Strategies for Enhancing Chronic Signal Fidelity in Next-Generation Neural Interfaces

This article provides a comprehensive analysis of the latest strategies to overcome the critical challenge of signal degradation in chronically implanted neural interfaces.

Strategies for Enhancing Chronic Signal Fidelity in Next-Generation Neural Interfaces

Abstract

This article provides a comprehensive analysis of the latest strategies to overcome the critical challenge of signal degradation in chronically implanted neural interfaces. Tailored for researchers, scientists, and drug development professionals, it explores the root causes of chronic failure, including foreign body response and mechanical mismatch. The scope spans foundational material science innovations in flexible bioelectronics, advanced methodological approaches in high-density electrode fabrication and multimodal integration, and optimized surgical and drug-delivery strategies. Furthermore, it examines validation through clinical trials and comparative performance of emerging technologies, offering a roadmap for developing stable, high-fidelity neural interfaces for long-term research and therapeutic applications.

Understanding the Chronic Stability Challenge: Biocompatibility and Foreign Body Response

Frequently Asked Questions (FAQs)

FAQ 1: What are the primary biological events leading to glial scar formation after neural device implantation? The formation of a glial scar is a sequential process initiated by the implantation injury [1]. The breach of the blood-brain barrier allows blood-serum proteins to enter the brain tissue, triggering an immediate activation of microglia [1]. These resident immune cells adopt an amoeboid shape, proliferate, and migrate to the implant site, releasing proinflammatory cytokines [1]. Subsequently, astrocytes become activated, proliferate, hypertrophy, and over a period of 4 to 6 weeks, encapsulate the device in a dense scar tissue [1]. This scar, composed of reactive glia and deposited extracellular matrix proteins like chondroitin sulphate proteoglycan (CSPG), acts as an insulating barrier [2].

FAQ 2: How does the glial scar directly impact the recording quality and longevity of neural interfaces? The glial scar impacts signal fidelity through two primary mechanisms: increased electrode impedance and neuronal loss. The dense, insulating nature of the glial scar increases the electrical impedance at the electrode-tissue interface, which attenuates the amplitude of recorded neural signals [3]. Concurrently, the chronic inflammatory environment and the physical barrier created by the scar lead to the death or migration of neurons away from the electrode site [4] [3]. This increases the distance between viable neurons and the recording sites, resulting in a rapid degradation of signal quality and signal loss over time [3].

FAQ 3: Why are flexible electrodes considered superior to rigid ones for chronic implants? Flexible electrodes, typically made from polymers like polyimide, have a lower Young's modulus that more closely matches that of soft brain tissue (approximately 1–10 kPa) [5] [6]. This mechanical compatibility minimizes the chronic micro-motions and persistent injury caused by mechanically rigid implants, which are a key driver of the foreign body response [5] [3]. Studies have shown that flexible probes can lead to a situation where reactive astrocyte transformation gradually returns to a baseline homeostatic state over long implantation periods (e.g., 18 weeks), a phenomenon not typically observed with rigid probes [4].

FAQ 4: Can we completely prevent glial scarring, and should we? Complete prevention of glial scarring is likely neither feasible nor desirable in the acute phase. The initial glial response acts as a protective mechanism that seals the lesion and prevents the spread of damage to healthy surrounding tissue [2]. The research focus has therefore shifted from complete prevention to modulation and control of the reaction. The goal is to mitigate the chronic, persistent aspects of the scar that are detrimental to signal fidelity while allowing the initial, beneficial healing processes to occur [4] [2]. Strategies aim to reduce scar density and thickness to levels that do not significantly impede electrical or biochemical communication.

Troubleshooting Guides

Table 1: Common Experimental Challenges and Solutions

| Challenge & Symptom | Underlying Cause | Verified Solution | Key References |

|---|---|---|---|

| Rapid signal attenuation within weeks of implantation. | Chronic inflammation and dense glial scarring increasing impedance and displacing neurons. | Utilize flexible electrodes with smaller cross-sections (< 100 μm²) to minimize mechanical mismatch and vascular damage. | [5] [3] [7] |

| High variability in signal quality across electrodes in an array. | Inconsistent tissue integration and variable glial encapsulation around different shanks. | Implement surface coatings like the TAB coating (BDNF + lubricant) to promote uniform neural and astrocytic integration while repelling immune cells. | [8] |

| Acute inflammation and bleeding during implantation surgery. | Large probe footprint and rigid insertion method causing significant vascular damage. | Use biodegradable polymer needles (e.g., PLGA) as insertion shuttles for flexible wires, which dissolve post-implantation. | [7] |

| Failure to record stable single-unit activity over months. | Neuronal loss and unstable electrode-tissue interface due to micromotions. | Design probes with cross-sectional areas at a subcellular level (e.g., 10 μm² nanowires) to mimic neural structures and reduce footprint. | [5] |

Table 2: Quantitative Data on Scarring and Performance

| Experimental Variable | Impact on Glial Scar Thickness | Impact on Recordable Neuron Count | Longevity of High-Quality Recording | Key References |

|---|---|---|---|---|

| Rigid Silicon Probes | Significant (>100 μm) | Large decrease | Several months | [3] [6] |

| Flexible Polyimide Probes | Reduced | Moderate decrease | >8 months | [4] [5] |

| Ultra-Small Carbon Fibers (7 μm diameter) | Minimal | Minimal change | >7 weeks | [5] [3] |

| TAB-coated Flexible Fibers | Not Reported | Increased adhesion | >12 months | [8] |

| Thin Microwires (8x10 μm cross-section) | Low (~80 μm at 2 months) | Not Reported | Not Reported | [7] |

Experimental Protocols

Protocol 1: Histological Assessment of Glial Scarring

This protocol details the methodology for quantifying glial scar formation around an implanted neural probe, a key metric for evaluating biocompatibility [7].

- Primary Antibodies: Mouse anti-GFAP (for reactive astrocytes) and Rabbit anti-Iba1 (for activated microglia).

- Secondary Antibodies: Alexa Fluor 488-conjugated goat anti-mouse and Alexa Fluor 594-conjugated goat anti-rabbit.

- Other Reagents: Phosphate Buffered Saline (PBS), 4% Paraformaldehyde (PFA), Triton X-100, blocking serum (e.g., normal goat serum), and mounting medium with DAPI.

Step-by-Step Workflow:

- Perfusion and Fixation: At the designated endpoint, transcardially perfuse the animal with ice-cold PBS followed by 4% PFA. Extract the brain and post-fix it in 4% PFA for 24 hours.

- Cryosectioning: Cryoprotect the fixed brain in a 30% sucrose solution. Embed the tissue in OCT compound and section it coronally into 40 μm thick slices using a cryostat.

- Immunostaining:

- Blocking: Incubate free-floating sections in a blocking solution (e.g., 5% normal goat serum in PBS with 0.3% Triton X-100) for 2 hours at room temperature.

- Primary Incubation: Incubate sections with primary antibodies (anti-GFAP and anti-Iba1) diluted in blocking solution for 48 hours at 4°C.

- Washing: Wash sections 3 times for 15 minutes each with PBS.

- Secondary Incubation: Incubate sections with species-appropriate fluorescent secondary antibodies for 2 hours at room temperature, protected from light.

- Counterstaining and Mounting: Wash again, counterstain with DAPI to label nuclei, and mount the sections on glass slides.

- Imaging and Analysis: Image the tissue using a confocal or epifluorescence microscope. Quantify glial scar thickness by measuring the intensity of GFAP and Iba1 staining as a function of distance from the implant track. The scar thickness is typically defined as the distance where the fluorescence intensity returns to baseline levels.

Protocol 2: Functional Evaluation via Chronic Electrophysiology

This protocol describes how to track the stability of neural recording performance over time, which is the functional correlate of tissue integration.

- Equipment: Implantable neural probe (e.g., flexible MEA), headstage, data acquisition system, and spike-sorting software.

- Key Metrics: Signal-to-noise ratio (SNR), single-unit yield, and amplitude of detected action potentials.

Step-by-Step Workflow:

- Surgical Implantation: Sterilize the probe. Implant the device into the target brain region using an appropriate surgical technique and sterile shuttle if needed. Secure the device to the skull with dental cement.

- Data Acquisition: Connect the headstage to the implanted device at regular intervals (e.g., daily for the first week, then weekly). Record spontaneous neural activity or activity evoked by a controlled stimulus.

- Signal Processing:

- Spike Sorting: Filter the raw data (e.g., 300 Hz to 6 kHz bandpass filter) to isolate action potentials. Use spike sorting algorithms (e.g., Kilosort, MountainSort) to cluster spikes and assign them to individual neurons based on waveform features.

- Metric Calculation:

- Single-Unit Yield: Calculate the number of well-isolated single units per active electrode.

- Signal Amplitude: Track the peak-to-valley amplitude of the average waveform for each identified unit over time.

- Signal-to-Noise Ratio (SNR): Calculate as the ratio of the peak-to-peak spike amplitude to the RMS of the background noise.

- Longitudinal Analysis: Plot the calculated metrics (yield, amplitude, SNR) as a function of time post-implantation. A stable or gradually increasing profile indicates good functional integration, while a sharp decline suggests a strong foreign body response.

Key Signaling Pathways in Glial Scarring

The formation of a glial scar is orchestrated by a complex cascade of cellular signaling events [4] [1] [2].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Neural Interface Biocompatibility Research

| Item | Function & Utility | Example Application |

|---|---|---|

| Flexible Polymer Substrates (Polyimide, Parylene) | Serves as the base material for neural probes; provides mechanical compliance with brain tissue to reduce chronic inflammation. | Fabrication of low-modulus microelectrodes for chronic implantation [4] [5]. |

| Biodegradable PLGA Needles | Acts as a rigid shuttle for implanting flexible microwires; degrades post-surgery, eliminating a source of chronic mechanical mismatch [7]. | Guided implantation of ultra-thin flexible electrodes without leaving a permanent rigid component [7]. |

| TAB Coating (PFS + Aminosilane + BDNF) | A multifunctional surface modification. The Perfluorosilane (PFS) layer holds a lubricant for antifouling, while immobilized BDNF promotes selective neuron/astrocyte adhesion [8]. | Coating for flexible fibers to achieve long-term (>12 months) single-unit recordings by enhancing neural integration [8]. |

| Anti-GFAP & Anti-Iba1 Antibodies | Gold-standard markers for identifying reactive astrocytes and activated microglia, respectively, in immunohistochemistry. | Histological quantification of glial scar thickness and cellular composition around implants [7]. |

| Neuropixels Probes | High-density silicon-based neural probes for large-scale electrophysiology; allow tracking of hundreds to thousands of neurons simultaneously. | Functional evaluation of neuronal density and activity stability around the implant site over time [9]. |

| Orientin-2''-O-p-trans-coumarate | Orientin-2''-O-p-trans-coumarate, CAS:73815-15-3, MF:C30H26O13, MW:594.525 | Chemical Reagent |

| 1,3-Dimyristoyl-2-oleoylglycerol | Glycerol 1,3-ditetradecanoate 2-(9Z-octadecenoate) |

A fundamental challenge in developing reliable chronic neural interfaces is the significant mechanical mismatch that exists between conventional implantable electrodes and the soft neural tissues they are designed to interface with. This discrepancy in mechanical properties is a primary source of failure, limiting the long-term stability and signal fidelity of these devices. The brain is a soft, dynamic environment with a Young's modulus in the range of 1–10 kPa, whereas traditional electrode materials, such as silicon (~180 GPa) and platinum (~100 GPa), are many orders of magnitude stiffer [10] [11]. This mismatch prevents seamless integration, leading to tissue damage during insertion, chronic inflammation from persistent micromotion, and the eventual formation of an insulating glial scar that degrades signal quality [10] [12]. This technical support document outlines the failure mechanisms arising from this dilemma and provides evidence-based troubleshooting strategies for researchers aiming to improve chronic neural recordings.

Troubleshooting Guides

Guide: Diagnosing and Mitigating Chronic Signal Degradation

Problem: A chronically implanted neural electrode shows a progressive decline in recorded signal-to-noise ratio and an increase in electrode impedance over several weeks.

Background: This is a classic symptom of the foreign body response (FBR), which is often exacerbated by mechanical mismatch. The rigid electrode continuously irritates the surrounding tissue due to brain micromotion (e.g., from breathing and pulsation, causing 1–25 µm displacements) [13]. This leads to a cascade of cellular events: activated microglia release inflammatory factors, astrocytes proliferate and migrate to the injury site, and a dense glial scar forms, effectively insulating the electrode from nearby neurons [10] [12].

Investigation and Solution Protocol:

Step 1: Verify the Failure Mode

- Action: Perform electrochemical impedance spectroscopy (EIS) and post-explantation scanning electron microscopy (SEM) on the device.

- Expected Findings: EIS will show a steady increase in impedance at the electrode-tissue interface. SEM may reveal material failure, such as cracked insulation or delamination of conductive traces, often concentrated near recording sites where mechanical strain is highest [14] [12].

Step 2: Evaluate the Biological Response

- Action: For animal studies, perform histological analysis of the implant site post-explantation.

- Expected Findings: Immunostaining for markers like GFAP (astrocytes) and Iba1 (microglia) will likely reveal a dense glial sheath around the probe tract, with neurons pushed away from the electrode surface [12].

Step 3: Implement a Corrective Strategy

- Primary Solution: Transition to a soft, flexible electrode substrate.

- Protocol:

- Material Selection: Fabricate devices using soft polymers such as polyimide (PI), polydimethylsiloxane (PDMS), or SU-8 [10] [15]. These materials have a lower Young's modulus, which better matches that of brain tissue.

- Device Design: Utilize ultra-thin (<10 µm) or mesh-like geometric designs to drastically reduce the device's bending stiffness, allowing it to conform to the brain and move with it, thus minimizing micromotion-induced damage [10] [5].

- Implantation Technique: Employ a rigid shuttle (e.g., tungsten wire or SU-8 needle) coated with a biodegradable adhesive like polyethylene glycol (PEG) to temporarily stiffen the flexible probe for reliable insertion. The shuttle is retracted after implantation, leaving the flexible device in place [5].

Guide: Addressing Acute Insertion Damage and Vascular Injury

Problem: Upon implantation, the electrode causes significant bleeding or records poor initial signals, suggesting substantial acute tissue trauma.

Background: The rigidity and large cross-sectional area of a probe can cause tearing of neural tissue and rupture of blood vessels during insertion. This breaches the blood-brain barrier (BBB), leading to the release of blood cells, clotting factors, and neurotoxic plasma proteins, which initiates a severe inflammatory response and can cause secondary metabolic injury [14] [12].

Investigation and Solution Protocol:

Step 1: Assess Probe Geometry and Sharpness

Step 2: Implement a Corrective Strategy

- Primary Solution: Optimize the probe's geometry and implantation strategy to minimize the insertion footprint.

- Protocol:

- Miniaturization: Design probes with a smaller cross-section. "Filament-like" or "nanowire" electrodes with subcellular dimensions (e.g., < 10 µm in width) have been shown to significantly reduce acute injury [5].

- Distributed Implantation: Instead of a single, large multi-shank array, consider using multiple, smaller filaments implanted distributedly. This approach minimizes the cross-sectional area of a single implantation, promoting faster wound healing with minimal scarring [5].

- Robotic Assistance: Utilize robotic-assisted implantation technology for higher precision and reduced velocity during insertion, which can help avoid major blood vessels [5].

Frequently Asked Questions (FAQs)

FAQ 1: What are the primary mechanical and material failure modes of rigid silicon-based planar electrodes?

The most common failure modes are delamination, cracking, and corrosion, particularly at the interface between different materials. Finite Element Modeling (FEM) has demonstrated that mechanical strain concentrates at the borders of materials with clashing properties, such as iridium recording sites and the silicon substrate [14]. For example, the strain is further focused on small protrusions like electrical traces. Over time, chronic micromotion leads to cyclic stress at these points, causing insulation cracks, trace breakage, and eventual loss of electrical conductivity [14] [12].

FAQ 2: Besides flexibility, how can the surface of an electrode be modified to improve biocompatibility?

Surface functionalization is a key strategy to create "bioactive" interfaces. This involves coating the electrode with biomolecules that harness biochemical cues from the host tissue. Strategies include:

- Bioactive Coatings: Coatings with properties or components that mimic the extracellular matrix (ECM) can promote healthy integration.

- Drug-Eluting Coatings: Incorporating anti-inflammatory drugs (e.g., dexamethasone) into a biodegradable polymer coating allows for the local, controlled release of agents that actively suppress the inflammatory response [5] [12].

- Conductive Polymer Coatings: Using materials like PEDOT:PSS not only improves electrochemical performance by reducing impedance but can also be used as a matrix for incorporating bioactive molecules [10] [13].

FAQ 3: We are using flexible electrodes, but our chronic recordings are still unstable. What might we be overlooking?

The method of securing the device after implantation is critical and often overlooked. A common practice is to use rigid dental cement or a cover glass to secure the flexible electrode to the skull. This creates a "tethering" effect, where the rigid cover transfers outside-in pressure to the brain and prevents the flexible device from moving naturally with the brain's micromotion [13]. This can cause sustained local inflammation and tissue damage. The solution is to create a buffering interface. This can be achieved by using a soft artificial dura made of silicone, or by incorporating a soft, compressible layer (e.g., gelatin sponge or silicone elastomer) between the device and the cranial cover [13].

Table 1: Mechanical Properties of Neural Tissues and Common Electrode Materials

| Material / Tissue | Young's Modulus | Key Characteristics & Challenges |

|---|---|---|

| Brain Tissue | 1 - 30 kPa [10] | Soft, wet, dynamic; highly susceptible to mechanical damage. |

| PDMS | ~ 750 kPa - 2 MPa [13] [15] | Soft polymer; widely used for flexible substrates and encapsulation. |

| Polyimide (PI) | ~ 2.5 - 8.5 GPa [13] [15] | Flexible polymer film; common substrate for thin-film microfabrication. |

| Parylene-C | ~ 2.8 - 4 GPa [15] | Conformal coating; good barrier properties and flexibility. |

| Platinum (Pt) | ~ 168 GPa [15] | Noble metal; excellent conductivity and electrochemical stability. |

| Silicon (Si) | ~ 130 - 180 GPa [10] [14] | Rigid semiconductor; enables high-density, high-precision microfabrication. |

Table 2: Comparison of Electrode Implantation Strategies

| Implantation Strategy | Typical Cross-Section | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Unified (Single Shank) | 100 µm² and above [5] | Simpler surgery; stable for deep brain targets. | Larger acute injury; higher chronic FBR. |

| Distributed Filaments | < 100 µm² (subcellular) [5] | Minimal tissue displacement; promotes healing. | More complex implantation; requires robotic aid for scale. |

| Rigid Shuttle-Guided | Varies with shuttle size | Enables precise insertion of flexible probes. | Risk of shuttle detachment; potential for additional injury. |

Experimental Protocols

Protocol: Finite Element Modeling (FEM) for Strain Analysis in Planar Electrodes

Application: To identify regions of high mechanical stress and potential failure points in an electrode design before fabrication.

Background: FEM simulates how a physical structure responds to mechanical forces. It is used to model the von Mises Equivalent Elastic Strain, which represents the effective combined strain on an object [14].

Methodology:

- Model Creation: Develop a 3D model of the electrode (e.g., a 15 µm thick, 123 µm wide planar silicon shank) in engineering software (e.g., ANSYS).

- Material Properties: Assign accurate material properties (Young's modulus, Poisson's ratio) to each component (e.g., silicon substrate, iridium recording sites, insulation layers).

- Define Constraints and Loads: Fix the base of the electrode model. Apply a small displacement (e.g., 1 µm) to the tip of the electrode to simulate brain micromotion [14].

- Simulation and Analysis: Run the simulation to solve for strain distribution. Visually identify areas with the highest strain concentration, which are most vulnerable to cracking and delamination. Research has shown these are often at the borders of iridium recording sites and along protruding electrical traces [14].

Protocol: Implantation of a Flexible Electrode Using a Rigid, Biodegradable Shuttle

Application: To reliably implant a flexible neural probe that is too supple to penetrate brain tissue on its own.

Background: This method temporarily enhances the stiffness of a flexible probe for insertion, but leaves behind only the soft device, minimizing chronic mechanical mismatch [5].

Methodology:

- Shuttle Preparation: A rigid shuttle (e.g., a tungsten wire with a stepped tip) is passed through a guiding feature on the flexible electrode.

- Temporary Bonding: The assembly is fixed by coating it with a biodegradable adhesive, such as polyethylene glycol (PEG). This creates a stiff, unified structure.

- Stereotactic Implantation: The rigid shuttle is used to insert the flexible electrode to the target depth in the brain using standard stereotactic surgical procedures.

- Shuttle Retrieval: The PEG is dissolved using saline or bodily heat, decoupling the rigid shuttle from the flexible electrode. The shuttle is then carefully retracted, leaving the flexible electrode in place [5].

Signaling Pathways & Workflows

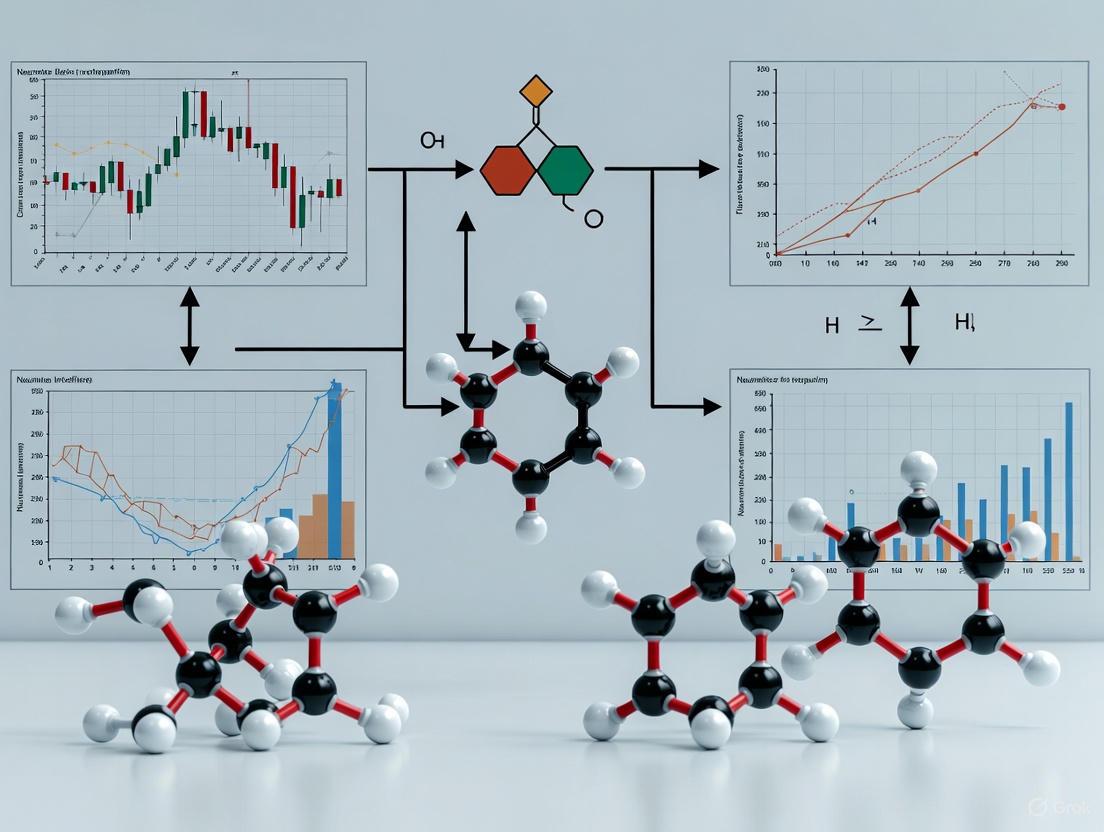

Diagram 1: The Pathway from Mechanical Mismatch to Signal Failure. This workflow illustrates the causal relationship between the initial mechanical mismatch and the ultimate failure of the neural interface, highlighting key biological responses.

The Scientist's Toolkit

Table 3: Essential Materials for Mitigating Mechanical Mismatch

| Research Reagent / Material | Primary Function in Addressing Mechanical Mismatch |

|---|---|

| Polyimide (PI) | A flexible polymer used as a substrate for thin-film electrodes, offering a much lower Young's modulus than silicon [5] [13]. |

| Polydimethylsiloxane (PDMS) | A soft elastomer used for substrates and encapsulation, providing excellent flexibility and biocompatibility [10] [15]. |

| PEDOT:PSS | A conductive polymer coating used to lower electrode impedance and improve signal transduction; can be functionalized with bioactive molecules [10] [13]. |

| Polyethylene Glycol (PEG) | A biodegradable polymer used as a temporary adhesive on rigid shuttles to enable the implantation of flexible electrodes [5]. |

| Iridium Oxide (IrOx) | A coating material for electrode sites with high charge injection capacity, crucial for safe and effective stimulation [15] [16]. |

| Ecoflex Silicone | An ultra-soft silicone used to create buffering interfaces and 3D structures that adapt to brain micromotion [13]. |

| Mal-NH-PEG4-CH2CH2COOPFP ester | Mal-NH-PEG4-CH2CH2COOPFP ester, CAS:1347750-84-8, MF:C24H27F5N2O9, MW:582.5 g/mol |

| N-(Boc-PEG5)-N-bis(PEG4-acid) | N-(Boc-PEG5)-N-bis(PEG4-acid), CAS:2093152-87-3, MF:C39H76N2O19, MW:877.0 g/mol |

Material Corrosion and Electrode Failure Over Time

Frequently Asked Questions (FAQs)

1. What are the primary causes of neural electrode failure over time? Electrode failure is typically caused by a combination of mechanical/material failure and biological tissue response. Material failure includes corrosion of the electrode metal, delamination of insulation, and cracking of conductive traces. The biological response involves inflammation, activation of immune cells (like microglia), and the formation of a glial scar that insulates the electrode from nearby neurons [12] [16].

2. Why does the impedance of my recording electrodes change after implantation? Impedance can increase due to several factors: the corrosion of electrode material (like tungsten), which can form insulating oxides; the delamination of insulation, creating current leaks; and the formation of a cellular capsule (glial scar) around the implant, which increases the physical distance between the electrode and viable neurons [12] [17].

3. How does the body's immune response affect chronic recording quality? The foreign body response leads to the activation of microglia and astrocytes, creating a dense glial scar around the implant. This scar insulates the electrode from nearby neurons and increases impedance. Furthermore, inflammatory cells release reactive oxygen species, such as hydrogen peroxide, which can accelerate the corrosion of electrode materials [12] [17].

4. Are some electrode materials more resistant to corrosion than others? Yes, materials vary significantly in their corrosion resistance. Platinum and platinum-iridium alloys are generally considered more inert and are commonly used in clinical electrodes. Tungsten, while strong and rigid, is susceptible to corrosion in physiological environments, especially in the presence of hydrogen peroxide produced during inflammation [16] [17].

Troubleshooting Guides

Problem: Gradual Deterioration of Neural Signal Quality

Potential Causes and Solutions

| Potential Cause | Diagnostic Method | Recommended Solution |

|---|---|---|

| Electrode Corrosion | Electrochemical Impedance Spectroscopy (EIS); Scanning Electron Microscopy (SEM) of explanted probes [12] [17]. | Switch to more corrosion-resistant materials (e.g., Pt/Ir); apply stable conductive coatings (e.g., Iridium Oxide) [16]. |

| Insulation Delamination | Optical and SEM inspection for cracks; monitoring for unexpected drops in impedance [12] [18]. | Improve polymer-metal adhesion (e.g., with oxygen plasma treatment); use more flexible, conformal insulation (e.g., Parylene, PDMS) [19] [18]. |

| Glial Scar Formation | Histological analysis (immunostaining for astrocytes and microglia) of surrounding tissue [12]. | Use flexible probes to reduce mechanical mismatch; apply bioactive anti-inflammatory coatings [12] [19]. |

Problem: Complete Loss of Signal from an Electrode Channel

Potential Causes and Solutions

| Potential Cause | Diagnostic Method | Recommended Solution |

|---|---|---|

| Complete Wire/Trace Fracture | Continuity testing; microscopic inspection for mechanical breaks [12] [16]. | Optimize device geometry to reduce strain concentration; use more durable, flexible conductive materials [12] [20]. |

| Severe Delamination or Encapsulation | Explant and analyze the device-tissue interface; impedance spectroscopy showing very high values [12] [18]. | Implement robust encapsulation strategies and hermetic sealing at connection points [16] [18]. |

The following table summarizes key quantitative findings from research on electrode performance and material corrosion.

| Parameter | Material/Electrode Type | Value/Outcome | Context & Implications |

|---|---|---|---|

| Chronic Recording Yield | Tungsten Microwires (Rat) | 24.6% at 260 days [12] | Highlights the challenge of maintaining single-unit recordings over long periods. |

| Total Failure Rate | Tungsten Microwires (Rat) | 75.4% at 260 days [12] | Indicates a high rate of complete signal loss with this model. |

| Tungsten Corrosion Rate | In vitro (PBS) | ~0.5 - 1.1 nm/day (est. from mass loss) [17] | Provides a baseline corrosion rate in a controlled saline environment. |

| Tungsten Corrosion Acceleration | In vitro (PBS + Hâ‚‚Oâ‚‚) | Rate increased significantly [17] | Demonstrates how the inflammatory environment can accelerate material failure. |

| Silicon Dioxide Dissolution | In aqueous environments | 3.7 - 43.5 pm/h [12] | A critical factor for the long-term stability of silicon-based probes. |

Experimental Protocols

Protocol 1: In Vitro Corrosion Assessment via Electrochemical Impedance Spectroscopy (EIS)

Objective: To evaluate the corrosion susceptibility and stability of electrode materials in a simulated physiological environment [17].

Materials:

- Working Electrode: The electrode material under test (e.g., tungsten, platinum wire).

- Reference Electrode: Standard Calomel Electrode (SCE) or Ag/AgCl electrode.

- Counter Electrode: Platinum mesh or wire.

- Electrolyte: Phosphate-Buffered Saline (PBS) or other simulated body fluid, optionally with added hydrogen peroxide (Hâ‚‚Oâ‚‚) to simulate inflammatory conditions [17].

- Potentiostat: A computer-controlled potentiostat capable of performing EIS.

Methodology:

- Setup: Place the working, reference, and counter electrodes in the electrolyte solution. Ensure a stable open-circuit potential (OCP) is reached before starting measurements.

- EIS Measurement: Apply a sinusoidal potential wave (e.g., 10 mV amplitude) over a range of frequencies (e.g., from 10 kHz to 10 mHz) at the OCP.

- Data Analysis:

- Plot the data in a Nyquist plot (imaginary impedance vs. real impedance).

- Fit the data to an appropriate equivalent circuit model. A model commonly used for corroding systems includes the solution resistance (Rs), a constant phase element (CPE), and the polarization resistance (Rp).

- The polarization resistance (Rp) is inversely proportional to the corrosion rate. A decreasing Rp over time indicates an increasing corrosion rate [17].

- Post-Experiment Validation: Use optical microscopy or SEM to visually confirm corrosion pits or surface degradation.

Protocol 2: Assessing Foreign Body Response via Histology

Objective: To characterize the biological tissue response (glial scar formation) to an implanted neural electrode [12].

Materials:

- Fixed neural tissue section containing the electrode tract.

- Primary antibodies: e.g., Anti-GFAP (for astrocytes), Anti-IBA1 (for microglia/macrophages).

- Secondary antibodies with fluorescent tags.

- Nuclear stain (e.g., DAPI).

- Fluorescence microscope.

Methodology:

- Tissue Preparation: Perfuse-fix the animal and extract the brain. Section the tissue containing the implant site into thin slices (e.g., 20-40 μm).

- Immunohistochemistry:

- Permeabilize and block the tissue sections.

- Incubate with primary antibodies against GFAP and IBA1.

- Wash and incubate with fluorescently-labeled secondary antibodies.

- Counterstain with DAPI to label all cell nuclei.

- Imaging and Analysis:

- Image the tissue surrounding the electrode tract using a fluorescence microscope.

- Quantify the intensity of GFAP and IBA1 staining as a function of distance from the implant interface. An increased density and intensity of staining indicates a stronger glial and immune response [12].

Research Reagent Solutions

The table below lists key materials and reagents used in the development and testing of chronic neural interfaces.

| Reagent / Material | Function / Application |

|---|---|

| Platinum-Iridium (Pt/Ir) Alloy | A corrosion-resistant conductive material used for electrode sites in chronic stimulating and recording applications [16]. |

| Iridium Oxide (IrOx) | A conductive coating applied to electrodes to significantly increase their charge injection capacity, improving the efficiency and safety of stimulation [16]. |

| Polydimethylsiloxane (PDMS) | A flexible, biocompatible silicone rubber commonly used as an insulating and encapsulating material for electrode arrays and lead wires [16] [18]. |

| Polyimide / Parylene-C | Flexible polymer coatings used as insulation for microfabricated neural probes, providing a barrier against the physiological environment [16]. |

| Conducting Polymers (e.g., PEDOT, Polypyrrole) | Polymer coatings that can improve electrode performance by lowering impedance and can be functionalized with bioactive molecules to improve tissue integration [19]. |

| Hydrogen Peroxide (Hâ‚‚Oâ‚‚) | Used in in vitro corrosion tests to simulate the oxidative stress present at the implant site during the inflammatory foreign body response [17]. |

Diagrams of Failure Mechanisms and Assessment

Electrode-Tissue Interface Failure Cascade

Corrosion Assessment Workflow

Key Failure Modes Impacting Long-Term Signal Quality

Frequently Asked Questions (FAQs)

What are the primary categories of failure modes for chronic neural interfaces? Failures are typically categorized by their root cause: Biological (e.g., glial scarring, immune response), Material (e.g., corrosion, insulation failure), and Mechanical (e.g., electrode fracture, device migration) [21] [16]. A complementary framework classifies disruptions by their impact on BMI performance and required intervention: Transient, Reversible, Irreversible Compensable, and Irreversible Non-Compensable [22].

Why does signal quality from intracortical microelectrode arrays (MEAs) often degrade over time? Chronic implantation triggers a foreign body response, leading to the formation of an insulating glial scar (astrogliosis) that encapsulates the electrode. This physically separates the recording sites from nearby neurons, increases impedance, and attenuates signal amplitude [21] [16] [23]. This biological encapsulation is a major factor leading to device failure within months to a few years [22] [23].

What are "transient" signal disruptions and how can they be managed? Transient disruptions interfere with recordings on the scale of minutes to hours and may resolve spontaneously. Common causes include micromovements of the array, cognitive fatigue, or stimulation artifacts [22]. Mitigation strategies involve using robust decoder features, data augmentation, and adaptive machine learning models that can accommodate short-term signal instability without requiring full recalibration [22].

How does the mechanical mismatch between a device and brain tissue cause failure? Conventional neural interfaces use rigid materials like silicon or metals, which have a Young's modulus in the GPa range. This is vastly stiffer than brain tissue (kPa range) [23]. This mechanical mismatch causes shear motion at the interface during brain micromovements, leading to chronic inflammation, neuronal death, and ultimately, device encapsulation or failure [16] [23].

Can software or algorithmic strategies compensate for hardware failures? Yes, for certain failure classes. Irreversible Compensable Disruptions cause a persistent decline in signal quality, but their effects can be mitigated algorithmically. Strategies include using in-vivo diagnostics (e.g., impedance spectroscopy) to inform feature selection, information salvage techniques, and adaptive decoding methods to down-weight damaged channels [22].

Troubleshooting Guide: Diagnosing Signal Degradation

Step 1: Classify the Disruption Timeline

Use the following flowchart to categorize the issue based on its observed characteristics. This classification is key to determining the appropriate response.

Step 2: Execute Diagnostic Protocols

Once a disruption category is identified, perform these targeted experimental protocols to diagnose the root cause.

Protocol 1: In-Vivo Electrochemical Impedance Spectroscopy (EIS)

- Purpose: To non-destructively assess the stability of the electrode-tissue interface and differentiate between biological and material failures [22] [16].

- Methodology:

- Setup: Connect the implanted electrode as the working electrode in a three-electrode cell (with a large surface area reference and counter electrode). Use a physiologic saline solution or the natural biological environment.

- Measurement: Apply a small sinusoidal voltage perturbation (e.g., 10 mV RMS) across a frequency range (typically 0.1 Hz to 100 kHz) using a potentiostat.

- Data Analysis: Plot the impedance magnitude and phase versus frequency. Model the data using an equivalent electrical circuit (e.g., a Randles circuit) to extract parameters like interface capacitance and charge transfer resistance.

- Interpretation:

- A steady, gradual increase in low-frequency impedance often indicates stable biological encapsulation [16].

- A sudden, dramatic increase or open-circuit impedance suggests material failure, such as conductor fracture or insulation breakdown [21] [16].

- A significant drop in impedance may indicate a short circuit due to insulation failure.

Protocol 2: Chronic Histological Analysis for Biological Integration

- Purpose: To visually confirm and quantify the biological immune response (gliosis, neuronal loss) upon explant or in terminal experiments [21] [16].

- Methodology:

- Perfusion and Sectioning: Following established protocols, transcardially perfuse the subject with phosphate-buffered saline (PBS) followed by 4% paraformaldehyde (PFA). Extract the brain, post-fix, and section the tissue containing the implant track.

- Immunohistochemistry (IHC): Stain tissue sections with antibodies against:

- NeuN: To label neuronal nuclei and quantify neuronal density/distance from the electrode track.

- GFAP: To label reactive astrocytes and quantify astrogliosis.

- Iba1: To label activated microglia.

- Imaging and Quantification: Use confocal or multiphoton microscopy to image the tissue. Quantify fluorescence intensity and cell counts at varying distances from the electrode interface.

- Interpretation:

Step 3: Review Quantitative Failure Data

Familiarity with reported failure modes from chronic studies provides a benchmark for your own diagnostics. The following table summarizes key metrics and observations.

| Failure Mode / Observed Effect | Key Quantitative Metrics & Signatures | Typical Onset & Duration | Primary Compensatory Strategies |

|---|---|---|---|

| Glial Scarring (Astrogliosis) [21] [16] | - ~100 µm thick glial sheath around electrode [23]- Increased low-frequency impedance (via EIS)- >50% reduction in single-unit yield [22] | Progressive; Months post-implant | - Adaptive decoding [22]- Use of local field potentials (LFPs) [24] |

| Electrode Insulation Failure [16] | - Sudden drop in impedance to near-zero- Increased signal crosstalk/noise- Electrical short circuits during testing | Acute/Unpredictable | Channel de-weighting or exclusion in software [22] |

| Electrode Material Corrosion [16] | - Gradual increase in impedance across all frequencies- Reduced charge injection capacity (CIC)- Visible pitting/defects under SEM | Chronic; Months to Years | - Use of coatings (e.g., Iridium Oxide) [16]- Information salvage algorithms [22] |

| Mechanical Fracture of Leads/Electrodes [21] [16] | - Open-circuit impedance (e.g., >10 MΩ)- Abrupt and permanent loss of all signal on a channel | Acute/Unpredictable | No compensation possible; requires hardware revision [22] |

| Signal Instability (Drift) [22] [24] | - Change in spike waveform shape/amplitude over minutes to days- Decline in decoding performance to chance levels in ~30 min without correction [22] | Transient to Chronic | - Daily decoder recalibration [22]- Manifold alignment techniques [24] |

The Scientist's Toolkit: Key Reagents & Materials

The following table details essential materials and reagents for researching and developing solutions for long-term neural interfaces.

| Research Reagent / Material | Function / Application in Neural Interface Research |

|---|---|

| Conductive Hydrogels [23] | Used as coatings or standalone electrodes to mitigate mechanical mismatch. Provide volumetric capacitance, lowering impedance and improving charge injection. Their tissue-like softness reduces shear-induced inflammation. |

| Iridium Oxide (IrOx) [16] | A highly effective electrode coating material. Significantly increases the charge injection capacity (CIC) of neural stimulation and recording sites, improving signal-to-noise ratio and stimulation efficiency. |

| PEDOT:PSS [23] | A conductive polymer coating for electrodes. Dramatically increases surface area, thereby lowering impedance and boosting CIC. For example, it can increase CIC from 0.83 mC cmâ»Â² (bare Pt) to 2.71 mC cmâ»Â² [23]. |

| Antibodies (GFAP, Iba1, NeuN) [21] | Critical reagents for immunohistochemical characterization of the tissue response post-explant. They allow quantification of glial scarring (GFAP, Iba1) and neuronal loss (NeuN) around the implant. |

| Polyimide / Parylene-C [16] | Flexible polymer materials used for insulation of lead wires and electrode shanks. Their flexibility improves mechanical compliance compared to rigid silicon, though long-term stability in the biotic environment remains a challenge. |

| Multiphoton Microscopy [21] | An in-vivo imaging technique that allows for longitudinal, high-resolution visualization of the device-tissue interface in live animals. It is used to track cellular responses (e.g., glial activation, blood flow) over time without explant. |

| (-)-Isolariciresinol 9'-O-glucoside | Isolariciresinol 9'-O-beta-D-glucoside|522.5 g/mol|RUO |

| 14-(Fmoc-amino)-tetradecanoic acid | 14-(Fmoc-amino)-tetradecanoic acid, MF:C29H39NO4, MW:465.6 g/mol |

Innovative Materials and Engineering Solutions for Stable Interfaces

Advancements in Flexible and Stretchable Bioelectronic Materials

Troubleshooting Guides and FAQs

Frequently Asked Questions

Q1: What are the primary causes of chronic signal degradation in flexible neural interfaces, and how can they be mitigated? Chronic signal degradation is primarily caused by the foreign body response (FBR), leading to inflammation and glial scar formation around the implant, which increases impedance and electrically isolates the electrode [11]. This is often exacerbated by a significant mechanical mismatch between stiff implant materials and soft brain tissue (Young's modulus of 1-10 kPa) [11] [9]. Effective mitigation strategies include:

- Using soft, tissue-like materials with low modulus (e.g., catechol-functionalized polyurethane elastomers with modulus <1 kPa) [25].

- Incorporating anti-inflammatory coatings (e.g., MXene-silk fibroin composites) that actively scavenge reactive oxygen species (ROS) to suppress immune responses [25].

- Designing self-healing materials that can restore conductivity (e.g., up to 90% within 48 hours) after mechanical damage, maintaining signal pathway integrity [25].

Q2: How can I improve the adhesion and durability of conductive coatings on flexible fiber substrates? Delamination of conductive coatings (e.g., metals, conductive polymers) from fiber substrates under repeated strain is a common failure point [26]. To improve adhesion and durability:

- Surface Functionalization: Prior to coating, treat polymer fiber surfaces with oxygen plasma or chemical agents to increase surface energy and create mechanical anchoring sites.

- Adhesion Layers: Use thin metal adhesion layers (e.g., titanium or chromium) beneath primary conductive layers (e.g., gold or platinum) when using metal deposition techniques [26].

- Material Integration: Instead of surface coatings, develop composite fibers where conductive fillers like carbon nanotubes or graphene are integrated directly into the polymer matrix via melt blending or in-situ polymerization [26]. This enhances the interfacial strength and makes the conductivity more resilient to cyclic bending and stretching.

Q3: My flexible bioelectronic device is producing noisy signals under movement. What could be the cause? Noise under movement is often caused by motion artifacts due to unstable contact between the device and the dynamic tissue surface [27]. This can be addressed by:

- Enhancing conformability through ultra-thin, stretchable designs that move with the tissue [27].

- Employing strain-insensitive materials. For example, novel gradient interface materials that transition from soft to stiff have been shown to provide "near perfect immunity to inaccuracies caused by strain and motion" [27].

- Ensuring stable device encapsulation to protect the conductive elements from moisture and biofluids, which can cause signal shorts or variations [25].

Q4: What are the best practices for troubleshooting a complete failure in a flexible bioelectronic sensor? Follow a systematic approach to isolate the problem [28] [29]:

- Verify Power and Connections: Check for loose connections, damaged cables, or compromised interconnects. Use a multimeter to confirm voltage levels at critical points in the circuit [28].

- Inspect for Physical Damage: Look for microcracks in conductive traces, delamination of layers, or blown fuses. A visual inspection under a microscope can often reveal these issues [28] [29].

- Check Signal Path Integrity: Use an oscilloscope to trace the signal from the input (e.g., the electrode site) through the entire system to identify where the signal is lost or degraded [29].

- Test Individual Components: If possible, isolate and test individual components like electrodes and substrates to identify the faulty module.

Troubleshooting Guide: Common Experimental Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Rising Electrode Impedance | Glial scar formation (Foreign Body Response), material corrosion [11]. | Utilize soft, biocompatible materials; incorporate anti-inflammatory drug-eluting coatings [25] [11]. |

| Conductive Coating Delamination | Poor adhesion, repeated mechanical strain [26]. | Improve surface pretreatment; use composite conductive fibers instead of coated ones [26]. |

| Unstable Signal under Strain | Mechanical mismatch, motion artifacts [27]. | Design stretchable, strain-insensitive conductors; use gradient interface materials [27]. |

| Sudden Loss of Signal | Broken wire or interconnect, fuse failure, cracked conductive trace [28]. | Perform visual inspection; use a multimeter to check for continuity and blown fuses; repair with conductive epoxy or re-fabricate [28]. |

| Reduced Device Lifespan in Biofluids | Degradation of encapsulation, moisture penetration [25]. | Implement robust, self-healing encapsulation layers; explore biomimetic mineralization barriers to enhance fluid resistance [25]. |

Experimental Protocols & Performance Data

Detailed Methodology: Fabrication of a Self-Healing Conductive Hydrogel

This protocol outlines the synthesis of a dynamic borate ester-crosslinked conductive hydrogel for neural interfaces, as featured in recent literature [25].

Objective: To create an ultra-tough, self-healing hydrogel with high conductivity for stable neural signal acquisition.

Materials:

- Monomer Solution: Dopamine-modified hyaluronic acid (HA-DOPA).

- Crosslinker: Borax (Sodium tetraborate).

- Conductive Medium: Phosphate Buffered Saline (PBS) or cell culture medium.

- Gelling Agent: Polyvinyl alcohol (PVA) solution.

Procedure:

- Preparation: Dissolve HA-DOPA in PBS to a final concentration of 5% (w/v). Separately, prepare a 2% (w/v) Borax solution in deionized water.

- Mixing: Slowly add the Borax solution to the HA-DOPA solution under constant stirring at room temperature. Use a volume ratio of 1:10 (Borax:HA-DOPA).

- Gelation: Continue stirring for 30 minutes until a homogeneous mixture is achieved. Transfer the solution to a mold and allow it to crosslink for 2 hours at 37°C to form a stable hydrogel.

- Post-processing: The resulting hydrogel can be integrated onto a soft elastomer substrate and coated with an anti-inflammatory layer (e.g., MXene-silk fibroin) to form the complete bioadhesive interface [25].

Key Characterization:

- Mechanical Testing: Perform cyclic tensile tests to measure toughness (target: ~420 MJ/m³).

- Electrical Characterization: Measure impedance and conductivity (target: ~1.2 S/cm) before and after inducing mechanical damage to validate self-healing properties.

- In Vitro Validation: Test in cell culture to confirm reduced inflammatory response and cytotoxicity.

Quantitative Performance of Advanced Materials

The table below summarizes key performance metrics for recent flexible bioelectronic materials, providing a benchmark for experimental outcomes.

Table: Performance Comparison of Flexible Bioelectronic Materials

| Material Platform | Key Feature | Electrical Conductivity | Mechanical Property | Chronic Performance (in vivo) | Key Reference Metric |

|---|---|---|---|---|---|

| Self-Healing Bioadhesive Interface [25] | Dynamic borate ester bonds, anti-inflammatory coating | 1.2 S/cm (under 100% strain) | Toughness: 420 MJ/m³ | Signal stability: 30 days; Fibrous capsule: 28.6 ± 5.4 μm | Signal-to-Noise Ratio (SNR): 37 dB |

| MXene-Silk Fibroin Coating [25] | ROS scavenging, suppresses immune response | N/A (Surface coating) | Modulus similar to neural tissue | Reduces capsule thickness to one-third of traditional materials | 40% improvement in motion artifact suppression |

| Gradient Interface Material [27] | Aerosol-printed, seamless soft-to-stiff transition | Stable under strain | Highly stretchable | Near perfect immunity to motion artifacts | Accurate vitals monitoring under movement |

| Fiber-Based Capacitive Sensor [26] | Textile-integrated, cross-layer structure | Capacitance change with pressure | High flexibility, lightweight | Reduced motion artifacts in wearable settings | High pressure sensitivity |

The Scientist's Toolkit: Research Reagent Solutions

Table: Essential Materials for Flexible Bioelectronics Research

| Item | Function/Application |

|---|---|

| Catechol-functionalized Polymers (e.g., polyurethane) | Forms soft, tissue-adhesive substrate layers that mimic the modulus of brain tissue (<1 kPa) [25]. |

| Dynamic Crosslinkers (e.g., Borax) | Creates reversible bonds (e.g., borate ester bonds) in hydrogels, enabling self-healing properties and ultra-high toughness [25]. |

| Conductive Nanomaterials (CNTs, Graphene, MXene) | Serves as conductive fillers in composites or coatings to provide electrical pathways while maintaining flexibility [26]. |

| Anti-inflammatory Agents (e.g., Silk Fibroin) | Used as a biocompatible matrix for drug delivery or as an active coating to suppress the foreign body response by scavenging ROS [25]. |

| Soft Elastomers (e.g., Polydimethylsiloxane - PDMS, Poly(styrene-butadiene-styrene) - SBS) | Acts as an encapsulant or stretchable substrate for housing electronic components and conforming to dynamic tissues [25] [26]. |

| L-Asparagine-N-Fmoc,N-beta-trityl-15N2 | L-Asparagine-N-Fmoc,N-beta-trityl-15N2, CAS:204633-98-7, MF:C38H32N2O5, MW:598.7 g/mol |

| 4-Aminodiphenylamine sulfate | 4-Aminodiphenylamine sulfate, MF:C12H14N2O4S, MW:282.32 g/mol |

Experimental Workflow and Signaling Pathways

Neural Interface Stability Workflow

The following diagram illustrates the integrated experimental workflow for developing and validating a stable flexible neural interface, from material design to functional assessment.

Foreign Body Response Signaling Pathway

This diagram maps the key biological signaling pathways involved in the foreign body response to implanted electrodes and the points where advanced materials intervene to improve biocompatibility.

Troubleshooting Guides

Common Issues and Solutions for High-Density Neural Probes

| Problem Category | Specific Symptom | Possible Cause | Solution | Reference |

|---|---|---|---|---|

| Hardware Connection | Basestation detected but no probes recognized [30] | Probe not properly seated in headstage ZIF connector [30] | Re-seat the probe in the headstage connector [30] | [30] |

| Solid yellow LED on headstage after startup [31] | Detected probe is not configured with calibration files [31] | Use software tools (e.g., probeConfig) to load probe-specific calibration files [31] |

[31] | |

| "Firmware version mismatch" message [30] | Communication issue between software and hardware; often resolves after probe detection [30] | Ensure probes are detected (green indicator). Ignore message if probes are functional [30] | [30] | |

| Signal Quality | High noise levels [32] | Poor soldering connections [32] | Review and re-solder connections using proper technique [32] | [32] |

| Saturated LFP signals with external reference (multi-basestation setups) [30] | Grounding issue between multiple PXI basestations [30] | Switch reference type from "External" to "Tip" or "Ground" [30] | [30] | |

| Mechanical & In Vivo | Progressive signal loss from neurons over time [33] | Brain motion relative to the probe (brain drift) [33] | Use high-density sites (NP2.0) and post-hoc software motion correction [33] | [33] |

| Error codes (e.g., Philips Error 30, GE "No Reference Position Signal") [34] | Mechanical trauma to probe tip or internal motor; failed internal seals [34] | Visually inspect for damage. For mechanical 3D probes, may require professional repair [34] | [34] |

Probe Selection and Configuration for Chronic Recordings

| Probe Type | Key Characteristics | Recommended Use Case | Configuration Tip for Signal Fidelity |

|---|---|---|---|

| Neuropixels 1.0 NHP | 45-mm long shank; 4,416 sites; 384 simultaneously recordable channels [35] | Deep brain structures in non-human primates; large animal models [35] | Programmable site selection allows surveying brain regions to optimize positioning post-insertion [35]. |

| Neuropixels 2.0 | Miniaturized; ~1.1g for 2-probe headstage; 15 µm site spacing; aligned columns [33] | Chronic, long-term recordings in freely moving mice; stable neuron tracking over months [33] | Use the dense, linearized site geometry to enable post-hoc motion correction algorithms [33]. |

| Neuropixels Ultra | Ultra-high site density (6 µm site-to-site spacing) [36] | Discriminating axonal signals; classifying cortical interneuron types [36] | Leverages small spatial "footprints" of waveforms to improve neuron classification accuracy [36]. |

| 4-Shank NP 2.0 | 5,120 sites per probe; records from a ~1 x 10 mm plane [33] | Brain structures with complex geometries (e.g., layered cortex, hippocampus) [33] | Configure switches to sample sites across shanks, covering a 2D plane for population dynamics [33]. |

Frequently Asked Questions (FAQs)

Q1: How can I improve the stability of recordings from the same neurons over weeks or months?

Achieving chronic stability requires a combination of hardware and software solutions. The miniaturized, high-density Neuropixels 2.0 probe is designed for this purpose. Its dense (15 µm spacing), vertically aligned sites allow specialized analysis software to perform post-hoc motion correction. This algorithm automatically corrects for brain movements relative to the probe, which is the primary cause of losing track of neurons over time. With this approach, recordings from the same identified neurons have been demonstrated for over two months [33].

Q2: What are the best practices for selecting recording sites and references during an experiment?

- Site Selection: The strategy should match your scientific goal. Use the "Short" configuration to record from 384 consecutive channels for maximum vertical density. Use the "Long" configuration (every other channel) to cover a larger brain area with lower density. For complex targets, use "Multi" mode to create custom channel ranges across different shanks or banks [31].

- Reference Selection: The choice depends on your signal of interest.

- External (default): References to a dedicated pad connected to a wire in saline or a skull screw. This is best for LFP analysis [30].

- Tip: References to a large pad at the probe tip. This often reduces noise but can cause LFP signal leakage across channels. Ensure some channels are outside the brain for offline LFP subtraction [30].

- Ground (NP2.0): Similar to External, but with an internal connection between ground and reference, eliminating the need for a bridge wire [30].

Q3: My probe is detected, but the signal is noisy. What are the first things I should check?

First, verify that the probe's calibration files are correctly installed in the designated folder on your acquisition computer. Using an uncalibrated probe can lead to poor signal quality [30]. Second, inspect all physical connections. Improper soldering is a common source of noise, so check all solder points for quality and continuity [32]. Finally, ensure the probe's reference pad is properly connected to your system's ground, either via a wire bridge (for External reference) or internally (for Ground reference) [30].

Q4: What specific advantages do the newest high-density probes offer for cell-type classification?

Ultra-high-density probes like Neuropixels Ultra significantly improve cell-type classification by capturing the detailed spatial "footprint" of a neuron's action potential waveform. With a very small site-to-site spacing (6 µm), these probes can detect waveforms with small spatial extents, such as those from axons. This high-resolution data provides additional features that can be used to discriminate between different, genetically identified cortical interneuron types with approximately 80-85% accuracy [36].

Experimental Protocols for Chronic Signal Fidelity

Protocol: Post-Hoc Motion Correction for Long-Term Stability

Purpose: To enable recording from the same individual neurons across days and weeks by compensating for brain motion relative to the probe.

Principle: Brain motion, primarily along the probe's insertion axis, causes the same neuron to be recorded on different sites over time. High-density, linearly aligned recording sites (as in Neuropixels 2.0) allow software to track these shifts and reassemble the neuron's consistent signal [33].

Workflow:

- Implant: Chronically implant a high-density probe (e.g., Neuropixels 2.0) with sites aligned in a linear column [33].

- Record: Acquire neural data across multiple sessions over days or weeks [33].

- Detect Shifts: Apply algorithms (e.g., Kilosort motion correction) that compute the correlation of activity across sites over time to infer vertical motion tracks [33].

- Align Data: The software uses these tracks to shift the data, realigning the activity of each neuron to a common reference frame [33].

- Sort Spikes: Perform spike sorting on the motion-corrected data to identify and track individual units stably [33].

Motion Correction Workflow

Protocol: Optimizing Site Selection for Multi-Region Recording

Purpose: To strategically configure a limited number of recording channels (e.g., 384 per NP 1.0 NHP probe) to monitor activity from multiple brain regions of interest simultaneously.

Principle: Long probes like the Neuropixels 1.0 NHP (45 mm) span numerous brain areas. Its programmable switch matrix allows users to select a subset of its 4,416 sites for recording, enabling flexible experimental designs without physically moving the probe [35].

Workflow:

- Insert Probe: Position the long shank to traverse all target brain regions [35].

- Initial Survey: Use the acquisition software to sequentially enable different sets of sites along the entire shank to map electrophysiological landmarks (e.g., white matter layers, region-specific firing patterns) [35].

- Define Configuration: Based on the survey, create a custom "Electrode Preset" that enables sites specifically within your regions of interest. For example, select 128 sites in the cortex, 128 in the thalamus, and 128 in the midbrain [30] [31].

- Save & Record: Save this preset and begin the experiment. The system will now simultaneously record from all selected sites across the different brain regions [30].

The Scientist's Toolkit: Research Reagent Solutions

Table: Essential Materials for High-Density Neural Recording Experiments

| Item | Function | Example / Specification |

|---|---|---|

| Neuropixels Probes | Core recording device; various models for different species and applications. | Neuropixels 1.0 (mouse), NP 1.0 NHP (macaque), NP 2.0 (chronic mouse), NP Ultra (high cell-type yield) [36] [35] [33]. |

| Calibration Files | Probe-specific files for accurate signal conditioning. Essential for data quality. | <probe_serial_number>_gainCalValues.csv; must be placed in the correct directory for the acquisition software [30]. |

| PXI Chassis & Basestation | High-performance data acquisition system for streaming data from the probes. | NI PXIe-1071 chassis; Neuropixels basestation (acquires data from up to 4 probes) [30]. |

| Acquisition Software | Software to configure probes, select channels, visualize data, and record. | Open Ephys GUI, SpikeGLX, or Trodes [32] [30] [31]. |

| Reference Wire | Provides a stable electrical reference for the recorded neural signals. | Immersed in saline above the brain (acute) or connected to a skull screw (chronic) [30]. |

| Probe Recovery Fixture | Custom 3D-printed hardware to protect the probe during chronic implants, allowing for recovery and re-use. | Enables probe retrieval after experiment; 7 out of 8 probes were successfully recovered using such hardware [33]. |

| Sodium formononetin-3'-sulfonate | Sodium formononetin-3'-sulfonate, MF:C16H11NaO7S, MW:370.3 g/mol | Chemical Reagent |

| Biotin-PEG2-C1-aldehyde | Biotin-PEG2-C1-aldehyde, MF:C16H27N3O5S, MW:373.5 g/mol | Chemical Reagent |

FAQs and Troubleshooting Guides

This technical support center addresses common challenges in the fabrication and application of ultramicroelectrodes (UMEs) for chronic neural interfaces. The guidance is framed within the broader thesis of improving long-term signal fidelity in neural recording and stimulation.

Frequently Asked Questions (FAQs)

1. What are the key advantages of using amorphous silicon carbide (a-SiC) for UME fabrication? a-SiC offers exceptional chronic stability as a primary structural element and encapsulation material for microelectrode arrays (MEAs). Its high intrinsic stiffness and flexibility as a thin-film minimize tissue damage and foreign body response. a-SiC films are well-tolerated in the cortex and highly resistant to corrosion in saline, contributing to device longevity [37]. MEAs fabricated with a-SiC can have shank cross-sectional areas less than 60 μm² and transverse dimensions under 10 μm, which is associated with reduced gliosis and improved recording quality [37].

2. Why is precise control over UME tip exposure critical for single-cell recording? Controllable tip exposure is fundamental for balancing signal fidelity and electrochemical performance. Excessive exposure leaves the electrode susceptible to environmental interference and noise, reducing signal fidelity. Insufficient exposure results in high electrode impedance, which diminishes the signal-to-noise ratio and weakens the ability to distinguish low-amplitude signals from neurons [38]. Precise control ensures an optimal contact area with the intracellular environment.

3. Which low-impedance coatings are used to improve UME performance? Titanium Nitride (TiN) and Sputtered Iridium Oxide (SIROF) are common coatings used to enhance UME performance. These porous coatings significantly increase the effective surface area of the electrode sites, which lowers impedance and allows for higher charge injection capacities, which is crucial for both recording and stimulation applications [37].

4. What are the primary failure modes for chronically implanted neural interfaces? Implant failures are often categorized as technological, mechanical, or biological.

- Technological/Mechanical: These include insulation failure of packaging or lead wires, delamination of thin-film structures, fracture of interconnects, and corrosion of electrode sites [16] [39].

- Biological: The Foreign Body Response (FBR) is a major challenge. This involves activation of microglia and astrocytes, leading to the formation of a glial scar that insulates the electrode from nearby neurons, increasing impedance and degrading signal quality over time [37] [39].

5. How does electrode size influence the chronic foreign body response? Research indicates that the severity of the foreign body response is greatly reduced with implanted microelectrodes that have a maximum transverse cross-sectional dimension of less than approximately 10 μm [37]. Smaller shanks cause less insertion trauma and chronic tissue disruption, leading to minimal gliosis and better long-term neuronal viability around the implant site [37].

Troubleshooting Guides

Problem: High Electrode Impedance High impedance leads to poor signal-to-noise ratio in recording and limited charge injection for stimulation.

- Potential Cause: Inadequate low-impedance coating or overly small geometric surface area of the electrode site.

- Solution:

- Apply or optimize a low-impedance coating such as TiN or SIROF. These can reduce 1 kHz impedance from ~2.8 MΩ (for a 100 μm² Au site) to below 100 kΩ [37].

- Ensure the tip exposure length is precisely controlled. If the exposed conductive surface is too small, impedance will be inherently high [38].

- Prevention: Incorporate low-impedance coatings during the fabrication process and validate electrode impedance in phosphate-buffered saline (PBS) before implantation [37].

Problem: Uncontrollable or Inconsistent UME Tip Exposure The inability to reliably define the exposed tip functional structure results in variable performance and poor signal fidelity.

- Potential Cause: Reliance on traditional sealing methods like wax, which have poor controllability over thickness and coverage [38].

- Solution: Implement a direct-write microplasma jet processing technique. This method uses a high-voltage atmospheric microplasma jet to selectively etch protective coatings (e.g., Diamond-Like Carbon) from the UME tip with submicron precision [38] [40] [41].

- Prevention: Use dense, chemically stable protective coatings like DLC that are amenable to highly selective etching processes.

Problem: Rapid Signal Degradation Following Implantation A decline in recording quality or stimulation efficacy over days or weeks.

- Potential Cause: The foreign body response (FBR), leading to glial scar formation that isolates the electrode from neurons [39].

- Solution:

- Prevention: Ensure a smooth, clean implant surface and employ surgical techniques that minimize insertion trauma and vascular damage.

Problem: Delamination of Thin-Film Metal Traces or Encapsulation A failure of the layered structure of the microelectrode, leading to short or open circuits.

- Potential Cause: Poor adhesion between material layers or stress mismatch due to film morphology.

- Solution:

- For a-SiC devices, optimize Plasma Enhanced Chemical Vapor Deposition (PECVD) parameters (e.g., temperature, RF power, pressure) to manage intrinsic film stress [37].

- Implement rigorous adhesion promotion protocols and stress-relieving structural designs.

- Prevention: Perform thorough morphological and stress characterization (e.g., using SEM, AFM, stress analyzers) during process development [37].

Experimental Protocols and Data

Detailed Methodology: Fabrication of a-SiC Microelectrode Arrays

This protocol outlines the key steps for creating flexible MEAs using amorphous silicon carbide [37].

- Substrate Preparation: Begin with a prime-grade 100 mm Si (100) wafer.

- Release Layer Deposition: Spin-coat an approximately 1 μm layer of polyimide (e.g., HD Microsystems, PI 2610) onto the silicon wafer. Cure at 350°C for one hour under a nitrogen atmosphere.

- First a-SiC Deposition: Deposit a 2 μm thick a-SiC film via Plasma Enhanced Chemical Vapor Deposition (PECVD) over the polyimide release layer.

- Metallization Patterning:

- Use a two-layer liftoff photolithography process (e.g., LOR 5A and S1813 photoresist) to define the metal trace pattern on the a-SiC.

- Deposit metal layers via DC sputtering. A common structure is Ti/Au/Ti (30 nm/250 nm/30 nm) or Ti/Au/Pt/Ti for enhanced stability.

- Perform metal lift-off by immersing the wafer in an appropriate solvent (e.g., EBR-PG).

- Device Encapsulation: Deposit a second 2 μm layer of a-SiC via PECVD over the metal traces, fully encapsulating them.

- Via Etching: Use Reactive Ion Etching (RIE) with an SF6 plasma to open vias through the top a-SiC layer and the upper titanium layer, defining the electrode sites and bond pads.

- Device Singulation: Protect the MEA superstructure with a thick photoresist layer and use a second SF6 RIE step to cut the individual arrays from the wafer.

- Release: Soak the wafer in deionized water at 87°C to dissolve the polyimide release layer, freeing the flexible a-SiC MEAs from the rigid silicon substrate.

Quantitative Performance Data

Table 1: Electrochemical Performance of 100 μm² Electrode Sites with Different Coatings [37]

| Electrode Material | Typical 1 kHz Impedance | Charge Injection Capacity (≥) |

|---|---|---|

| Gold (Au) | ~2.8 MΩ | - |

| Titanium Nitride (TiN) | <100 kΩ | 3 mC/cm² |

| Sputtered Iridium Oxide (SIROF) | <100 kΩ | 3 mC/cm² |

Table 2: Key Characteristics of Probe Materials for Intracortical Recording [37] [39]

| Material | Typical Use | Key Advantages | Key Challenges |

|---|---|---|---|

| Amorphous SiC (a-SiC) | Structure & Encapsulation | High chronic stability, flexible, strong, low FBR, corrosion resistant | Deposition parameter optimization required |

| Diamond-Like Carbon (DLC) | Protective Coating | Superior mechanical properties, biocompatible, biochemically inert [38] | Requires specialized etching (e.g., microplasma) |

| Silicon | Micromachined Probes | High-density integration, well-established processes | Brittle, can trigger significant FBR |

| Polyimide | Flexible Probes | Flexible, biocompatible | Can absorb moisture, potentially degrading over time |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for UME Fabrication and Characterization

| Item Name | Function/Application |

|---|---|

| Polyimide (PI 2610) | Sacrificial release layer and flexible substrate material [37]. |

| a-SiC PECVD Gases (SiH4, CH4, Ar) | Precursor gases for depositing amorphous silicon carbide thin films [37]. |

| Titanium (Ti) & Gold (Au) Sputtering Targets | For creating conductive traces and interconnects within the neural probe [37]. |

| TiN or SIROF Sputtering Targets | For depositing low-impedance, high charge-injection capacity coatings on electrode sites [37]. |

| Phosphate Buffered Saline (PBS) | In-vitro electrochemical characterization (impedance spectroscopy, cyclic voltammetry) to simulate physiological conditions [37] [38]. |

| Diamond-Like Carbon (DLC) | A dense, electrochemically stable, and biocompatible film for UME insulation and protection [38] [40]. |

| SF6 Gas | Etchant gas for Reactive Ion Etching (RIE) of a-SiC layers to define device geometry and vias [37]. |

| PC-Biotin-PEG4-PEG3-Azide | PC-Biotin-PEG4-PEG3-Azide, MF:C39H63N9O14S, MW:914.0 g/mol |

| Propargyl-PEG4-S-PEG4-acid | Propargyl-PEG4-S-PEG4-acid, MF:C22H40O10S, MW:496.6 g/mol |

Workflow and Schematic Diagrams

Technical Support Center: Troubleshooting Guides and FAQs

This technical support center provides targeted solutions for researchers developing and utilizing multifunctional neural interfaces. The guidance is framed within the critical context of improving chronic signal fidelity, a central challenge in long-term neural interface studies.

Frequently Asked Questions (FAQs)

Q1: Why does the signal-to-noise ratio (SNR) of my recorded neural signals degrade over weeks of implantation?

The most common cause of chronic SNR degradation is the foreign body response (FBR), which leads to the formation of an insulating glial scar around the implant [16]. This fibrotic tissue increases the physical distance between neurons and recording sites, attenuating signal strength. Furthermore, mechanical mismatch between rigid probes and soft neural tissue can cause micromotions that exacerbate this inflammatory response and directly damage nearby neurons [42] [43]. To mitigate this, adopt probes made from flexible, compliant materials like polyimide, SU-8, or conductive polymers such as PEDOT:PSS, which significantly reduce chronic inflammation and improve long-term stability [42] [43].

Q2: How can I minimize the large electrical artifacts that overwhelm neural recordings during simultaneous electrical stimulation?

Stimulation artifacts pose a significant challenge for closed-loop systems. Effective strategies include:

- Material Engineering: Coat stimulating electrodes with high-charge-injection-capacity materials like iridium oxide (IrOx) or PEDOT [43]. These materials allow for lower stimulation voltages by increasing the effective surface area, thereby reducing the artifact's amplitude [43].

- Spatial Separation: Physically isolate the recording and stimulating electrodes where possible. The use of multifunctional probes with dedicated, separate sites for each function helps minimize direct signal coupling [43].

- Blanking Circuits: Implement a hardware "blanking" circuit that temporarily disconnects the recording amplifier during the stimulation pulse to prevent saturation [16].

Q3: Our wireless, fully implantable device is experiencing unexpected power drain and data transmission errors. What could be the cause?

Power and data transmission are major hurdles for implanted systems. Ensure that the inductive coupling coils for power transfer and data communication are properly aligned and have minimal tissue thickness between them, as this dramatically affects efficiency [16]. High power consumption often stems from wireless data transmission; consider implementing onboard data compression or signal processing to reduce the required bandwidth [16]. Also, adhere to safety standards, as power density in the body must be kept below 80 mW/cm² to prevent tissue damage from heating [16].

Q4: What are the best practices for achieving precise, localized drug delivery without backflow in a miniaturized neural probe?

To prevent backflow and ensure targeted delivery:

- Innovative Pump Design: Utilize peristalsis-inspired micropumps that create unidirectional flow. These systems, often made from soft materials, use sequential actuation to push fluid forward reliably, mimicking the human gastrointestinal tract [44].

- Nozzle-Diffuser Microchannels: Integrate microchannels with a tapered nozzle-diffuser design. This structure provides flow directionality, offering higher resistance to backflow than forward flow [44].

- Integrated Microfluidics: Employ probes with built-in microfluidic channels that terminate in close proximity to recording electrodes. This allows for localized drug application and simultaneous recording of neural responses [43].

Troubleshooting Guide: Chronic Signal Fidelity

This guide addresses the most common failure modes that impact long-term signal quality.

| Problem Area | Specific Issue & Symptoms | Recommended Solution | Key References |

|---|---|---|---|

| Biological Integration | Increasing electrode impedance & low-amplitude units. Symptom: Gradual decline in viable unit count over weeks. | → Use softening neural electrodes that become more compliant after implantation (e.g., body temperature-triggered) [42].→ Apply anti-inflammatory nanogel coatings to probes to minimize glial activation [43].→ Utilize tissue-adhesive hydrogels to reduce micromotions [42]. | [42] [43] |

| Electrode-Tissue Interface | Low signal-to-noise ratio (SNR) & electrical instability. Symptom: Unstable baseline, increased noise. | → Modify electrodes with nanomaterials (e.g., graphene, CNTs) or conductive polymers (PEDOT) to improve charge transfer efficiency and lower impedance [42] [43].→ Use flexible cuff electrodes (e.g., self-closing designs) to ensure stable, conformal contact with nerves [42]. | [42] [43] |