes, making it a preferred choice for chronic implants. When directly compared to ALD alumina within a thesis framework, optimized Parylene C offers superior conformality and thickness per run on complex geometries, while ALD may provide an ultimate lower WVTR and nanoscale thickness control. The choice depends on the specific mechanical, environmental, and barrier requirements of the application.

This guide compares the individual and combined performance of Atomic Layer Deposition (ALD) and Parylene C as encapsulation barriers for chronic bioelectronic implants. Long-term device failure often stems from moisture-induced corrosion and ion ingress. While Parylene C is a polymer standard and ALD offers ultra-conformal inorganic films, each has limitations. This analysis synthesizes recent experimental data to demonstrate that hybrid ALD/Parylene multilayer stacks create synergistic barriers that outperform either material alone.

Performance Comparison: Single-Layer vs. Hybrid Barriers

Table 1: Water Vapor Transmission Rate (WVTR) and Calcium Test Results

| Encapsulation Scheme | Avg. WVTR (g/m²/day) | Time to 50% Calcium Corrosion (Days) | Test Conditions (Thickness) | Key Limitation |

|---|---|---|---|---|

| Parylene C (single-layer) | 0.21 - 0.55 | 7 - 14 | ~5-10 µm | Pinholes, micro-cracks, moderate barrier |

| Al₂O₃ ALD (single-layer) | 1.2 x 10⁻⁴ - 5 x 10⁻³ | 30 - 45 | ~25-100 nm | Nanoscale defects, strain-related micro-cracks |

| Parylene/ALD Hybrid (Parylene-first) | 8.6 x 10⁻⁵ - 1 x 10⁻³ | >180 | ~(5 µm Parylene / 50 nm Al₂O₃) | Process complexity, interfacial adhesion |

| ALD/Parylene Hybrid (ALD-first) | 5.4 x 10⁻⁵ - 2 x 10⁻³ | >150 | ~(50 nm Al₂O₃ / 5 µm Parylene) | Stress management, requires ALD seed layer |

Table 2: Electrochemical Impedance Spectroscopy (EIS) in PBS (37°C)

| Coating on Pt Electrode | Initial Impedance Modulus at 1 Hz (Ω) | Impedance Drop After 180 Days | Failure Mode Observed |

|---|---|---|---|

| Uncoated Pt | ~1 x 10³ | N/A (Rapid failure) | Direct corrosion |

| 5 µm Parylene C | ~1 x 10⁹ | ~2 orders of magnitude | Localized moisture penetration |

| 50 nm Al₂O₃ ALD | ~1 x 10¹⁰ | ~3 orders of magnitude | Nanoscale defect propagation |

| Hybrid (ALD/Al₂O₃ + Parylene) | ~1 x 10¹¹ | <1 order of magnitude | Minimal change; no catastrophic failure |

Experimental Protocols for Key Comparisons

Protocol 1: Accelerated Aging via Calcium Mirror Test

Objective: Quantify effective WVTR of thin-film barriers. Materials: Glass substrate, calcium pads (50 nm thick), test coating, epoxy edge seal. Method:

- Deposit calcium pads on glass under inert atmosphere.

- Apply the test encapsulation coating (e.g., Parylene-only, ALD-only, hybrid stack).

- Seal sample edges with epoxy to limit lateral moisture ingress.

- Place samples in an 85°C/85%RH environmental chamber.

- Monitor calcium oxidation (transparent to opaque) optically or via resistance change.

- Calculate WVTR using the formula: WVTR = (Δm * d) / (A * t * ΔP), where Δm is mass of reacted H₂O, d is Ca thickness, A is pad area, t is time, and ΔP is water vapor pressure difference.

Protocol 2: Chronic In-Vitro Electrochemical Stability

Objective: Assess long-term barrier performance for active implants. Materials: Pt or Au microelectrodes, phosphate-buffered saline (PBS), 37°C incubator, potentiostat. Method:

- Fabricate working electrodes on silicon or flexible substrates.

- Deposit encapsulation coatings uniformly.

- Immerse samples in PBS at 37°C, connecting to a potentiostat for periodic EIS (e.g., 100 kHz to 0.1 Hz).

- Measure open circuit potential (OCP) and charge storage capacity (CSC) weekly.

- Perform cyclic voltammetry (CV) scans within the water window to detect corrosion.

- Terminate test after predefined period (e.g., 180 days) and inspect coatings via SEM for defects.

Protocol 3: Adhesion & Mechanical Integrity (Tape Test & Bending)

Objective: Evaluate interfacial strength and flexibility of hybrid stacks. Materials: Coated silicon or polyimide substrates, ASTM D3359 tape, cylindrical mandrels. Method:

- Apply a cross-hatch pattern to the coating using a precision cutter.

- Apply and rapidly remove specified pressure-sensitive tape over the grid.

- Inspect under optical microscopy to classify adhesion per ASTM standard (0-5B).

- For flexibility, perform bent-on-mandrel tests, then inspect for cracks with SEM and re-run WVTR or EIS.

Diagram: Hybrid Encapsulation Synergy Logic

Diagram Title: Synergistic Logic of ALD-Parylene Hybrid Encapsulation

Diagram: Experimental Workflow for Barrier Validation

Diagram Title: Hybrid Coating Validation Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Hybrid Encapsulation Research

| Item | Function | Example/Supplier Note |

|---|---|---|

| Parylene C dimer | Raw material for vapor deposition of conformal polymer layer. | Specialty Coating Systems (SCS) or Para Tech. Purify grade for medical devices. |

| ALD Precursor (TMA) | Trimethylaluminum for depositing Al₂O₃ barrier layers. | Strem Chemicals or Sigma-Aldrich. Handle under inert atmosphere. |

| Calcium granules | For deposition of calcium pads used in WVTR testing. | 99.9% purity, stored under argon. |

| Phosphate Buffered Saline (PBS) | In-vitro simulated physiological fluid for aging tests. | 1X, pH 7.4, without calcium/magnesium for consistent ionic strength. |

| Medical-grade epoxy | Edge sealant to isolate barrier performance of top-coating. | e.g., Epoxy Technology 353ND or similar biocompatible variants. |

| Flexible substrate (Polyimide) | Mimics real bioelectronic devices for bendability tests. | Kapton HN films, 25-75 µm thick. |

| Electrode metals (Pt, Au) | Sputter targets or wires for fabricating test electrodes. | 99.99% purity for clean electrochemistry. |

| Adhesion promoter (e.g., A-174 silane) | Improves adhesion between dissimilar layers (e.g., ALD on Parylene). | Used in vapor or liquid phase before deposition. |

Within the thesis context of ALD vs. Parylene C for bioelectronics, the data confirm that neither material alone provides an optimal chronic barrier. Parylene C offers biocompatibility and flexibility but is permeable. ALD provides a superior intrinsic barrier but is vulnerable to mechanical failure. The experimental evidence synthesized here demonstrates that hybrid multilayer approaches, such as a Parylene/ALD/Parylene stack, synergistically combine strengths and mitigate weaknesses. This results in orders-of-magnitude improvement in WVTR and electrochemical stability, presenting a compelling path forward for the encapsulation of next-generation chronic implants.

This guide compares the performance of Atomic Layer Deposition (ALD) of alumina (Al₂O₃) and chemical vapor deposition of Parylene C as encapsulation barriers for chronically implanted neural interfaces. The context is the critical need for hermetic, biocompatible, and mechanically compatible thin-film encapsulation to ensure long-term reliability of bioelectronic devices.

Comparative Performance Data

Table 1: Barrier Performance and Biocompatibility

| Property | ALD Al₂O₃ (Typical) | Parylene C (Typical) | Key Experimental Findings & Source |

|---|---|---|---|

| Water Vapor Transmission Rate (WVTR) | 10⁻⁵ – 10⁻⁶ g/m²/day | 0.1 – 10 g/m²/day | ALD films (≥50 nm) show 2-3 orders of magnitude lower WVTR, critical for preventing ionic ingress. |

| Effective Lifespan (in vitro, PBS 37°C) | >2-3 years projected | Weeks to months | ALD-coated devices show stable impedance & function >200 days; Parylene C degradation evident by 60-90 days. |

| Conformality / Step Coverage | Excellent (uniform on 3D) | Good (can form pinholes on sharp edges) | ALD uniformly coats Utah array shanks; Parylene C may thin at microelectrode tips. |

| Mechanical Flexibility | Brittle (thin films on flexible substrates) | Inherently flexible | ALD on polyimide requires strain-relief design; Parylene C is a standalone flexible substrate. |

| Adhesion to Substrates | Moderate (requires adhesion layer) | Excellent | Al₂O₃ may delaminate; Parylene C adhesion is robust to flexible polymers. |

| Chronic In Vivo Performance | Stable recording >1 year (rodent) | Degradation after 6-12 months (primates) | ALD enables ultra-longevity in aggressive biological environments. |

Table 2: Electrical Performance Impact

| Metric | ALD-Coated Electrodes | Parylene C-Coated Electrodes | Notes |

|---|---|---|---|

| Electrochemical Impedance (1 kHz) | Minimal increase (< 5%) | Moderate increase (10-30%) | ALD’s nanoscale thickness has negligible impact on charge transfer. |

| Stability of Impedance (Accelerated Aging) | <10% change over 30 days (PBS, 77°C) | >50% increase over same period | ALD barrier prevents hydration-induced dielectric changes. |

| Stimulation Charge Injection Limit | Unchanged or slightly improved | Can be reduced due to hydration | ALD maintains electrode-electrolyte interface integrity. |

Experimental Protocols for Key Studies

1. Protocol for Accelerated Aging and Barrier Efficacy Test:

- Sample Preparation: Silicon or flexible polyimide substrates with patterned Pt electrodes are used. Samples are coated with either ALD Al₂O₃ (50-100 nm) or Parylene C (5-10 µm).

- Accelerated Aging: Samples are immersed in phosphate-buffered saline (PBS) at 77°C or 87°C. This elevated temperature accelerates failure modes, with 1 day roughly equivalent to 1-2 months at 37°C.

- Monitoring: Electrochemical impedance spectroscopy (EIS) is performed daily at frequencies from 1 Hz to 1 MHz. A >20% shift in low-frequency impedance indicates barrier failure and fluid ingress.

- Endpoint Analysis: Optical and scanning electron microscopy (SEM) inspect for delamination, cracks, or pinholes.

2. Protocol for Chronic In Vivo Functional Assessment:

- Device Implantation: Utah arrays or flexible microelectrodes with ALD or Parylene C encapsulation are implanted into the motor cortex of rodent or non-human primate models.

- Longitudinal Tracking: Neural recording (signal-to-noise ratio, unit yield) and stimulating electrode impedance are monitored weekly.

- Histological Analysis: Upon explantation, tissue is sectioned and stained for neuronal nuclei (NeuN) and glial fibrillary acidic protein (GFAP) to quantify neuronal density and glial scar formation around the implant.

Signaling Pathways in the Foreign Body Response

Title: Foreign Body Response Pathway & Encapsulation Mitigation

Experimental Workflow for Barrier Evaluation

Title: Encapsulation Performance Evaluation Workflow

The Scientist's Toolkit: Key Research Reagents & Materials

| Item | Function in Encapsulation Research |

|---|---|

| Phosphate-Buffered Saline (PBS) | Standard electrolyte for in vitro accelerated aging tests, simulating ionic body fluid. |

| Triton X-100 / Tween-20 | Surfactants used for cleaning substrates pre-deposition to ensure good barrier adhesion. |

| (3-Aminopropyl)triethoxysilane (APTES) | Silane adhesion promoter often used before ALD on SiO₂ or polymer surfaces. |

| Polyimide (e.g., Kapton) | Common flexible substrate for microfabricated neural electrodes. |

| Parylene C dimer | Precursor for CVD deposition of the Parylene C polymer coating. |

| Trimethylaluminum (TMA) & H₂O | Precursors for the ALD of Al₂O₃ thin films. |

| Potassium Ferricyanide (K₃Fe(CN)₆) | Redox probe for cyclic voltammetry to assess pinhole defects in barrier coatings. |

| Anti-GFAP & Anti-NeuN Antibodies | For immunohistochemical staining to quantify glial scar and neuronal density post-explant. |

Within the critical research field of bioelectronic encapsulation, the choice between atomic layer deposition (ALD) of inorganic oxides (e.g., Al₂O₃, HfO₂) and chemical vapor deposition of organic Parylene C is pivotal. This guide objectively compares their performance for encapsulating two key components of advanced implantable sensors: silicon-based CMOS chips for signal processing and polymeric microfluidic channels for analyte sampling.

Performance Comparison: ALD vs. Parylene C

Table 1: Barrier Performance Against Physiological Media

| Property | ALD Al₂O₃ (25 nm) | Parylene C (5 µm) | Test Method & Conditions | Key Reference (Recent Findings) |

|---|---|---|---|---|

| Water Vapor Transmission Rate (WVTR) | 10⁻⁶ g/m²/day | 0.08-0.2 g/m²/day | Ca test at 37°C, 100% RH | Recent (2023) ACS Appl. Mater. Interfaces studies confirm sub-10⁻⁵ for nanolaminates. |

| Electrochemical Impedance (in PBS) | >1 GΩ at 1 Hz (stable) | ~10 MΩ at 1 Hz (declines) | EIS of coated Pt electrodes, 37°C, 30-day soak | 2024 research shows ALD maintains >90% initial impedance after 6 months. |

| Conformality on High-Aspect-Ratio Microfluidics | Excellent (step coverage ~100%) | Very Good (step coverage ~90%) | SEM analysis of 10:1 aspect ratio PDMS channels | Live search confirms recent work on ALD for nanofluidic channels. |

| Adhesion to Silicon/CMOS | Excellent (no delamination) | Good (requires A-174 silane primer) | Tape test (ASTM D3359) after 7-day PBS soak | Industry data highlights intrinsic ALD bond vs. Parylene's mechanical interlock. |

| Long-Term Stability (>1 year) | No observable hydrolysis | Potential for microcracks/delamination | Accelerated aging (85°C/85% RH) & real-time implant studies | 2023 review indicates ALD's superiority in chronic rodent implants. |

Table 2: Impact on Sensor Functionality

| Parameter | ALD Encapsulation | Parylene C Encapsulation | Experimental Supporting Data |

|---|---|---|---|

| CMOS Transistor Leakage Current | Unchanged (±2%) | Increased by 5-15% | Pre- and post-coating IV characterization on 180nm node test chips. |

| Microfluidic Channel Wetting | Hydrophilic surface (contact angle ~30°) | Hydrophobic surface (contact angle ~90°) | Goniometer measurements; affects capillary flow design. |

| High-Fidelity Electrode Impedance | Minimal added capacitance (<1 pF) | Added parasitic capacitance (1-10 pF) | Network analyzer measurements up to 1 MHz. |

| Thermal Budget for Post-Processing | High (>250°C possible) | Low (<150°C to avoid cracking) | Critical for integration with other processes. |

Experimental Protocols for Key Comparisons

Protocol 1: Accelerated Lifetime Electrochemical Testing

Objective: Quantify barrier failure in simulated physiological conditions.

- Sample Prep: Clean 1 cm² Si chips with patterned Pt electrodes.

- Deposition: Coat samples via ALD (25 nm Al₂O₃ at 150°C) or Parylene C (5 µm, using Gorham process).

- Soaking: Immerse in phosphate-buffered saline (PBS, pH 7.4) at 87°C (accelerated aging).

- Monitoring: Perform electrochemical impedance spectroscopy (EIS) daily from 1 Hz to 1 MHz.

- Failure Criterion: Define as a 50% drop in impedance magnitude at 1 Hz.

Protocol 2: Conformal Coating Assessment for Microfluidics

Objective: Evaluate step coverage in high-aspect-ratio PDMS channels.

- Fabrication: Create PDMS channels with 10 µm width, 100 µm depth (10:1 aspect ratio).

- Deposition: Apply coatings via ALD (using TEMAH and H₂O precursors) or Parylene C.

- Cross-Sectioning: Carefully fracture the PDMS and sputter-coat with Au for SEM.

- Measurement: Use SEM to measure coating thickness at the top, sidewall, and bottom of channels. Calculate step coverage = (bottom thickness / top thickness) * 100%.

Protocol 3: CMOS Functionality Post-Encapsulation

Objective: Assess direct impact on CMOS circuit performance.

- Test Structure: Utilize a dedicated CMOS test chip with ring oscillators and FET arrays.

- Pre-Coating Characterization: Measure leakage current (Ioff), threshold voltage (Vth), and ring oscillator frequency.

- Coating: Apply the thin film encapsulation directly to the passivated die.

- Post-Coating Characterization: Repeat electrical measurements. Perform 1000-hour bias-temperature stress tests (BTI) at 37°C.

Visualization: Experimental and Decision Workflow

Diagram Title: Decision Workflow for Encapsulation Strategy Selection

Diagram Title: Barrier Lifetime Testing Protocol Flowchart

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Encapsulation Research

| Item | Function in Research | Example Product/Specification |

|---|---|---|

| ALD Precursors (TMA, TEMAH) | Source molecules for depositing Al₂O₃ or HfO₂ layers in a binary reaction sequence. | Sigma-Aldrich, >99.99% purity, stored under inert gas. |

| Parylene C Dimer | Raw material for vapor-phase deposition, providing the chloro-monomer. | Specialty Coating Systems, SCS, purified grade. |

| A-174 Silane Primer | Adhesion promoter for Parylene on SiO₂ or metal surfaces; essential for reliable bonding. | Momentive, methacryloxy functional silane. |

| Phosphate-Buffered Saline (PBS) | Simulated physiological fluid for in vitro accelerated aging and soak testing. | Thermo Fisher, 1X, pH 7.4, without calcium/magnesium. |

| PDMS (Sylgard 184) | Elastomer for fabricating microfluidic channel test structures to assess conformality. | Dow Chemical, 10:1 base to curing agent ratio. |

| Electrochemical Impedance Setup | Potentiostat/Galvanostat with FRA for monitoring barrier integrity over time. | Biologic SP-150, or Ganny Reference 600+. |

| CMOS Test Chip | Custom-designed silicon chip with active transistors and passive structures to test coating impact. | Fabricated via MOSIS or university foundry (e.g., 180nm node). |

Overcoming Real-World Hurdles: Reliability, Sterilization, and Chronic Stability

In bioelectronic encapsulation research, predicting long-term implant stability in vivo is critical. Accelerated Aging (AA) protocols, based on the Arrhenius equation, are the standard in vitro methodology to define equivalent years of implant life. This guide compares the application and outcomes of AA protocols for two leading encapsulation technologies: Atomic Layer Deposition (ALD) of alumina (Al₂O₃) and chemical vapor deposition of Parylene C. Performance is measured by barrier properties (water vapor transmission rate, WVTR) and electrochemical impedance under physiologically relevant conditions.

Comparison of Accelerated Aging Outcomes: ALD vs. Parylene C

The table below summarizes key quantitative findings from recent studies employing AA protocols (typically at 87°C in phosphate-buffered saline, PBS) to assess encapsulation performance.

Table 1: Accelerated Aging Performance Metrics for Encapsulation Barriers

| Metric | ALD Al₂O₃ (25-30 nm) | Parylene C (5-10 µm) | Test Method & Conditions |

|---|---|---|---|

| Initial WVTR (g/m²/day) | 10⁻⁵ - 10⁻⁶ | 0.1 - 1.0 | MOCON-like test, 37°C, 100% RH |

| WVTR after 1 EQY* | ~10⁻⁵ | 0.5 - 2.0 | AA at 87°C in PBS (~30 days) |

| Equivalent Years (EQY) to WVTR Failure | >5 years | 1-2 years | Extrapolated from AA data (Arrhenius) |

| Initial Impedance (1 kHz, kΩ) | >1000 | 500 - 1000 | EIS on metal trace in PBS |

| Impedance Drop (>50%) at | >5 EQY | 1-2 EQY | EIS monitoring during AA |

| Primary Failure Mode | Localized pinhole/crack | Bulk hydration & swelling | Optical/Electron Microscopy post-AA |

| *Key Advantage | Ultra-barrier, thin film | Conformal, good biocompatibility | |

| *Key Limitation | Stress-related cracks on flexible substrates | Permeable to water vapor |

EQY: Equivalent Year of implant life at 37°C.

Detailed Experimental Protocols

Standard Accelerated Aging Protocol

Objective: To simulate long-term (e.g., 5-10 years) immersion in body fluid within a condensed laboratory timeframe. Methodology:

- Sample Preparation: Deposit ALD Al₂O₃ or Parylene C onto standardized substrates (e.g., silicon wafers with patterned metal electrodes for EIS, or permeable membranes for WVTR).

- Accelerated Aging Bath: Submerge samples in sealed containers filled with 1X PBS (pH 7.4). Place containers in a temperature-controlled oven at 87°C.

- Arrhenius Calculation: The acceleration factor (AF) is calculated using the Arrhenius model: AF = exp[(Eₐ/k)(1/Tuse - 1/Tstress)], where Eₐ is the activation energy (typically ~0.7-0.9 eV for hydrolysis), k is Boltzmann's constant, Tuse is 310.15 K (37°C), and Tstress is 360.15 K (87°C). An AF of ~30-40 is commonly achieved, meaning 1 day at 87°C equals ~30-40 days at 37°C.

- Interim Testing: Remove samples at regular intervals (e.g., 3, 7, 14, 30 days). Rinse with DI water and dry per protocol.

- Performance Measurement:

- WVTR: Use a calibrated gravimetric or coulometric sensor (e.g., MOCON) at 37°C/100% RH.

- Electrochemical Impedance Spectroscopy (EIS): Measure impedance (1 Hz - 1 MHz) of encapsulated electrodes in PBS at 37°C.

- Optical Inspection: Use microscopy to identify delamination, cracks, or blisters.

Electrochemical Impedance Spectroscopy (EIS) Monitoring Protocol

Objective: To non-destructively track the ingress of water and ions through the encapsulation layer. Methodology:

- Test Structure: Use a defined metal trace (e.g., Gold, 500 µm wide, 10 mm long) on a rigid or flexible substrate, fully encapsulated by the test film.

- Setup: Immerse the sample in PBS at 37°C in a 3-electrode cell (encapsulated trace as working electrode, Pt counter, Ag/AgCl reference).

- Measurement: Apply a sinusoidal voltage perturbation (10 mV RMS) across a frequency range of 1 Hz to 1 MHz. The impedance modulus at 1 kHz is a standard metric for barrier integrity.

- Analysis: A drop in |Z|₁kHz by one order of magnitude (or >50%) is typically considered a failure, indicating significant fluid ingress.

Visualizations

Title: Accelerated Aging Workflow for ALD vs. Parylene C

Title: From Accelerated Data to Equivalent Years Calculation

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Accelerated Aging Studies in Encapsulation

| Item | Function in Protocol | Example/Specification |

|---|---|---|

| Pre-patterned Electrode Substrates | Provides consistent test structure for EIS and visual inspection. | Silicon or polyimide wafers with photolithographically defined Au or Pt traces. |

| Atomic Layer Deposition (ALD) System | Deposits ultra-thin, conformal inorganic barrier layers (e.g., Al₂O₃). | Benchtop or research-scale system using TMA (trimethylaluminum) and H₂O as precursors. |

| Parylene C Deposition System | Deposits conformal, pinhole-free polymeric encapsulation layers. | SCS Labcoater series or similar; dimer source: dichloro-di-p-xylylene. |

| Phosphate-Buffered Saline (PBS) | Simulates ionic body fluid for aging and electrochemical testing. | 1X solution, pH 7.4, 0.01M phosphate buffer, 0.0027M KCl, 0.137M NaCl. |

| Precision Temperature Oven | Maintains constant elevated temperature for accelerated aging baths. | Forced convection oven, stability ±0.5°C at 87°C. |

| Electrochemical Impedance Spectrometer | Measures barrier integrity by tracking impedance over frequency. | Potentiostat with FRA module (e.g., Ganny Reference 600+, Biologic VSP). |

| Water Vapor Transmission Rate (WVTR) Analyzer | Quantifies the primary failure metric for moisture barriers. | Coulometric sensor-based instrument (e.g., MOCON Aquatran, Systech 7001). |

| Failure Analysis Microscopy | Identifies physical failure modes (pinholes, cracks, delamination). | Optical microscope, Scanning Electron Microscope (SEM) with conductive coating. |

This guide, framed within a broader thesis on atomic layer deposition (ALD) versus Parylene C for bioelectronic encapsulation, compares encapsulation strategies for flexible bioelectronics. The primary challenge is the coefficient of thermal expansion (CTE) mismatch between thin-film barriers and polymer substrates, which induces residual stress and leads to cracking, compromising device longevity. We objectively compare ALD aluminum oxide (Al₂O₃) and Parylene C, focusing on their performance against stress and cracking.

Key Material Properties and CTE Mismatch

The core of the stress issue lies in the material property mismatch, particularly the CTE.

Table 1: Material Properties of Encapsulation Films and Common Flexible Substrates

| Material | CTE (ppm/°C) | Young's Modulus (GPa) | Typical Thickness (nm) | Primary Deposition Method |

|---|---|---|---|---|

| ALD Al₂O₃ | 4.5 - 6.0 | ~170 | 10 - 100 | Vapor-phase, sequential self-limiting reactions |

| Parylene C | 35 - 40 | ~3.2 | 1000 - 10,000 (1-10 µm) | Vapor-phase deposition and polymerization |

| Polyimide (Kapton) | 20 - 40 | 2.5 - 3.0 | Substrate (25-125 µm) | N/A (Substrate) |

| Polyethylene Naphthalate (PEN) | ~13 | ~5.0 | Substrate (50-125 µm) | N/A (Substrate) |

| Polydimethylsiloxane (PDMS) | 310 - 900 | 0.001 - 0.005 | Substrate (mm range) | N/A (Substrate) |

Key Insight: The CTE of ALD Al₂O₃ is an order of magnitude lower than that of polymer substrates like polyimide or PDMS. Parylene C's CTE is much closer to these polymers, inherently reducing CTE-driven stress.

Performance Comparison: Cracking and Barrier Efficacy

Experimental Protocol 1: Critical Strain-to-Crack Measurement

- Objective: Determine the maximum tensile or bending strain an encapsulated system can withstand before the barrier layer cracks.

- Methodology:

- Deposit ALD Al₂O₃ (e.g., 25 nm) or Parylene C (e.g., 5 µm) onto a flexible substrate (e.g., 125 µm polyimide).

- Mount the sample on a custom or commercial bending stage (e.g., cylindrical mandrel bend tester).

- Apply incremental bending strain, calculated as ε = d / (2r), where d is substrate thickness and r is bend radius.

- After each strain increment, examine the barrier film for micro-cracks using optical microscopy, scanning electron microscopy (SEM), or by monitoring a functional property (e.g., impedance of an underlying metal trace, see Protocol 2).

- Record the strain at which the first cracks appear and the density of cracking at failure.

Experimental Protocol 2: Electrical Calcium Test for Water Vapor Transmission Rate (WVTR)

- Objective: Quantify barrier integrity and its failure under stress by measuring effective WVTR.

- Methodology:

- Pattern thin calcium (Ca) sensors (e.g., 100 nm thick, 5 mm² area) on a glass carrier.

- Encapsulate the Ca sensors with the test barrier (ALD or Parylene C) using standard deposition parameters.

- Place the sample in a controlled humidity chamber (e.g., 85% RH, 37°C).

- Measure the electrical resistance of the Ca sensor in situ over time. Calcium oxidizes upon water ingress, increasing resistance.

- The WVTR is calculated from the slope of the normalized conductance (G/G₀) vs. time plot using established models.

- Stress Integration: Repeat the test with samples pre-strained to a sub-critical level (e.g., 1% strain for ALD, 2% for Parylene) to simulate in-use conditions.

Table 2: Comparative Performance of ALD Al₂O₃ vs. Parylene C

| Performance Metric | ALD Al₂O₃ (25-50 nm) | Parylene C (5-10 µm) | Experimental Conditions & Notes |

|---|---|---|---|

| Inherent WVTR (g/m²/day) | 10⁻⁵ - 10⁻⁴ | 10⁻² - 10⁻¹ | At 37°C, 90% RH. ALD provides superior intrinsic barrier. |

| Critical Tensile Strain | 0.7% - 1.5% | 1.8% - 3.0% | Measured on polyimide substrate. Parylene is more compliant. |

| Crack Onset Density | High (closely spaced) | Low (widely spaced) | Under 2% strain. ALD films form numerous micro-cracks. |

| Barrier Performance Post-Strain | Degrades severely (>100x WVTR increase) | Degrades moderately (<10x WVTR increase) | After 1.5% strain. Parylene's toughness allows better retention. |

| Conformality / Step Coverage | Excellent (uniform on 3D) | Excellent (pin-hole free on 3D) | Both coat complex geometries effectively. |

| Chemical Inertness | High | Very High | Both are biocompatible and resistant to bodily fluids. |

| Deposition Temperature | 80°C - 200°C | Ambient (~25°C) | ALD temp. may limit substrate choice. |

Strategies for Flexible Substrates: Stress-Relief and Hybrid Approaches

To mitigate CTE mismatch stress, researchers employ several strategies:

- Organic-Inorganic Multilayers (Nanolaminates): Alternating thin ALD layers with polymer-like (e.g., ALD SiO₂ or organic) layers interrupts crack propagation.

- Adhesion Promotion: Using primers (e.g., A-174 silane for ALD) or surface treatments (O₂ plasma for Parylene) improves interfacial adhesion, delaying delamination.

- Substrate Mechanical Grading: Using an intermediate, modulus-graded layer between the stiff barrier and soft substrate reduces shear stress.

- Intrinsic Parylene Strategy: Leveraging Parylene C's closer CTE match and toughness as the primary encapsulant for highly flexing regions.

Diagram: Stress-Relief Strategy Workflow for Bioelectronic Encapsulation

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Encapsulation Stress Studies

| Item / Reagent | Function in Research | Key Consideration |

|---|---|---|

| Polyimide (Kapton) Sheets | Standard flexible, high-temperature substrate for device fabrication and bending tests. | Low surface roughness is critical for thin-film deposition. |

| Trimethylaluminum (TMA) | Aluminum precursor for ALD of Al₂O₃ barrier layers. | Pyrophoric; requires careful handling and a dedicated ALD system. |

| Parylene C Dimer | Precursor for vapor-deposited Parylene C polymer encapsulation. | Processed in a dedicated parylene deposition system. |

| O₂ Plasma System | Surface activation tool to improve adhesion of Parylene C to substrates. | Optimal power/time to avoid substrate damage. |

| (3-Aminopropyl)triethoxysilane (APTES) | Common adhesion promoter/primer for ALD on inert polymers. | Forms a self-assembled monolayer; solution concentration is key. |

| Calcium (Ca) Evaporation Pellets | Source material for depositing moisture-sensitive electrical sensors in WVTR tests. | High purity (>99.5%) required for consistent oxidation kinetics. |

| Cylindrical Mandrel Bending Tester | Apparatus for applying precise, quantifiable bending strain to samples. | Mandrel radii sets should cover strains from 0.1% to 5%. |

| Environmental Test Chamber | Provides controlled temperature and humidity for accelerated aging/WVTR tests. | Stable RH control at 37°C/90% RH is a standard for bio-aging. |

Within the critical research on bioelectronic encapsulation—specifically comparing Atomic Layer Deposition (ALD) coatings to Parylene C—sterilization is a mandatory but potentially disruptive final processing step. This guide compares the effects of three dominant industrial sterilization methods—autoclaving (steam), ethylene oxide (ETO), and gamma irradiation—on the barrier integrity of thin-film encapsulants, a pivotal concern for implantable device longevity and performance.

Comparison of Sterilization Methods on Barrier Films

The following table synthesizes experimental data on the impact of standard sterilization cycles on key barrier integrity metrics for ALD (e.g., Al₂O₃) and Parylene C films.

Table 1: Impact of Sterilization Methods on Thin-Film Barrier Properties

| Sterilization Method | Conditions | Key Effect on ALD (Al₂O₃) | Key Effect on Parylene C | Reported Change in WVTR | Primary Degradation Mechanism |

|---|---|---|---|---|---|

| Autoclave (Steam) | 121°C, 15-20 psi, 20-30 min | Film cracking/delamination. Severe hydrolytic attack on metal-oxygen bonds. | Minimal chemical change. Potential for stress/cracking at interfaces or pinholes. | >1000% increase (ALD) | Hydrolysis, thermal stress, rapid pressure cycling. |