Accelerated Aging Testing for Implantable Encapsulation Materials: Protocols, Challenges, and Best Practices for Medical Device Development

This article provides a comprehensive guide to accelerated aging testing for implantable encapsulation materials, crucial for predicting long-term stability and safety in medical devices and drug delivery systems.

Accelerated Aging Testing for Implantable Encapsulation Materials: Protocols, Challenges, and Best Practices for Medical Device Development

Abstract

This article provides a comprehensive guide to accelerated aging testing for implantable encapsulation materials, crucial for predicting long-term stability and safety in medical devices and drug delivery systems. Targeted at researchers, scientists, and development professionals, we explore the fundamental principles and rationale behind accelerated aging (ISO 11985, ASTM F1980), detailing standard methodologies including temperature-driven Arrhenius modeling and real-time degradation studies. We address common troubleshooting challenges such as material-specific failure modes, property drift, and test condition selection, offering optimization strategies for predictive accuracy. The content validates testing outcomes by comparing accelerated results with real-time data, examining case studies of silicone, parylene, and polyurethane, and discussing regulatory considerations for FDA/CE submissions. This resource synthesizes current industry practices to ensure reliable prediction of in-vivo performance and material longevity.

The Science of Simulating Time: Core Principles and Rationale for Accelerated Aging of Implantable Encapsulation Materials

The functional lifetime of an implantable medical device—from neurostimulators to drug-eluting implants—is dictated by the integrity of its encapsulation. Material degradation leads to catastrophic failure modes: moisture ingress, component corrosion, and uncontrolled drug release. Real-time aging studies are impractical for devices with 5-10+ year service lives. Therefore, accelerated aging, rooted in the Arrhenius model of chemical kinetics, is the foundational, non-negotiable methodology for predicting long-term stability and ensuring patient safety within feasible R&D timelines.

Core Principles & Quantitative Framework

Accelerated aging assumes that the dominant failure mechanisms remain consistent between accelerated and real-time conditions. For polymer encapsulation, hydrolytic degradation is the primary pathway. The Arrhenius equation provides the quantitative basis:

k = A * e^(-Ea/RT)

Where:

- k = degradation rate constant

- A = pre-exponential factor

- Ea = Activation energy (kJ/mol)

- R = Gas constant (8.314 J/mol·K)

- T = Absolute temperature (K)

The acceleration factor (AF) between a real-time storage temperature (Tuse) and an elevated temperature (Tstress) is:

AF = e^[(Ea/R) * (1/Tuse - 1/Tstress)]

Table 1: Calculated Acceleration Factors for Common Implant Conditions

| Assumed Ea (kJ/mol) | Use Condition (T_use) | Stress Condition (T_stress) | Acceleration Factor (AF) | Time at Tstress to simulate 1 year at Tuse |

|---|---|---|---|---|

| 70 | 37°C (310.15 K) | 57°C (330.15 K) | 7.6 | ~48 days |

| 70 | 37°C (310.15 K) | 67°C (340.15 K) | 18.5 | ~20 days |

| 85 | 37°C (310.15 K) | 57°C (330.15 K) | 12.5 | ~29 days |

| 85 | 37°C (310.15 K) | 67°C (340.15 K) | 35.9 | ~10 days |

Note: Ea must be empirically determined for the specific material system. ISO 11907-1 provides guidance. Extrapolation beyond 60°C is often discouraged due to potential for mechanistic shift.

Detailed Experimental Protocols

Protocol 1: Determination of Activation Energy (Ea) for Hydrolytic Degradation

Objective: To empirically determine the Ea for a silicone-polyimide laminate encapsulation system by tracking a key property (e.g., Water Vapor Transmission Rate - WVTR) at multiple elevated temperatures.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Sample Preparation: Fabricate or obtain standardized thin-film discs (e.g., 5 cm diameter) of the encapsulation laminate. Ensure uniform thickness (±5%).

- Conditioning: Dehydrate all samples in a vacuum desiccator (< 0.1 atm) at 40°C for 48 hours. Record initial dry mass (M_initial).

- Aging Setup: Place samples in controlled humidity chambers (e.g., 90% RH ± 2%) maintained at four distinct temperatures: 47°C, 57°C, 67°C, and 77°C. Use saturated salt solutions for RH control.

- Sampling & Measurement: At predetermined intervals (e.g., 24, 48, 96, 168, 336 hours), remove triplicate samples from each condition.

- Blot surface moisture.

- Immediately measure mass (M_wet).

- Return samples to desiccator for final dry mass (Mfinaldry).

- Data Analysis:

- Calculate moisture uptake: %Uptake = [(Mwet - Mfinaldry) / Minitial] * 100.

- Model the initial linear region of uptake vs. √time for each temperature to obtain the uptake rate constant (kT).

- Plot ln(kT) vs. 1/T (in Kelvin). Perform linear regression. The slope = -Ea/R.

- Calculate Ea = -slope * R.

Protocol 2: Full-System Accelerated Aging & Failure Point Analysis

Objective: To subject a complete, functional implantable device (e.g., a sealed pulse generator) to accelerated aging and monitor for electrical and barrier failure.

Materials: Functional implantable devices, impedance analyzer, helium leak tester, environmental chambers.

Methodology:

- Baseline Testing: For each device (n≥10 per group), record:

- Hermeticity via fine helium leak test (per ASTM F2391).

- Key electrical parameters (impedance, battery voltage, function output).

- Device mass.

- Aging Matrix: Place devices in phosphate-buffered saline (PBS, pH 7.4 ± 0.1) at 57°C and 87°C. Include a control group at 37°C for real-time correlation.

- In-Situ Monitoring: Use wired or wireless systems to log electrical parameters of submerged devices continuously or at frequent intervals.

- Destructive Endpoint Analysis: At scheduled time points (e.g., 4, 8, 12, 24 weeks at 87°C, correlating to multi-year equivalents), remove devices.

- Perform electrical function test.

- Conduct leak test.

- Perform destructive physical analysis (DPA): section device, inspect for corrosion, measure adhesive bond strength, analyze polymer chemistry via FTIR or DSC for changes in crystallinity/chain scission.

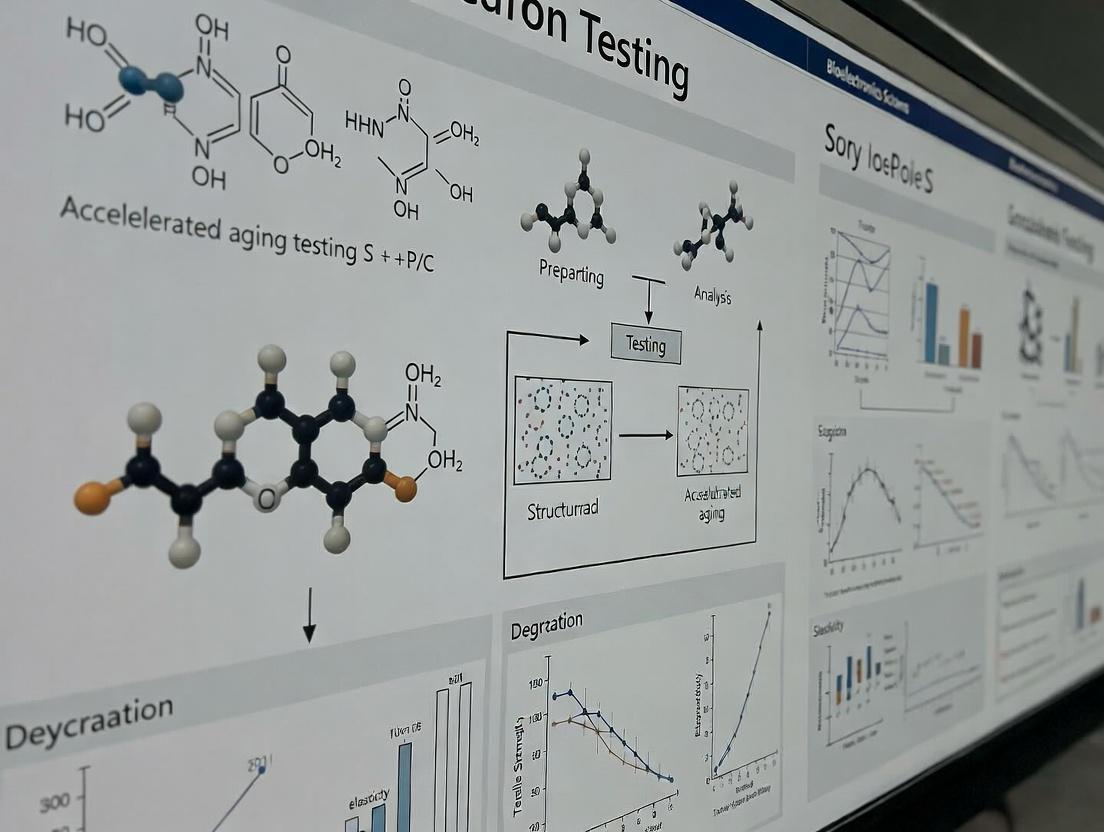

Visualizations

Diagram Title: Accelerated Aging Prediction Workflow (98 chars)

Diagram Title: Material Degradation Pathway to Failure (99 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Encapsulation Aging Studies

| Item / Reagent | Function / Relevance | Key Considerations |

|---|---|---|

| Medical Grade Silicone Elastomers (e.g., Nusil, Dow Silicones) | Primary encapsulation material; flexible, biocompatible barrier. | Lot consistency, purity (low leachables), cure kinetics. |

| Polyimide Substrates & Tapes | Provides mechanical support and electrical insulation in hybrid laminates. | Adhesion promotion, hydrolytic stability grade, thickness. |

| Phosphate-Buffered Saline (PBS), pH 7.4 | Simulates physiological ionic environment for in vitro aging. | Sterility, absence of microbial growth inhibitors that could skew chemistry. |

| Controlled Humidity Chambers | Enables precise relative humidity (RH) control for dry-state aging studies. | Use of saturated salt solutions (e.g., K₂SO₄ for 97% RH) for cost-effectiveness. |

| Water Vapor Transmission Rate (WVTR) Analyzer (e.g., gravimetric, coulometric) | Quantifies the primary barrier property of encapsulation films. | Sensitivity (needs to reach <10⁻³ g/m²/day for implants), temperature control. |

| Fine Helium Leak Detector | Measures hermetic seal integrity of final device packages per ASTM standards. | Detection limit must be ≤ 1x10⁻⁸ atm·cc/sec He. |

| Electrochemical Impedance Spectroscopy (EIS) Setup | Monitors insulation resistance and detects early-stage moisture ingress in situ. | Use of biocompatible electrodes (Pt, IrOx), relevant frequency range (0.1 Hz - 1 MHz). |

| Differential Scanning Calorimetry (DSC) | Analyzes polymer thermal transitions (Tg, Tm, crystallinity) post-aging to assess chain scission/crosslinking. | Small sample size (5-10 mg), need for hermetically sealed pans to contain moisture. |

Application Notes

Within the thesis on accelerated aging testing for implantable encapsulation materials, three primary regulatory and consensus standards form the framework for validating shelf-life claims. These documents guide the design, execution, and interpretation of accelerated aging protocols, ensuring data integrity and regulatory acceptance.

1. ASTM F1980-21: Standard Guide for Accelerated Aging of Sterile Medical Device Packages This is the foundational methodological guide. It details the use of the Arrhenius model for simulating real-time degradation via elevated temperature. It is directly applicable to packaging systems but is extensively used for the devices/materials themselves when assessing shelf-life. Key principles include:

- Q10 Approach: Establishes the acceleration factor (Q10), typically 2.0 for many polymers, though a conservative 1.8 may be used if material-specific data is unavailable.

- Real-Time Correlation: Mandates concurrent real-time aging studies to validate the accelerated model's predictions.

- Aging Temperature Cap: Recommends a maximum aging temperature no greater than 15°C below the material's glass transition or melting point to avoid inducing non-representative degradation pathways.

2. ISO 11985:2023 Ophthalmic optics — Contact lenses — Ageing by exposure to light While specific to contact lenses, this standard is critically instructive for encapsulation materials susceptible to photodegradation. It provides a complementary model to thermal aging for materials that will be transparent or exposed to light in vivo. It details:

- Light Source Specifications: Use of xenon-arc lamps simulating full-spectrum sunlight.

- Exposure Cycles: Defined cycles of light and dark periods, often with controlled temperature and humidity.

- Application to Implants: The protocol can be adapted for subcutaneous or intraocular implants where photochemical aging is a relevant failure mode alongside thermal- oxidative aging.

3. FDA Guidance: Container Closure Systems for Packaging Human Drugs and Biologics & Various Device Guidance Documents The FDA does not prescribe a single protocol but provides the regulatory expectations for shelf-life claims across multiple guidance documents. Core requirements include:

- Stability-Indicating Methods: Analytical methods must distinguish degradation products from the parent material.

- Statistical Confidence: Data must support the claimed shelf life with an acceptable confidence level (e.g., 95%).

- Worst-Case Selection: Testing must represent worst-case scenarios for storage, shipping, and use.

- Link to Performance: The tested critical-to-quality attributes (e.g., tensile strength, permeability, elongation) must be directly linked to the device's safety and performance.

Comparative Data Summary

| Document | Primary Scope | Key Quantitative Parameter | Typical Test Condition Range | Model Validation Requirement |

|---|---|---|---|---|

| ASTM F1980-21 | Medical Device/Package Aging | Acceleration Factor (Q10 = 1.8 - 2.2) | Temp: 50°C - 70°CHumidity: As required | Mandatory real-time aging correlation |

| ISO 11985:2023 | Photodegradation of Polymers | Light Irradiance (W/m²) & Total Dose (J/m²) | Xenon arc, 0.5 - 1.1 W/m² @ 420 nmControlled Temp (e.g., 35°C) | Correlation to real-time indoor/outdoor exposure |

| FDA Guidance | Drug/Device Shelf-Life Claims | Confidence Interval (e.g., 95%) & Acceptance Criteria | Condition-specific; based on ICH Q1A(R2) principles | Statistically justifiable projection from data |

Experimental Protocols

Protocol 1: Combined Thermal-Oxidative Accelerated Aging per ASTM F1980 Objective: To predict the 5-year shelf-life of a silicone-based encapsulation material.

- Determine Q10: Via literature review or preliminary DSC/TGA. Use Q10=2.0 for silicone.

- Calculate Aging Duration: For a 5-year (1825 days) claim and an aging temperature of 55°C (assuming 25°C ambient): Acceleration Factor (AF) = Q10^((Taging - Troom)/10) = 2.0^((55-25)/10) = 2.0^3 = 8. Required aging time = 1825 days / 8 = 228 days.

- Prepare Samples: Divide into three groups: A (Time Zero controls), B (Accelerated aging), C (Real-time aging at 25°C).

- Conditioning: Place Group B in an environmental chamber at 55°C ± 2°C and 50% ± 5% RH. Use forced-air ovens for uniformity.

- Interim Time Points: Remove samples at intervals (e.g., 1, 3, 6 months) for testing.

- Testing: Perform stability-indicating tests: tensile strength (ASTM D412), elongation at break, durometer hardness (ASTM D2240), and permeability assay.

- Validation: Compare Group B (accelerated) endpoint data to Group C (real-time) data at the correlated time point to validate the model.

Protocol 2: Supplemental Photodegradation Aging per ISO 11985 (Adapted) Objective: To assess light-induced degradation of a polyurethane encapsulation for an implantable sensor.

- Sample Mounting: Securely mount samples in exposure frames, ensuring uniform irradiance.

- Exposure Parameters: Use a xenon-arc light source with an appropriate daylight filter. Set irradiance to 0.8 W/m² measured at 420 nm. Maintain chamber temperature at 35°C ± 2°C and relative humidity at 50% ± 5%.

- Cycle: Employ a repeating cycle of 4 hours light followed by 2 hours dark (no irradiance, environmental controls maintained).

- Dosimetry: Continuously monitor and totalize the radiant exposure (J/m²).

- Duration: Calculate exposure time to simulate, e.g., 2 years of ambient indoor light exposure. Interim pulls at defined radiant exposure doses.

- Testing: Assess for yellowing (colorimetry), surface cracking (SEM), and changes in molecular weight (GPC).

Visualizations

Shelf-Life Validation Workflow for Encapsulation Materials

Arrhenius Model Calculation & Temperature Check

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Solution | Function in Accelerated Aging Research |

|---|---|

| Environmental Chamber | Precisely controls temperature (±0.5°C) and relative humidity (±2% RH) for ASTM F1980-compliant thermal-oxidative aging. |

| Xenon-Arc Weatherometer | Provides full-spectrum simulated sunlight with controlled irradiance, temperature, and humidity for photodegradation studies per ISO 11985. |

| Tensile Tester | Quantifies mechanical integrity (ultimate tensile strength, elongation at break) of aged vs. control encapsulation materials. |

| Gel Permeation Chromatograph (GPC) | Measures changes in polymer molecular weight distribution, a key indicator of chain scission or crosslinking degradation. |

| Fourier-Transform Infrared Spectrometer (FTIR) | Identifies chemical bond changes (e.g., oxidation, hydrolysis) on the surface and in the bulk of aged materials. |

| Stability-Indicating Assay | A custom analytical method (e.g., HPLC, permeability test) specifically designed to monitor the specific degradation products of the encapsulated active. |

| Data Loggers | Independent sensors placed within chambers to continuously verify and document time, temperature, and humidity conditions for regulatory audits. |

Within the critical field of implantable encapsulation materials research, predicting long-term material stability is paramount. Accelerated aging testing, a cornerstone methodology, relies fundamentally on the principles of chemical kinetics and the Arrhenius equation. This application note details the theoretical underpinnings, practical protocols, and key reagents for applying these concepts to model and predict the degradation kinetics of polymeric encapsulation barriers under accelerated conditions, thereby ensuring device safety and efficacy over multi-year implantation periods.

Core Theoretical Framework

The rate of a chemical reaction, including the degradation processes (e.g., hydrolysis, oxidation) in polymers, is temperature-dependent. The Arrhenius equation quantifies this relationship:

k = A e^(-Ea/RT)

Where:

- k = reaction rate constant

- A = pre-exponential factor (frequency factor)

- Ea = activation energy (J/mol)

- R = universal gas constant (8.314 J/mol·K)

- T = absolute temperature (K)

In accelerated aging studies for medical implants, materials are subjected to elevated temperatures to accelerate degradation mechanisms. Data from these conditions are extrapolated to predict real-time (e.g., 37°C body temperature) performance using the linearized form:

ln(k) = ln(A) - (Ea/R)(1/T)

A plot of ln(k) versus 1/T yields a straight line with a slope of -Ea/R, enabling the calculation of the activation energy and the prediction of the rate constant at the use temperature.

Key Quantitative Data in Encapsulation Aging

The following table summarizes typical activation energies for common degradation pathways relevant to implantable encapsulation materials, such as polyurethanes, silicones, and epoxies.

Table 1: Typical Activation Energies for Polymer Degradation Pathways

| Degradation Pathway | Typical Polymer Class | Activation Energy (Ea) Range (kJ/mol) | Key Notes for Encapsulation |

|---|---|---|---|

| Ester Hydrolysis | Poly(lactic-co-glycolic acid) (PLGA), Polyurethanes | 50 - 85 | Highly dependent on pH and local moisture permeability. Critical for bioresorbable coatings. |

| Oxidative Chain Scission | Polyethylene, Polypropylene | 80 - 120 | Relevant for materials exposed to inflammatory oxidative stress in vivo. |

| Siloxane Oxidation | Polydimethylsiloxane (Silicone) | 100 - 150 | Primary long-term aging mechanism for silicone elastomers. |

| Crosslinking (Post-Cure) | Epoxy resins, Polyurethanes | 70 - 110 | Can increase modulus and brittleness over time, leading to crack formation. |

Experimental Protocol: Determining Ea for Hydrolytic Degradation

This protocol outlines a method to determine the activation energy for the hydrolysis of a polyester-based encapsulation material.

Title: Accelerated Hydrolytic Aging of Polyester Films

Objective: To determine the activation energy (Ea) for the hydrolysis reaction of a model polyester film by measuring property loss (e.g., molecular weight) at multiple elevated temperatures.

Materials & Reagents (Scientist's Toolkit):

Table 2: Key Research Reagent Solutions & Materials

| Item | Function/Description |

|---|---|

| Polyester Test Films | Model encapsulation material, precisely cast to a standardized thickness (e.g., 100 ± 10 µm). |

| Phosphate Buffered Saline (PBS), 0.01M, pH 7.4 | Simulates physiological pH and ionic strength for hydrolysis. |

| pH-Stat Apparatus | For precise maintenance of pH during aging, or for monitoring acid release rate. |

| Gel Permeation Chromatography (GPC) System | For measuring the decline in number-average molecular weight (Mn) over time, the primary degradation metric. |

| Hermetic Aging Vessels | Sealed glass vials or reactors to contain samples in PBS at controlled temperatures. |

| Controlled-Temperature Ovens/Water Baths | For maintaining accurate accelerated aging temperatures (e.g., 50°C, 60°C, 70°C, 80°C). |

Procedure:

- Sample Preparation: Cut polyester films into identical discs (n≥5 per time point per temperature). Pre-weigh and measure initial thickness. Characterize initial molecular weight (Mn₀) via GPC.

- Accelerated Aging Setup: Place individual samples in aging vessels filled with excess PBS (to ensure sink conditions). Purge headspace with nitrogen to minimize oxidation. Seal hermetically.

- Temperature Array Incubation: Place sets of vessels in ovens pre-set at a minimum of four elevated temperatures (e.g., 50, 60, 70, 80°C). Include one set at the use temperature (37°C) for model validation.

- Sampling: At predetermined time intervals, remove replicate vessels (n=3-5) from each temperature. Rinse samples, dry under vacuum, and store in a desiccator until analysis.

- Analysis: Determine molecular weight (Mn_t) of aged samples via GPC.

- Data Modeling: Assume hydrolysis follows pseudo-first-order kinetics. For each temperature, plot ln(Mn_t/Mn₀) vs. time. The slope of the linear region is the apparent rate constant, k, for that temperature.

- Arrhenius Plot: Plot ln(k) versus 1/T (where T is in Kelvin) for all accelerated temperatures. Perform linear regression.

- Calculation: Calculate Ea = -Slope * R. Use the fitted equation to extrapolate k at 37°C and predict the time for 50% molecular weight loss in vivo.

Conceptual Diagrams

Diagram Title: Accelerated Aging Prediction Workflow

Diagram Title: Energy Diagram for Polymer Hydrolysis

Application Notes

The development of next-generation implantable medical devices—from pacemakers and neurostimulators to drug-eluting implants and biosensors—is contingent on advanced encapsulation materials. These materials must provide long-term, reliable protection for sensitive electronics and/or bioactive agents within the aggressive physiological environment. This document, framed within a broader thesis on accelerated aging methodologies, details the critical triad of material properties under evaluation: Barrier Function, Mechanical Integrity, and Biocompatibility. The protocols herein are designed for researchers to systematically assess these properties under simulated in vivo and accelerated aging conditions.

Barrier Function is the primary role of encapsulation, preventing the ingress of water, ions (Na⁺, Cl⁻, K⁺), and biological fluids that can cause device failure via corrosion, electrical shorting, or drug instability. Evaluation moves beyond simple water vapor transmission rates to include specific ion permeability under physiological conditions.

Mechanical Integrity ensures the encapsulation maintains its structural and protective role despite constant mechanical stress in vivo, including flexing, compression, and tensile forces from tissue movement. Properties like modulus, fracture toughness, and adhesion strength are monitored for degradation over time.

Biocompatibility assesses the local and systemic host response. It is not merely the inertness of the virgin material, but the biological response to its degradation products and altered surface morphology after aging. Chronic inflammation and fibrous encapsulation can impair device function.

Accelerated aging testing (AAT), utilizing elevated temperature and humidity per ASTM F1980, is employed to predict long-term performance. However, correlating accelerated conditions to real-time aging requires careful analysis of these three interdependent properties, as degradation in one often precipitates failure in another.

Protocols & Experimental Methodologies

Protocol 1: Quantitative Barrier Function Assessment via Electrochemical Impedance Spectroscopy (EIS)

Objective: To measure the ionic resistivity and defect density of thin-film encapsulation coatings on conductive substrates under simulated physiological saline (0.9% NaCl, 37°C) before and after accelerated aging.

Materials & Setup:

- Test Samples: Encapsulation material coated onto planar noble metal (e.g., platinum, gold) electrodes.

- Electrolyte: Phosphate Buffered Saline (PBS, pH 7.4) or 0.9% NaCl.

- Equipment: Potentiostat/Galvanostat with EIS capability, 3-electrode cell (sample as working electrode, Pt mesh as counter electrode, Ag/AgCl reference electrode), environmental chamber for temperature control.

- Aging: Samples aged per ASTM F1980 (e.g., 60°C, 80% RH for intervals equivalent to 1, 3, 6 months in vivo).

Procedure:

- Baseline Measurement: Immerse pristine sample in 37°C PBS. Apply a sinusoidal voltage perturbation (10 mV amplitude) over a frequency range from 100 kHz to 0.1 Hz at the open circuit potential.

- Aging: Subject samples to controlled accelerated aging conditions.

- Post-Aging Measurement: Repeat step 1 after each aging interval.

- Data Analysis: Fit the low-frequency impedance modulus (e.g., at 0.1 Hz, |Z|₀.₁Hz) or the impedance of the coating derived from a Randles circuit model. Calculate the coating's ionic resistivity (ρ) from the pore resistance (Rpo).

Quantitative Data Output: Table 1: EIS Barrier Function Data for Polymer Encapsulant X After Accelerated Aging (Equivalent to 12 months in vivo).

| Aging Interval (Equiv. Months) | Low-Freq Impedance | Z | ₀.₁Hz (Ω·cm²) | Pore Resistance Rpo (MΩ·cm²) | Calculated Ionic Resistivity (Ω·cm) | Visual Defect Density (#/cm²) |

|---|---|---|---|---|---|---|

| 0 (Pristine) | 5.2 × 10⁸ | 4.8 × 10⁸ | 1.2 × 10¹² | 0 | ||

| 3 | 3.1 × 10⁸ | 2.7 × 10⁸ | 6.8 × 10¹¹ | < 5 | ||

| 6 | 4.5 × 10⁷ | 3.9 × 10⁷ | 9.8 × 10¹⁰ | 15 | ||

| 12 | 1.8 × 10⁶ | 1.5 × 10⁶ | 3.8 × 10⁹ | 120 |

EIS Workflow for Barrier Assessment

Protocol 2: Mechanical Integrity Evaluation via Nanoindentation and Peel Adhesion Testing

Objective: To characterize the time-dependent evolution of key mechanical properties: hardness, reduced modulus, and interfacial adhesion strength post-aging.

Part A: Nanoindentation for Bulk Film Properties

- Equipment: Nanoindenter with Berkovich tip.

- Procedure: Perform grid indents (e.g., 5x5) on encapsulated surfaces. Use the Oliver-Pharr method to analyze load-displacement curves. Report hardness (H) and reduced modulus (Er).

- Aging Correlation: Monitor for softening (decrease in H, Er) due to plasticization by absorbed water or hardening due to continued cross-linking.

Part B: 90-Degree Peel Test for Adhesion Strength

- Sample Preparation: Fabricate samples per ASTM D6862: encapsulant laminated onto a rigid substrate (e.g., silicon, titanium) with a pre-defined non-adhesive tab.

- Equipment: Universal tensile testing machine.

- Procedure: Peel the encapsulant at a 90-degree angle at a constant crosshead speed (e.g., 25 mm/min). Record peel force (F) over a stable peeling region.

- Calculation: Adhesion energy (G, J/m²) = 2F / w, where w is the width of the peel strip.

Quantitative Data Output: Table 2: Mechanical Property Degradation of Silicone-Polyurethane Hybrid Encapsulant After Accelerated Aging.

| Aging Condition (60°C, 80% RH) | Hardness (H) [MPa] | Reduced Modulus (Er) [GPa] | Peel Adhesion Strength [N/cm] | Failure Mode |

|---|---|---|---|---|

| 0 days (Pristine) | 25.4 ± 1.2 | 2.8 ± 0.2 | 15.3 ± 1.5 | Cohesive (within encapsulant) |

| 14 days | 22.1 ± 1.5 | 2.5 ± 0.3 | 14.1 ± 1.8 | Mixed Cohesive/Adhesive |

| 28 days | 18.7 ± 2.1 | 2.1 ± 0.2 | 9.8 ± 2.2 | Adhesive (at substrate interface) |

| 56 days | 15.3 ± 2.8 | 1.7 ± 0.4 | 5.2 ± 1.7 | Complete Adhesive Failure |

Mechanical Degradation Pathways

Protocol 3: In Vitro Biocompatibility Assessment Post-Aging (ISO 10993-5/-12)

Objective: To evaluate the cytotoxic and inflammatory potential of encapsulation materials after leaching in simulated physiological fluids post-aging.

Part A: Direct Contact & Extract Elution Cytotoxicity Test

- Sample Preparation & Aging: Sterilize material samples (e.g., discs). Subject a subset to accelerated aging. Prepare extracts by incubating aged and non-aged samples in cell culture medium (e.g., DMEM) for 24h at 37°C.

- Cell Culture: Use L929 mouse fibroblast cells or human-relevant cell lines (e.g., THP-1 for monocytes).

- Assay: Expose cells to extracts or place materials in direct contact. After 24-48h, assess viability via MTT or AlamarBlue assay. Report viability relative to negative control.

Part B: Assessment of Inflammatory Response (THP-1 Monocyte Model)

- Differentiation: Differentiate THP-1 monocytes into macrophage-like cells using PMA.

- Exposure: Expose macrophages to material extracts (from Part A).

- Analysis: Quantify pro-inflammatory cytokines (IL-1β, IL-6, TNF-α) in supernatant via ELISA after 24h exposure.

Quantitative Data Output: Table 3: Biocompatibility Profile of Aged vs. Pristine Polyimide Film.

| Test Article | Cell Viability (% of Control) | IL-1β Release (pg/mL) | TNF-α Release (pg/mL) | Observation (Activation State) |

|---|---|---|---|---|

| Negative Control (HDPE) | 100 ± 5 | 15 ± 3 | 20 ± 4 | Non-activated, resting |

| Pristine Polyimide | 98 ± 4 | 25 ± 5 | 30 ± 6 | Mild, non-significant activation |

| Polyimide (Aged, 56 days) | 72 ± 8* | 185 ± 22* | 210 ± 25* | Significant pro-inflammatory activation |

| Positive Control (Latex) | 45 ± 10* | 450 ± 50* | 500 ± 55* | Severe activation |

( indicates statistically significant difference vs. Negative Control, p<0.01)*

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Encapsulation Material Testing.

| Item Name / Kit | Function / Application | Example Vendor(s) |

|---|---|---|

| Potentiostat/Galvanostat with EIS | Measures electrochemical impedance for quantitative barrier function assessment. | Metrohm, Biologic, Ganny |

| Nanoindentation System | Measures nanoscale hardness and reduced modulus of thin-film encapsulation materials. | Bruker, KLA, Anton Paar |

| Universal Tensile Tester | Quantifies peel adhesion strength and other macro-mechanical properties. | Instron, MTS, ZwickRoell |

| ISO 10993-12 Compliant Extraction Kit | Provides standardized containers and protocols for preparing material extracts for biocompatibility. | Nusil Technology, MilliporeSigma |

| Multiplex Cytokine ELISA Assay Kit (Human) | Quantifies multiple inflammatory cytokines (IL-1β, IL-6, TNF-α) from cell culture supernatants. | R&D Systems, BioLegend, Abcam |

| AlamarBlue Cell Viability Reagent | Fluorescent/colorimetric indicator for measuring in vitro cytotoxicity per ISO 10993-5. | Thermo Fisher Scientific |

| ASTM F1980 Compliant Accelerated Aging Chamber | Provides controlled elevated temperature and humidity for predictive aging studies. | CTS, Thermotron, ESPEC |

| Simulated Body Fluid (SBF) Solution * | Ionic solution mimicking human blood plasma for in vitro degradation and barrier testing. | Bioreliance, Sigma-Aldrich |

Within the broader thesis on accelerated aging testing for implantable encapsulation materials, this document addresses the central challenge of correlating short-term in-vitro degradation data with long-term in-vivo performance. The goal is to establish predictive models for material lifetimes, particularly for drug-eluting implants and bioelectronic interfaces, where encapsulation integrity over decades is critical.

Table 1: Primary Discrepancies Between In-Vitro and In-Vivo Environments

| Factor | Standard In-Vitro Condition | Typical In-Vivo Environment | Impact on Correlation |

|---|---|---|---|

| Solution Chemistry | Static PBS, pH 7.4, fixed ions | Dynamic interstitial fluid, variable pH (7.0-7.4), enzymes, proteins | Protein adsorption alters degradation kinetics; ions catalyze/passivate reactions. |

| Mechanical Stress | Often quiescent or simple cyclic strain. | Complex multiaxial stress (pulsatile, muscle movement). | Stress-corrosion cracking and fatigue not captured in static tests. |

| Inflammatory Response | Absent. | Foreign body response (FBR): macrophage adhesion, fusion, cytokine release. | Giant cells and reactive oxygen species (ROS) aggressively degrade materials. |

| Sample Retrieval & Analysis | Controlled, non-destructive sampling possible. | Requires sacrifice, explant; surface altered during retrieval. | Limits longitudinal data points per subject; introduces artifact risk. |

Table 2: Reported Acceleration Factors for Common Encapsulation Polymers

| Material | Standard In-Vivo Degradation Time (Yrs) | Common Accelerated In-Vitro Condition | Reported Acceleration Factor | Key Correlation Limitation |

|---|---|---|---|---|

| Polyimide | >10 (Insulation failure) | 87°C, PBS (hydrolytic) | ~10-20x | Neglects oxidative stress from FBR. |

| PDMS | 5-25 (Creep, calcification) | 70°C, H₂O₂ Solution (oxidative) | ~15-30x | Difficulty replicating calcification process. |

| Parylene-C | >20 (Delamination) | 120°C, High Humidity (hydrolytic) | ~50-100x | Does not simulate interfacial bio-adhesion. |

| Silicone Epoxy | 10-15 (Water uptake) | 85°C/85% RH (temperature/humidity bias) | ~20-50x | Immune cell-mediated degradation not accelerated. |

Detailed Experimental Protocols

Protocol 3.1: Multi-Stressor In-Vitro Accelerated Aging

Objective: To simulate combined hydrolytic, oxidative, and mechanical stress in-vitro. Materials: Test chambers, orbital shaker with temperature control, PBS (1x), Hydrogen Peroxide (H₂O₂, 0.1-1.0M), loading fixtures. Procedure:

- Prepare test samples of encapsulation material per ISO 10993-12.

- Prepare aging solutions: (A) PBS (control), (B) PBS + 0.3M H₂O₂ (oxidative).

- Place samples in solutions within sealed vials. Mount vials on orbital shaker platform to apply mild fluid shear stress.

- Place entire assembly in temperature-controlled oven at 70°C, 80°C, and 90°C (for Arrhenius analysis).

- Remove sample subsets at predetermined intervals (e.g., 1, 2, 4, 8 weeks).

- Perform characterization: Mass loss, water uptake, FTIR for chemical change, impedance spectroscopy (for coatings).

- Extract degradation rate constants (k) at each temperature. Use Arrhenius equation (ln(k) vs. 1/T) to extrapolate rate at 37°C.

Protocol 3.2: Ex-Vivo Analysis of Explanted Encapsulation Materials

Objective: To characterize materials retrieved from an in-vivo model and compare degradation modes to in-vitro predictions. Materials: Explanted devices, histological fixative, scanning electron microscope (SEM), X-ray photoelectron spectroscopy (XPS). Procedure:

- Explant: Sacrifice animal model at endpoint. Gently explant device with surrounding tissue intact.

- Gross Examination: Photograph device and tissue. Note adhesion, discoloration, visible defects.

- Tissue-Material Interface Processing: Fix tissue-device block in 4% PFA. Dehydrate and embed in resin (e.g., PMMA). Microtome cross-sections.

- Material Surface Analysis:

- SEM/EDS: Image surface morphology and analyze elemental composition of deposits.

- XPS: Analyze top 10 nm of surface chemistry for protein signatures, oxidation states.

- Correlative Analysis: Map degradation features (cracks, pits, biofilm) from ex-vivo samples to features seen in in-vitro samples subjected to Protocol 3.1.

Protocol 3.3: In-Vitro Foreign Body Response Simulation

Objective: To incorporate immune system components into in-vitro testing. Materials: Primary human macrophages or cell line (e.g., THP-1), cell culture media, LPS/IFN-γ for M1 polarization, IL-4/IL-13 for M2 polarization, fluorescent ROS probe (e.g., DCFDA). Procedure:

- Sterilize material samples (UV or ethanol).

- Seed macrophages onto material surfaces at high density (e.g., 50,000 cells/cm²).

- Polarize cells towards pro-inflammatory M1 phenotype using LPS (100 ng/mL) and IFN-γ (20 ng/mL) for 48 hours.

- Maintain co-culture for up to 14 days, refreshing media and cytokines every 2-3 days.

- Monitor ROS production: Incubate with DCFDA (10 µM) for 30 min, image fluorescence.

- At endpoint, analyze material surface via SEM and culture supernatant for cytokine levels (ELISA) to quantify inflammatory potency.

- Compare surface degradation to samples aged in H₂O₂ solutions alone.

Visualization: Pathways and Workflows

Title: The In-Vivo / In-Vitro Correlation Challenge Path

Title: Multi-Stressor Accelerated Aging Workflow

Title: Key Foreign Body Response Pathway Affecting Materials

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Correlation Studies

| Item / Reagent | Function / Role | Key Consideration for Correlation |

|---|---|---|

| Controlled-Temperature/Humidity Ovens | Provides thermal acceleration for hydrolytic degradation (Arrhenius model). | Must have precise RH control. High T may induce non-physical degradation modes. |

| Hydrogen Peroxide (H₂O₂) Solutions | Chemical oxidant to simulate reactive oxygen species (ROS) from immune cells. | Concentration (0.1-3%) must be calibrated; high levels can cause unrealistic blistering. |

| Simulated Body Fluid (SBF) | Ionic solution mimicking blood plasma for more realistic mineral deposition. | Better than PBS for predicting bioactivity and certain surface changes. |

| Macrophage Cell Lines (e.g., THP-1) | In-vitro model for the foreign body response and immune-mediated degradation. | Requires proper differentiation (PMA) and polarization (cytokines) to be relevant. |

| Electrochemical Impedance Spectroscopy (EIS) Setup | Non-destructive tracking of barrier property degradation of thin films in-situ. | Critical for functional coatings; can be used in both in-vitro and in-vivo models. |

| Multi-Axis Mechanical Testers | Applies cyclic flexural or tensile stress to simulate in-vivo mechanical loading. | Matching the correct strain amplitude and frequency is challenging but crucial. |

| X-ray Photoelectron Spectroscopy (XPS) | Surface-sensitive analysis (<10 nm) to detect oxidation states and protein fouling. | Gold standard for comparing surface chemistry changes from in-vitro vs. ex-vivo samples. |

| Fluorescent ROS Probes (e.g., DCFDA) | Quantifies reactive oxygen species production by cells on material surfaces. | Directly links immune cell activity to a quantifiable chemical stressor. |

Executing the Test: Standard Protocols, Environmental Stressors, and Real-Time Parallels for Accurate Aging Studies

Within the accelerated aging research for implantable encapsulation materials, the construction of a test matrix is a critical, hypothesis-driven exercise. It is not an arbitrary selection of conditions but a deliberate design to probe failure modes, predict service life, and understand degradation kinetics of materials such as silicones, polyurethanes, parylene, and epoxy resins used in drug-eluting implants, neurostimulators, and pacemakers. This protocol details the methodology for selecting and applying stress factors (temperature, humidity, pH, mechanical load) to simulate and accelerate real-world aging in a controlled laboratory environment.

Rationale for Stress Factor Selection

Accelerated aging relies on the principle of accelerating degradation mechanisms relevant to the implant's intended environment (e.g., subcutaneous, intravascular, cerebrospinal fluid). The Arrhenius model is fundamental for temperature acceleration, while humidity, chemical (pH), and mechanical stresses are selected based on the specific failure modes of interest, such as hydrogel swelling, polymer hydrolysis, drug diffusion rate changes, or adhesive delamination.

Core Stress Factors: Quantitative Ranges & Justification

Table 1: Primary Climatic Stress Factors & Typical Ranges

| Stress Factor | Typical Accelerated Test Range | Real-World Physiological Baseline | Acceleration Justification & Material Impact |

|---|---|---|---|

| Temperature | 40°C to 80°C | ~37°C (body temp) | Arrhenius kinetics; increases molecular mobility, reaction rates (hydrolysis, oxidation). Upper limit avoids inducing non-physical phase transitions. |

| Relative Humidity (RH) | 60% to 95% RH | Variable (subcutaneous ~80-100%) | Accelerates hydrolytic degradation, moisture ingress, and swelling. Critical for moisture-sensitive polymers (e.g., polyesters). |

| pH | 2.0 (acidic) to 9.0 (alkaline) | ~7.4 (physiological) | Probes chemical resistance to inflammatory response or metabolic byproducts. Can catalyze specific hydrolysis reactions. |

| Mechanical Load | Static: 100-500 kPaCyclic: 1-10 Hz, ±10-20% strain | Variable by site (e.g., cardiac pulsatile, joint load) | Accelerates fatigue, crack propagation, stress relaxation, and adhesion failure at material interfaces. |

Table 2: Example Test Matrix for a Silicone-based Drug Encapsulant

| Test Cell | Temperature | Humidity | pH Environment | Mechanical Stress | Duration (Planned) | Key Performance Indicators (KPIs) |

|---|---|---|---|---|---|---|

| A1 (Baseline Accelerated) | 70°C | 20% RH (dry) | N/A (dry air) | None | 0, 1, 3, 6 months | Mass, modulus, FTIR (oxidation) |

| A2 (Hydrolytic) | 70°C | 95% RH | Condensed water | None | 0, 1, 3, 6 months | Mass change, water uptake, OOTR |

| B1 (Chemical) | 50°C | Immersed | pH 7.4 PBS | None | 0, 2, 4, 8 weeks | Drug release kinetics, surface morphology |

| B2 (Chemical Acidic) | 50°C | Immersed | pH 2.0 buffer | None | 0, 2, 4, 8 weeks | Mass loss, byproduct analysis |

| C1 (Mechanical) | 37°C | 90% RH | N/A | Static Compression (200 kPa) | 0, 1, 4 weeks | Creep, permanent set |

| C2 (Mechanical Fatigue) | 37°C | 90% RH | N/A | Cyclic Strain (2 Hz, ±15%) | 0, 50k, 200k cycles | Crack initiation, fatigue life |

Detailed Experimental Protocols

Protocol 4.1: Constructing a Temperature-Humidity Matrix for Hydrolytic Aging

Objective: To determine the activation energy for hydrolytic degradation of a polyester-polyurethane encapsulant. Materials: See "Scientist's Toolkit" below. Procedure:

- Sample Preparation: Prepare 30 identical film samples (e.g., 50mm x 50mm x 0.5mm). Measure initial mass (M₀), thickness, and perform FTIR/DSC baseline.

- Matrix Definition: Create a 3x2 matrix: Temperatures (50°C, 60°C, 70°C) and RH levels (75% RH, 95% RH). Include 37°C/95% RH as a real-time control.

- Environmental Exposure: Place samples in controlled environmental chambers (e.g., humidity ovens). Use saturated salt solutions for RH validation within chambers.

- Sampling Schedule: Remove triplicate samples from each condition at intervals (e.g., 1, 2, 4, 8, 12 weeks).

- Analysis:

- Gravimetric Analysis: Pat dry, measure wet mass (Mw), then dry to constant mass (Md). Calculate Water Uptake (%) = [(Mw - Md)/M_d] * 100.

- Molecular Weight: Use GPC on dried samples to track Mn and Mw reduction.

- Mechanical Testing: Perform tensile tests per ASTM D412.

- Data Modeling: Fit molecular weight decay at each temperature to a kinetic model (e.g., first-order). Use Arrhenius plot (ln(k) vs. 1/T) to calculate activation energy (Eₐ) for hydrolysis.

Protocol 4.2: Combined Chemical (pH) and Mechanical Stress Testing

Objective: To evaluate the synergistic effect of pH and dynamic loading on a silicone adhesive bond. Materials: See "Scientist's Toolkit" below. Procedure:

- Bonded Sample Fabrication: Create lap-shear or peel test specimens per ASTM D3163 or D903, bonding the encapsulant to a representative substrate (e.g., titanium, glass).

- Environmental Pre-conditioning: Immerse subgroups of samples in three buffers: pH 2.0, pH 7.4, pH 9.0. Hold at 50°C for 48 hours.

- In-situ Mechanical Testing: Mount pre-conditioned samples (while wet) onto a mechanical tester equipped with an environmental chamber bath.

- Set bath to 37°C with relevant pH buffer.

- Apply a cyclic tensile load (e.g., 0-10 N at 1 Hz) for a set number of cycles (e.g., 10,000).

- Failure Analysis: Monitor for load drop indicating failure. Post-test, examine failure interface (cohesive vs. adhesive) using optical microscopy or SEM. Compare failure cycles and mode across pH groups.

Visualization: Test Matrix Design Logic

(Diagram Title: Accelerated Test Matrix Design Workflow)

The Scientist's Toolkit: Key Research Reagent Solutions

| Item Name / Category | Function in Encapsulation Aging Studies |

|---|---|

| Programmable Environmental Chambers | Precisely control temperature (±0.5°C) and relative humidity (±2% RH) for long-term stability studies. |

| Saturated Salt Solutions (e.g., NaCl, KCl, KNO₃) | Cost-effective method to generate specific, constant RH levels in desiccators for sub-ambient conditioning. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard physiological immersion medium for simulating bodily fluid exposure. |

| Citrate (pH 2-6) & Borate (pH 8-9) Buffers | Used to probe chemical resistance under acidic (inflammatory) or alkaline conditions. |

| In-situ Mechanical Testers with Bath | Electrostatic or servo-hydraulic systems with environmental baths allow mechanical testing under fluid immersion at controlled temperature/pH. |

| Gel Permeation Chromatography (GPC) System | Measures changes in polymer molecular weight distribution, the gold standard for tracking chain scission (hydrolysis, oxidation). |

| Dynamic Vapor Sorption (DVS) Instrument | Precisely measures moisture uptake and diffusion coefficients of thin films as a function of RH. |

| Oxygen Permeation Analyzer (e.g., OX-TRAN) | Quantifies the oxygen transmission rate (OTR), critical for oxidation-prone materials and drug stability. |

| Adhesion Test Fixtures (Lap Shear, Peel, Blister) | Standardized fixtures for quantifying bond strength between encapsulant and substrate under various stresses. |

This application note presents a standardized protocol for the accelerated aging of three primary encapsulant materials used in implantable medical devices: medical-grade silicone elastomers (e.g., polydimethylsiloxane, PDMS), Parylene-C (poly(monochloro-para-xylylene)), and polyurethane (PU) elastomers. The protocol is designed to simulate long-term in vivo degradation within a controlled laboratory timeframe, supporting material selection and reliability predictions as part of a broader thesis on encapsulation materials research.

Research Rationale & Degradation Mechanisms

Accelerated aging tests apply elevated stress factors (temperature, hydration, chemical) to induce failure modes representative of in vivo performance. Key degradation pathways include:

- Silicone: Hydrolytic cleavage of siloxane bonds, loss of low molecular weight (LMW) silicones (bleed), and calcification.

- Parylene-C: Hydrolytic attack on the chloroalkyl group, leading to chlorine loss and chain scission, exacerbated by microcracks.

- Polyurethane: Hydrolytic or oxidative cleavage of ester/ether soft segments and urethane/urea hard segments, leading to chain scission and loss of mechanical integrity.

Experimental Protocol

Materials Preparation & Sample Fabrication

Research Reagent Solutions & Essential Materials:

| Material/Reagent | Function in Protocol |

|---|---|

| Medical-Grade Silicone Elastomer (e.g., Nusil MED-4211) | Primary test material; forms hermetic, flexible barrier. |

| Parylene-C Dimer (Dix-C) | Precursor for vapor deposition coating; conformal, pinhole-free barrier. |

| Medical Polyurethane (e.g., ChronoFlex AR, Elast-Eon 2A) | Primary test material; offers high tensile strength and biostability. |

| Phosphate Buffered Saline (PBS), 1X, pH 7.4 | Primary immersion medium simulates physiological ionic environment. |

| Simulated Body Fluid (SBF) | Alternative immersion medium for bioactive evaluation (e.g., calcification). |

| Demineralized & Deionized Water (ddH₂O) | Control immersion medium for pure hydrolytic studies. |

| Forced-Air Laboratory Oven | Provides stable, elevated temperature environment for aging. |

| Custom Sealed Vessels (e.g., glass jars with PTFE lids) | Contain samples and immersion medium, prevent evaporation. |

| Tensile Test System (e.g., Instron) | Quantifies post-aging mechanical properties (modulus, strength, elongation). |

| Electrochemical Impedance Spectroscopy (EIS) Setup | Measures electrical barrier property (impedance) of coated samples. |

| FTIR Spectrometer | Identifies chemical bond changes (e.g., Si-O-Si, C-Cl, C=O, N-H). |

Sample Fabrication Protocol:

- Silicone/Polyurethane: Mix per manufacturer instructions. Degas in vacuum desiccator. Pour into ASTM D412-F or D638-V dogbone molds. Cure as specified.

- Parylene-C: Deposit on pre-cleaned, planar substrates (e.g., silicon wafers, metal electrodes) and flat, cured silicone/PU samples. Use a standardized vapor deposition process (Gorham process) to achieve a uniform 5-20 µm coating. Verify thickness via profilometry.

Accelerated Aging Procedure

Protocol for Immersion Aging at Elevated Temperature:

- Baseline Characterization: Measure and record initial mass, dimensions, mechanical properties (for elastomers), and EIS spectra (for coated samples).

- Immersion: Place samples in individual sealed vessels containing 20x sample volume of pre-heated immersion medium (PBS, SBF, or ddH₂O). Ensure complete submersion.

- Incubation: Place vessels in a forced-air oven. The standard accelerated condition is 87°C ± 2°C. Rationale: This temperature accelerates hydrolytic reactions while remaining below water boiling point and material glass transition/softening points.

- Monitoring: Extract triplicate samples per material per time point. Rinse with ddH₂O, blot dry, and characterize.

- Time Points: Recommended intervals: 1, 3, 7, 14, 28, and 56 days.

Post-Aging Characterization Methods

Detailed Methodologies:

- Mass Change & Water Uptake: Weigh samples pre-immersion (W₀), post-extraction (Wwet), and after drying to constant mass at 70°C (Wdry). Calculate mass change (%) and water uptake (%).

- Tensile Testing (ASTM D412/D638): Perform uniaxial tensile tests on dogbone samples at a strain rate of 500 mm/min. Record elastic modulus (at 10-20% strain), ultimate tensile strength (UTS), and elongation at break (%).

- Electrochemical Impedance Spectroscopy (EIS): For Parylene-C coated metal electrodes, perform EIS in PBS at 37°C from 1 MHz to 0.1 Hz at 0 V vs. OCP. Fit data to a coating-capacitance model to extract coating impedance (|Z| at 1 Hz) and defect-related parameters.

- Fourier Transform Infrared (FTIR) Spectroscopy: Use ATR-FTIR in the range 4000-650 cm⁻¹. Monitor specific peak areas/ratios: Silicone (Si-O-Si at ~1010 cm⁻¹), Parylene-C (C-Cl at ~690 cm⁻¹), Polyurethane (C=O stretch at ~1730 cm⁻¹, N-H at ~3320 cm⁻¹).

Data Presentation & Expected Outcomes

Table 1: Representative Post-Aging Property Changes (56 Days at 87°C in PBS)

| Material | Mass Change (%) | Water Uptake (%) | UTS Retention (%) | Elongation at Break Retention (%) | Z | at 1 Hz (Ω) | |

|---|---|---|---|---|---|---|---|

| Medical Silicone | +0.8 to +1.5 | ~1.0 | 85-95 | 80-90 | N/A | ||

| Parylene-C (5µm on Si) | Negligible | N/A | N/A | N/A | 1x10⁸ to 1x10⁹ | ||

| Polyether-based PU | +2.0 to +4.0 | 1.5-3.5 | 70-85 | 60-80 | N/A | ||

| Polycarbonate-based PU | +1.0 to +2.0 | 0.8-1.8 | 90-98 | 85-95 | N/A |

Table 2: Key FTIR Degradation Indicators

| Material | Bond/Vibration | Wavenumber (cm⁻¹) | Change Indicative of Degradation |

|---|---|---|---|

| Silicone | Si-O-Si stretch | ~1010 | Broadening, decrease in peak area |

| Parylene-C | C-Cl stretch | ~690 | Decrease in peak intensity |

| Polyurethane | Urethane C=O | ~1730 | Decrease, shift |

| Polyurethane | Urethane N-H | ~3320 | Broadening, decrease |

Visualization of Workflow and Degradation Pathways

Accelerated Aging Experimental Workflow

Key Degradation Pathways for Three Encapsulants

Within the thesis on accelerated aging for implantable encapsulation materials, real-time aging (RTA) studies represent the indispensable gold standard. While predictive accelerated aging models are essential for development, only parallel, long-term RTA controls can validate their predictive accuracy and uncover unforeseen failure modes. These studies provide the baseline data against which all accelerated protocols are calibrated, ensuring regulatory acceptance and long-term patient safety. This document outlines the protocol for establishing such critical RTA studies alongside accelerated testing regimens.

Experimental Protocol: Parallel Real-Time and Accelerated Aging Study

Objective: To correlate degradation profiles of implantable encapsulation materials (e.g., silicone, polyurethane, parylene) under accelerated conditions with real-time performance, establishing predictive models.

2.1 Materials Preparation & Baseline Characterization

- Materials: Test encapsulation materials (as finished devices or representative coupons).

- Pre-conditioning: Sterilize per intended use (e.g., EtO, gamma irradiation). Record lot numbers and processing history.

- T₀ Testing: Perform full battery of characterization tests on a subset of samples (n≥5) prior to aging. See Table 1.

2.2 Study Arm Allocation & Storage Establish two parallel study arms with matched samples from the same production lots.

- Arm A: Real-Time Aging (RTA).

- Storage Condition: 37°C ± 1°C, in simulated physiological solution (e.g., PBS, pH 7.4 ± 0.1) or 97% RH (for dry-state control).

- Containers: Chemically inert vials (e.g., glass) with headspace minimized or controlled.

- Sample Size: n≥10 per time point per material variant to allow for destructive testing.

- Arm B: Accelerated Aging (AA).

- Storage Condition: Elevated temperature per Arrhenius methodology (e.g., 50°C, 65°C). Environment identical to Arm A (same solution or RH).

- Sample Size: n≥5 per time point per temperature.

2.3 Time Points & Sample Retrieval

- RTA Arm: Retrieve samples at biologically relevant intervals (e.g., 1, 3, 6, 12, 18, 24, 36, 60 months). Longer durations (5-10 years) are ideal.

- AA Arm: Retrieve samples at intervals calculated to theoretically match RTA timepoints based on the assumed activation energy (Ea). Example for an Ea of 0.7 eV is shown in Table 2.

2.4 Post-Aging Analysis Protocol Upon retrieval, samples are rinsed, dried (if appropriate), and analyzed. Tests must be identical for both arms.

- Visual Inspection: Under microscope for cracks, discoloration, delamination.

- Mass Change: Measure dry mass to calculate absorption or degradation.

- Thermal Analysis: DSC for Tg, Tm; TGA for decomposition.

- Mechanical Testing: Tensile test for ultimate strength, elongation, modulus.

- Chemical Analysis: FTIR for chemical structure changes, SEM-EDS for surface morphology/elemental analysis.

- Functional Testing: For encapsulated devices, perform electrical impedance or leak tests as applicable.

2.5 Data Analysis & Correlation

- Plot key degradation metrics (e.g., tensile strength retention) versus time for both RTA and AA arms.

- Calculate acceleration factors (AF) based on actual RTA data to refine predictive models.

- Use statistical methods (e.g., regression analysis) to assess correlation strength.

Data Presentation

Table 1: Baseline Characterization (T₀) Test Suite

| Test Category | Specific Test | Standard/ASTM Method | Key Parameters Measured |

|---|---|---|---|

| Physical | Density | D792 | Mass/Volume |

| Thermal | Differential Scanning Calorimetry (DSC) | D3418 | Glass Transition Temp (Tg), Melting Temp (Tm) |

| Thermal | Thermogravimetric Analysis (TGA) | E1131 | Decomposition Onset Temperature |

| Mechanical | Tensile Test | D412 | Ultimate Tensile Strength, Elongation at Break, Modulus |

| Surface | Fourier Transform Infrared Spectroscopy (FTIR) | E1252 | Chemical Functional Groups |

| Morphological | Scanning Electron Microscopy (SEM) | E986 | Surface Topography |

Table 2: Exemplary Accelerated Aging Timepoints (Based on Arrhenius, Assumed Ea=0.7 eV)

| Real-Time Condition | Accelerated Condition | Acceleration Factor (AF) | Real-Time Duration | Equivalent Accelerated Duration |

|---|---|---|---|---|

| 37°C / 97% RH | 50°C / 97% RH | ~3.1x | 36 months | ~11.6 months |

| 37°C / 97% RH | 50°C / 97% RH | ~3.1x | 60 months | ~19.4 months |

| 37°C / 97% RH | 65°C / 97% RH | ~8.7x | 36 months | ~4.1 months |

| 37°C / PBS | 55°C / PBS | ~4.5x | 24 months | ~5.3 months |

Visualizations

Title: Parallel Aging Study Workflow

Title: Logic of Model Validation via Real-Time Control

The Scientist's Toolkit: Key Research Reagent Solutions

| Item Name / Category | Function / Relevance in Aging Studies |

|---|---|

| Simulated Physiological Buffers (e.g., PBS, SBF) | Provides ionic and pH environment mimicking body fluids to study hydrolytic degradation and ion ingress. |

| Controlled Humidity Chambers | Enables precise long-term storage at specific relative humidity (e.g., 97% RH) for studying moisture-driven effects without full immersion. |

| Chemically Inert Vials (Type I Borosilicate Glass) | Prevents leachables/interactions that could confound material degradation results during long-term immersion studies. |

| Reference Standard Materials (e.g., known stability polymers) | Served as positive/negative controls to confirm stability of the aging environment and test methods over time. |

| Strain/Stress Jigs for Aged Mechanical Testing | Allows for mechanical testing of samples that may have become brittle or adhered, ensuring valid data capture post-aging. |

| Stability-Indicating Analytical Methods (e.g., HPLC for leachables, GPC for molecular weight) | Critical for quantifying chemical degradation products and changes in polymer chain length, directly measuring aging impact. |

Within accelerated aging studies for implantable encapsulation materials, systematic monitoring of physicochemical and mechanical property degradation is critical for predicting in vivo performance and shelf life. This note details standardized protocols for four core analytical techniques, providing a framework for generating comparable, quantitative degradation data.

Application Notes & Protocols

Fourier-Transform Infrared Spectroscopy (FTIR)

Application: Tracks chemical degradation mechanisms (e.g., hydrolysis, oxidation, chain scission) by identifying changes in functional groups and bond chemistry. Key Metrics: Shift in peak position (cm⁻¹), change in peak area/intensity (for carbonyl index, hydroxyl index), appearance/disappearance of specific peaks.

Protocol: FTIR Analysis of Degraded Polymer Films

Objective: To quantify oxidative or hydrolytic degradation in poly(lactic-co-glycolic acid) (PLGA) encapsulation films. Materials: Degraded polymer film samples, FTIR spectrometer with ATR accessory, force gauge, anhydrous ethanol, lint-free wipes. Procedure:

- Condition samples and spectrometer in a controlled atmosphere (e.g., 23°C, 50% RH) for 1 hour.

- Clean the ATR crystal thoroughly with ethanol and background scan.

- Place film on crystal, apply uniform pressure via instrument's torque arm.

- Acquire spectrum in range 4000-600 cm⁻¹, 32 scans, 4 cm⁻¹ resolution.

- Process spectra: baseline correct, normalize to a stable reference peak (e.g., C-H stretch at ~2950 cm⁻¹).

- Calculate degradation indices (e.g., Carbonyl Index = Area of C=O peak ~1750 cm⁻¹ / Area of reference peak).

Table 1: Representative FTIR Degradation Indices for PLGA (85:15) Under Accelerated Aging

| Aging Condition (70°C, 75% RH) | Carbonyl Index (Initial) | Carbonyl Index (8 Weeks) | Hydroxyl Index (Initial) | Hydroxyl Index (8 Weeks) |

|---|---|---|---|---|

| Control (0 Weeks) | 1.00 ± 0.05 | - | 0.15 ± 0.02 | - |

| Sample Batch A | - | 1.45 ± 0.08 | - | 0.41 ± 0.05 |

| Sample Batch B | - | 1.82 ± 0.10 | - | 0.58 ± 0.07 |

Differential Scanning Calorimetry (DSC)

Application: Monitors changes in thermal transitions (glass transition Tg, melting Tm, crystallization Tc, enthalpy) indicating chain mobility, crystallinity, and molecular weight changes.

Protocol: DSC for Thermal Transition Analysis

Objective: To determine the glass transition temperature (Tg) and degree of crystallinity in aged polyurethane encapsulation materials. Materials: DSC instrument, sealed aluminum Tzero pans/lids, microbalance, cooled chilling unit. Procedure:

- Precisely weigh 5-10 mg of sample into a pan and hermetically seal.

- Load sample and inert reference pan.

- Run heat/cool/heat cycle under N₂ purge (50 mL/min): Equilibrate at -80°C, heat to 250°C at 10°C/min (1st heat), cool to -80°C at 10°C/min, re-heat to 250°C at 10°C/min (2nd heat).

- Analyze the 2nd heating curve for Tg (midpoint), Tm (peak), and enthalpies (ΔHm).

- Calculate percent crystallinity: Xc(%) = [ΔHm / ΔHm°] * 100, where ΔHm° is enthalpy for 100% crystalline polymer.

Table 2: DSC Data for Polyurethane After In Vitro Hydrolytic Aging

| Aging Time (Weeks, 90°C PBS) | Tg (°C) | Tm (°C) | ΔHm (J/g) | Calculated Xc (%) |

|---|---|---|---|---|

| 0 (Control) | -25.2 ± 0.5 | 155.3 ± 1.2 | 12.5 ± 0.8 | 8.9 ± 0.6 |

| 2 | -22.1 ± 0.7 | 154.8 ± 1.5 | 15.1 ± 1.0 | 10.8 ± 0.7 |

| 4 | -18.5 ± 0.9 | 153.9 ± 1.8 | 18.7 ± 1.2 | 13.4 ± 0.9 |

| 8 | -15.0 ± 1.2 | 152.0 ± 2.1 | 20.5 ± 1.5 | 14.6 ± 1.1 |

Tensile Testing

Application: Quantifies the loss of mechanical integrity via ultimate tensile strength (UTS), elongation at break (EAB), and modulus.

Protocol: Uniaxial Tensile Test for Thin Films

Objective: To assess the embrittlement of silicone elastomer encapsulation sheets after thermal oxidative aging. Materials: Universal tensile tester, film micro-dogbone cutter (ASTM D1708), non-contact extensometer, calipers. Procedure:

- Die-cut 5+ dogbone specimens per sample group (gage dimensions: ~22 mm x 3.2 mm x 0.5 mm thick).

- Measure thickness at three points in gage section with digital micrometer.

- Mount specimen with pneumatic grips at a gauge length of 22 mm. Ensure alignment.

- Apply pre-tension of 0.01 N. Attach extensometer if required.

- Extend specimen at constant crosshead speed of 50 mm/min until fracture.

- Record stress-strain curve. Calculate UTS (MPa), EAB (%), and Young's Modulus (MPa) from linear elastic region.

Table 3: Tensile Properties of Medical-Grade Silicone After Thermal Aging

| Aging Condition (150°C, Air) | UTS (MPa) | Elongation at Break (%) | Young's Modulus (MPa) |

|---|---|---|---|

| 0 Days (Control) | 10.2 ± 0.8 | 850 ± 50 | 1.21 ± 0.15 |

| 3 Days | 9.5 ± 0.7 | 720 ± 45 | 1.35 ± 0.18 |

| 7 Days | 8.1 ± 0.9 | 550 ± 60 | 1.65 ± 0.20 |

| 14 Days | 6.3 ± 1.1 | 300 ± 70 | 2.10 ± 0.25 |

Permeability Testing

Application: Measures the change in barrier properties critical for protecting implanted electronics or drugs (e.g., water vapor transmission rate - WVTR).

Protocol: Coulometric Sensor Method for WVTR

Objective: To determine the increase in water vapor transmission rate of parylene C coatings on substrates. Materials: Coulometric sensor-based permeability tester (e.g., MOCON), test cells, dry nitrogen carrier gas, film specimens. Procedure:

- Cut film to cover test cell aperture (e.g., 50 cm²). Ensure no wrinkles or damage.

- Seal film in test cell using provided gasket. Apply uniform torque.

- Place cell in instrument. One side is exposed to a controlled humidified gas stream (e.g., 90% RH, 37°C), the other to dry N₂ carrier.

- Water vapor permeating is carried to a coulometric sensor. Measure until steady-state flux is achieved (≥ 3 consecutive stable readings).

- Calculate WVTR in g/(m²·day). Repeat for n≥3 samples.

Table 4: WVTR of Parylene C Films After Accelerated Aging (60°C/95% RH)

| Aging Duration (Months) | WVTR at 37°C, 90% RH (g/(m²·day)) | Permeability Increase Factor |

|---|---|---|

| 0 | 0.85 ± 0.10 | 1.0 |

| 3 | 1.12 ± 0.15 | 1.3 |

| 6 | 1.75 ± 0.20 | 2.1 |

| 9 | 2.90 ± 0.30 | 3.4 |

Visualizations

Diagram Title: Multi-Technique Degradation Tracking Workflow

Diagram Title: Degradation Modes and Corresponding Analytical Techniques

The Scientist's Toolkit: Key Research Reagent Solutions

Table 5: Essential Materials for Encapsulation Material Degradation Studies

| Item/Reagent | Function/Application in Protocols |

|---|---|

| Phosphate-Buffered Saline (PBS), pH 7.4 | Standard hydrolytic aging medium for simulating physiological conditions. |

| Anhydrous Ethanol (ACS Grade) | For cleaning ATR crystals and sample surfaces prior to FTIR/DSC. |

| Hermetic Tzero DSC Pans & Lids | Ensure no mass loss or contamination during DSC thermal cycles. |

| Standard Film Thickness Gauge (Digital Micrometer) | Critical for accurate cross-sectional area calculation in tensile testing. |

| Coulometric Desiccant (for Permeability Testers) | Regenerative desiccant in sensors for precise water vapor measurement. |

| ASTM-Calibrated Tensile Test Dumbbell Die | Ensures consistent, comparable specimen geometry per ASTM/ISO standards. |

| Inert Sealing Grease (e.g., high-vacuum silicone) | For creating reliable seals in custom permeability or aging fixtures. |

| Certified Reference Materials (e.g., Indium for DSC, PET films for WVTR) | For instrument calibration and validation of all quantitative methods. |

This application note provides a structured test plan for a novel bioresorbable encapsulation polymer, framed within a doctoral thesis on accelerated aging methodologies for implantable encapsulation materials. The primary objective is to establish a predictive framework correlating accelerated in vitro degradation with long-term in vivo performance, enabling efficient screening and qualification of next-generation encapsulation systems for drug delivery and medical devices.

Accelerated Degradation Testing Protocol

Objective

To simulate and predict the hydrolytic degradation profile of the novel polymer under accelerated conditions, establishing degradation rate constants and identifying potential failure modes.

Detailed Methodology

Materials:

- Polymer films or devices (e.g., 10 mm x 10 mm x 0.5 mm).

- Phosphate Buffered Saline (PBS), pH 7.4 ± 0.1.

- Sodium azide (0.02% w/v) as antimicrobial agent.

- Controlled temperature water baths or environmental chambers (37°C, 50°C, 70°C).

- Analytical balance (±0.01 mg).

- Gel Permeation Chromatography (GPC) system.

- Differential Scanning Calorimetry (DSC).

- Tensile tester.

Procedure:

- Sample Preparation: Pre-weigh (M₀) and measure initial dimensions of sterile polymer samples (n=6 per group).

- Immersion: Immerse samples in PBS containing sodium azide. Use a volume-to-surface area ratio ≥ 20 mL/cm².

- Incubation: Incubate samples at three temperatures: physiological (37°C) and accelerated (50°C, 70°C). Use hermetic sealing to prevent evaporation.

- Time Points: Remove samples at predetermined intervals (e.g., 1, 2, 4, 8, 12, 16, 20, 24 weeks).

- Analysis:

- Mass Loss: Rinse samples, dry to constant mass (Mₜ), calculate mass loss: ((M₀ - Mₜ)/M₀) * 100%.

- Molecular Weight: Analyze via GPC to track number-average molecular weight (Mₙ) decrease.

- Thermal Properties: Analyze via DSC for changes in glass transition (Tg) and crystallinity.

- Mechanical Properties: Perform tensile testing to monitor modulus, strength, and elongation-at-break.

- Data Modeling: Apply the Arrhenius equation to model the temperature dependence of degradation rate constants (e.g., for mass loss or Mₙ reduction) and predict shelf-life or functional life at 37°C.

Data Presentation: Degradation Kinetics

Table 1: Summary of Accelerated Hydrolytic Degradation Data for Polymer X

| Time Point (Weeks) | Condition (Temp.) | Avg. Mass Loss (%) | Avg. Mₙ Reduction (%) | Tensile Strength Retention (%) |

|---|---|---|---|---|

| 4 | 37°C | 1.2 ± 0.3 | 15 ± 2 | 98 ± 2 |

| 4 | 50°C | 5.8 ± 0.7 | 42 ± 4 | 85 ± 5 |

| 4 | 70°C | 22.5 ± 2.1 | 78 ± 6 | 45 ± 8 |

| 12 | 37°C | 4.5 ± 0.5 | 38 ± 3 | 90 ± 4 |

| 12 | 50°C | 18.3 ± 1.5 | 81 ± 5 | 30 ± 7 |

| 12 | 70°C | 95.0* ± 3.0 | 98* ± 1 | 5* ± 2 |

Note: Data based on simulated projections for a fast-degrading poly(lactide-co-glycolide) variant. *Indicates complete degradation/loss of integrity.

Biocompatibility and Bioresponse Assessment Protocol

Objective

To evaluate the in vitro cytotoxicity and inflammatory potential of polymer degradation products.

Detailed Methodology (ISO 10993-5 & -12)

Materials:

- Mouse fibroblast cell line (L929) or human primary macrophages.

- Complete cell culture medium.

- Extraction vehicle: Serum-free medium or PBS.

- MTT or PrestoBlue cell viability assay kit.

- ELISA kits for inflammatory cytokines (TNF-α, IL-1β, IL-6).

Procedure:

- Extract Preparation: Inc polymer samples in extraction vehicle at 37°C for 72h at a surface area-to-volume ratio of 3 cm²/mL. Use a 0.1% zinc diethyldithiocarbamate solution as a cytotoxic positive control.

- Cytotoxicity (MTT Assay):

- Seed L929 cells in a 96-well plate.

- After 24h, replace medium with sample extracts (100% concentration) or dilutions.

- Incubate for 24h. Add MTT reagent. Incubate for 4h.

- Solubilize formazan crystals with DMSO.

- Measure absorbance at 570 nm. Calculate viability relative to negative control.

- Macrophage Activation Assay:

- Seed THP-1 derived macrophages.

- Treat with degradation-conditioned medium (from Protocol 2.2).

- After 48h, collect supernatant.

- Quantify cytokine release via ELISA.

Data Presentation: Biocompatibility

Table 2: In Vitro Biocompatibility Assessment of Polymer X Degradation Products

| Assay Type | Test Article | Result (vs. Control) | Conclusion |

|---|---|---|---|

| Cytotoxicity | 24h Extract (100% conc.) | Cell Viability: 92% ± 5% | Non-cytotoxic (≥70% viability) |

| Cytotoxicity | 72h Extract (100% conc.) | Cell Viability: 85% ± 7% | Non-cytotoxic |

| Inflammation | Medium from 12wk/50°C Degradation | IL-6: 2.1x increase* | Mild inflammatory response detected |

| Inflammation | Medium from 4wk/37°C Degradation | IL-6: 1.2x increase* | Negligible response |

Note: *Fold-change vs. fresh medium control.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Bioresorbable Polymer Testing

| Item (Supplier Example) | Function / Role in Experiments |

|---|---|

| Phosphate Buffered Saline (PBS), pH 7.4 (Thermo Fisher) | Primary immersion medium for hydrolytic degradation studies, simulating physiological ionic strength. |

| Sodium Azide (Sigma-Aldrich) | Antimicrobial agent added to degradation media to prevent microbial growth confounding results. |

| GPC/SEC Standards (e.g., Agilent, Waters) | Calibrants for Gel Permeation Chromatography to accurately determine polymer molecular weight. |

| DSC Crucibles (Aluminum, Tzero) (TA Instruments) | Hermetic pans for Differential Scanning Calorimetry to analyze thermal transitions without artefact. |

| MTT Cell Viability Assay Kit (Abcam) | Colorimetric assay to quantify metabolic activity and cytotoxicity of polymer extracts. |

| Human Cytokine ELISA Panel (R&D Systems) | Multiplexed quantification of inflammatory markers (TNF-α, IL-1β) released by immune cells. |

| Poly(lactide-co-glycolide) Controls (Evonik, Corbion) | Well-characterized reference materials for benchmarking degradation and performance. |

| Simulated Body Fluid (SBF) (Modified Kokubo Recipe) | Solution with ion concentrations similar to blood plasma, used for biomineralization studies. |

Visualized Workflows and Pathways

Diagram Title: Accelerated Aging & Biocompatibility Test Workflow

Diagram Title: Polymer Degradation Cascade & Bioresponse

Navigating Pitfalls: Common Challenges, Material-Specific Failures, and Strategies for Optimizing Test Validity

Application Notes

Accelerated aging testing, based on the Arrhenius equation, is the cornerstone of predicting the long-term stability and service life of implantable encapsulation materials (e.g., silicones, polyurethanes, parylene). The fundamental assumption is that temperature-dependent degradation modes (e.g., hydrolysis, oxidation) have a constant activation energy (Ea). Non-Arrhenius behavior occurs when this assumption fails, leading to inaccurate—and potentially unsafe—lifetime predictions. For encapsulation protecting active implantable medical devices or drug-eluting implants, such inaccuracies can result in catastrophic failure in vivo.

Key Indicators of Non-Arrhenius Behavior:

- Multi-Mechanism Degradation: At different temperature regimes, distinct physical or chemical processes dominate. For example, chain scission may dominate at high test temperatures, while plasticizer leaching or swelling-driven stress cracking governs lower, use-condition temperatures.

- Phase Transitions: The material undergoes a glass transition (Tg), crystallization, or melting within the accelerated test range, drastically altering diffusion kinetics and reaction rates.

- Diffusion-Limited Reactions: When the rate-controlling step shifts from chemical reaction kinetics at high temperature to water/oxygen diffusion at lower temperature.

- Environmental Stress Cracking: Synergistic effects of chemical agents (body fluids) and stress, which are not accurately accelerated by temperature alone.

- Relaxation of Internal Stresses: Processing-induced stresses relax during high-temperature aging, causing morphological changes not representative of real-time aging.

Consequences for Implant Research: Ignoring non-Arrhenius behavior can lead to both overly optimistic predictions (if a low-Ea process kicks in at body temperature) or overly pessimistic predictions (if a high-Ea process becomes irrelevant at use conditions). This directly impacts regulatory submissions (e.g., FDA, EMA), shelf-life assignment, and ultimately patient safety.

Experimental Protocols

Protocol 2.1: Multi-Temperature Regime Kinetic Analysis

Objective: To identify shifts in apparent activation energy (Ea) across a broad temperature range, indicating a change in the dominant degradation mechanism.

Materials: See Scientist's Toolkit. Method:

- Sample Preparation: Prepare identical test coupons (e.g., 1mm thick sheets) of the encapsulation material. Ensure consistent thermal history.

- Aging Chambers: Place samples in controlled environmental chambers at a minimum of four elevated temperatures (e.g., 55°C, 70°C, 85°C, 100°C) and a control (23°C). Humidity should be controlled to a relevant level (e.g., 95% RH for hydrolytic stability).

- Time Points: Remove replicates at predetermined intervals (e.g., 1, 2, 4, 8, 12, 16 weeks).

- Critical Property Measurement: At each interval, measure a property relevant to implant function:

- Tensile Strength & Elongation at Break: (ASTM D412)

- Water Vapor Transmission Rate (WVTR): (ASTM E96)

- Molecular Weight: Via Gel Permeation Chromatography (GPC).

- Surface Chemistry: Via ATR-FTIR.

- Data Modeling: For each temperature, plot the log of the property degradation rate (e.g., % tensile strength loss per week) against the inverse of absolute temperature (1/T). Perform linear regression for sequential temperature pairs.

Analysis: A single, straight line across all temperatures confirms Arrhenius behavior. A distinct break or curve in the Arrhenius plot indicates non-Arrhenius behavior, signifying a shift in Ea.

Title: Workflow for Identifying Non-Arrhenius Kinetics

Protocol 2.2: Failure Mode Comparison via Accelerated vs. Real-Time Aged Samples

Objective: To correlate failure modes observed at high-temperature acceleration with those occurring under real-time, use-condition aging.

Method:

- Parallel Aging: Age material samples in two regimes:

- Accelerated: 85°C / 85% RH for 6 months.

- Real-Time: 37°C in simulated physiological fluid (e.g., PBS, pH 7.4) for 2-3 years.

- Post-Aging Analysis: Subject aged samples from both regimes to identical, detailed analytical suites:

- Microscopy: SEM for surface cracking, delamination, pitting.

- Thermal Analysis: DSC to detect changes in Tg, crystallinity, or enthalpic relaxations.

- Chemical Analysis: FTIR and XPS to compare oxidation profiles or hydrolysis products.

- Mechanical Test: As in Protocol 2.1.

- Correlation Matrix: Create a table comparing the type, severity, and morphology of degradation features between the two regimes.

Analysis: A strong correlation supports the validity of the accelerated model. Divergent failure modes (e.g., bulk embrittlement at high temp vs. surface-localized cracking at 37°C) are definitive evidence of non-Arrhenius behavior and invalidate simple extrapolation.

Data Presentation

Table 1: Example Kinetic Data Showing Non-Arrhenius Behavior in Polyurethane Encapsulant

| Aging Temperature (°C) | Degradation Rate, k (%/week) - Tensile Loss | Apparent Activation Energy, Ea (kJ/mol) Calculated from adjacent T | Dominant Degradation Mode Identified |

|---|---|---|---|

| 100 | 1.25 | -- | Radical oxidation (chain scission) |

| 85 | 0.45 | 95 | Radical oxidation (chain scission) |

| 70 | 0.18 | 90 | Hydrolysis (ester group) |

| 55 | 0.09 | 55 | Hydrolysis (ester group) |

| 37 (Use) | 0.02 (extrapolated) | -- | INVALID EXTRAPOLATION |

| 37 (actual, 2 yr) | 0.01 (measured) | -- | Stress corrosion cracking |

Interpretation: The drop in apparent Ea between 85°C and 70°C indicates a shift from oxidation-dominated to hydrolysis-dominated degradation. Simple extrapolation from the high-T data (Ea=95 kJ/mol) predicts a rate of 0.02%/week at 37°C. The actual measured rate is half that, governed by a different (diffusion/Stress) mechanism, confirming non-Arrhenius behavior.

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function in Non-Arrhenius Studies |

|---|---|